Choosing the right adhesive can make or break your project. Two of the most commonly compared options are cyanoacrylate glue (CA) and epoxy. While both are popular in industrial and consumer applications, each excels under different conditions.

As a trusted adhesive manufacturer, ZDS™ delivers innovative bonding solutions tailored to specific material challenges, offering both CA and epoxy options for high-performance requirements.

Key Differences Between Cyanoacrylate and Epoxy

Understanding the fundamental distinctions between these adhesives helps you choose wisely.

Composition and Cure Mechanism

- Cyanoacrylate: A single-component, fast-acting adhesive that cures instantly upon exposure to moisture.

- Epoxy: A two-part adhesive (resin + hardener) requiring mixing, with a slower cure time.

Cure Time and Handling

- CA Glue: Sets in seconds to minutes, ideal for quick fixes.

- Epoxy: Requires 5 minutes to several hours to cure, offering longer workability.

Bond Strength and Durability

- CA Strength: Excellent tensile strength for small, rigid parts.

- Epoxy Strength: Superior structural bonding, impact resistance, and chemical stability.

Best Applications for Each Adhesive

When to Use Cyanoacrylate Glue

Cyanoacrylate glue is ideal for:

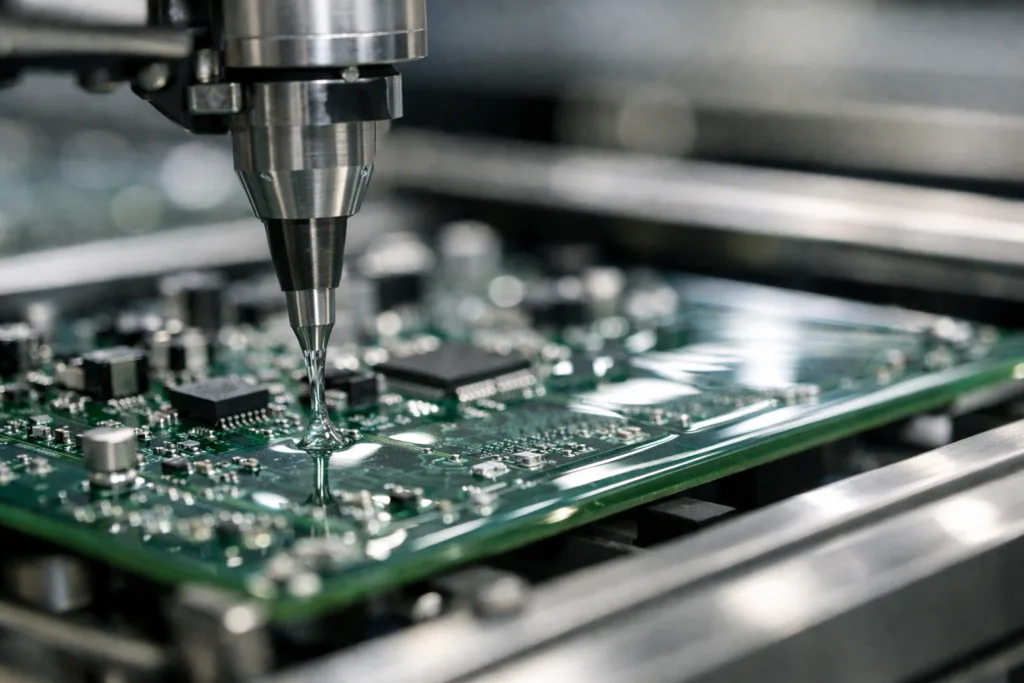

- Small plastic or metal components

- Electronics, medical devices, and hobby crafts

- Low-stress, precision applications

Benefits:

- Fast curing

- Minimal surface preparation

- Excellent for non-porous materials

When to Use Epoxy Adhesive

Epoxy is recommended for:

- Structural bonding of metal, composite, or concrete

- Load-bearing or high-vibration assemblies

- Outdoor or chemically exposed environments

Benefits:

- Exceptional strength and durability

- Gap-filling capabilities

- Strong adhesion to porous and non-porous surfaces

CA vs Epoxy Strength Comparison

In terms of CA vs epoxy strength, epoxy generally wins for structural integrity. However, cyanoacrylate has its place in speed-sensitive, light-duty scenarios.

| Property | Cyanoacrylate | Epoxy |

|---|---|---|

| Cure Speed | Seconds to Minutes | 5 Minutes to 24 Hours |

| Bond Strength | Medium to High | Very High |

| Gap Filling | Poor | Excellent |

| Temperature Resistance | Moderate | High |

| Flexibility | Low | High |

ZDS™: Adhesive Innovation You Can Trust

Whether your application demands fast bonding adhesive or epoxy for structural bonding, ZDS™ offers specialized formulations engineered for performance, speed, and reliability.

With decades of expertise in industrial adhesives, ZDS™ supports clients across automotive, electronics, aerospace, and consumer goods sectors. From quick CA fixes to heavy-duty epoxy solutions, we provide bonding technologies that meet the highest industry standards.

Frequently Asked Questions

Is cyanoacrylate glue stronger than epoxy?

No, epoxy generally offers higher structural strength, but CA glue is better for quick, small-scale fixes.

Can you use epoxy and CA glue together?

Yes, in some applications, CA can be used for temporary positioning before epoxy cures fully.

Which adhesive is best for metal to plastic bonding?

Epoxy is typically more reliable for mixed material bonding like metal to plastic.

Final Call to Action

Whether you’re comparing cyanoacrylate glue vs. epoxy for your next project, consider your performance priorities: speed, strength, or versatility. For both fast-setting and high-strength adhesive solutions, ZDS™ provides trusted products backed by deep technical insight.