Industrial Structural Adhesive for High-Performance Bonding

Reliable, High-Strength Adhesive Solutions for Electronics, Automotive, Aerospace & More

- OEM/ODM

- Custom Formulas

- Global Bulk Supply

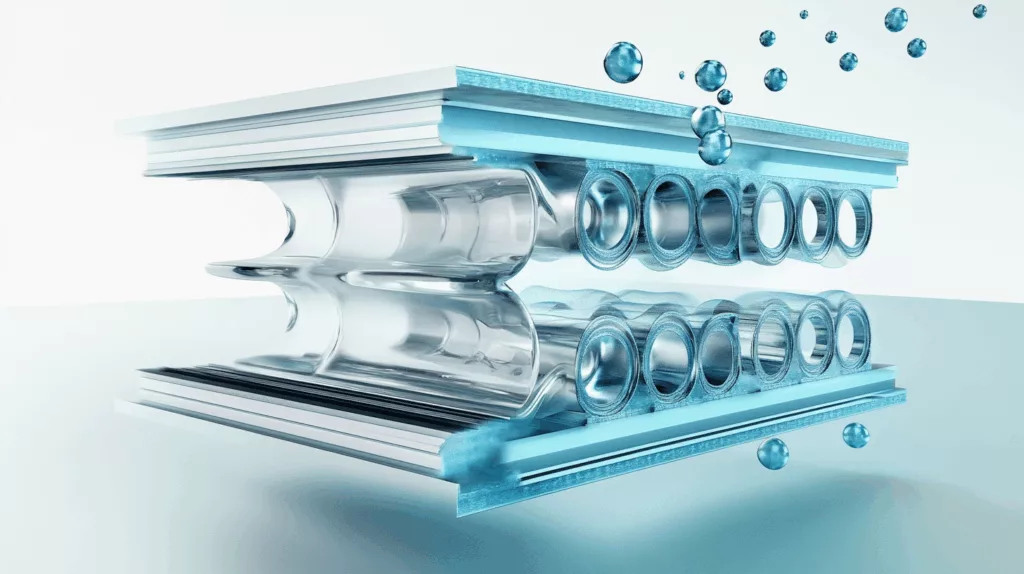

What is Structural Adhesive?

Structural adhesive refers to a high-strength bonding agent engineered to permanently join load-bearing materials such as metals, plastics, composites, and ceramics. Unlike mechanical fasteners, structural adhesives distribute stress evenly across bonded surfaces, providing durability, vibration resistance, and design flexibility.

These adhesives are essential in industries where performance and long-term reliability are non-negotiable.

Introduction to ZDS™ Structural Adhesive

ZDS™ is a top choice for bonding solutions with its advanced acrylic glue. It uses the latest in adhesive tech, making it a leader in the automotive, woodworking, and metal sectors. Our epoxy-based solutions offer top-notch bonding across a variety of materials and uses.

| Attribute | Details |

|---|---|

| Type | Metal bonding |

| Feature | Low odor |

| Model | ZDS450 |

| Color A/B | Blue/light green |

| Volume ratio A:B | 1:1 |

| Pot life /Min | 3 |

| Initial solidification time /Min | 10 |

| Full solidification time /H | 12 |

| Shear strength (carbon steel) Mpa | 22 |

| Temperature range ℃ | -50~120 |

| Packaging | 50ml/400ml |

| Shelf life | 9-12 months |

| Attribute | Details |

|---|---|

| Type | Metal bonding |

| Feature | General bonding |

| Model | ZDS456 |

| Color A/B | Blue/red |

| Volume ratio A:B | 1:1 |

| Pot life /Min | 3 |

| Initial solidification time /Min | 30 |

| Full solidification time /H | 12 |

| Shear strength (carbon steel) Mpa | 25 |

| Temperature range ℃ | -50~120 |

| Packaging | 50ml/400ml |

| Shelf life | 9-12 months |

| Attribute | Details |

|---|---|

| Type | Metal bonding |

| Feature | Low odor/flame retardant |

| Model | ZDS470 |

| Color A/B | Blue/White |

| Volume ratio A:B | 1:1 |

| Pot life /Min | 5 |

| Initial solidification time /Min | 30 |

| Full solidification time /H | 24 |

| Shear strength (carbon steel) Mpa | 18 |

| Temperature range ℃ | -50~120 |

| Packaging | 50ml/400ml |

| Shelf life | 9-12 months |

| Attribute | Details |

|---|---|

| Type | Metal bonding |

| Feature | Long Pot life |

| Model | ZDS805 |

| Color A/B | Light green/light red |

| Volume ratio A:B | 1:1 |

| Pot life /Min | 15 |

| Initial solidification time /Min | 30 |

| Full solidification time /H | 24 |

| Shear strength (carbon steel) Mpa | 25 |

| Temperature range ℃ | -50~120 |

| Packaging | 50ml/400ml |

| Shelf life | 9-12 months |

| Attribute | Details |

|---|---|

| Type | Metal bonding |

| Feature | High temperature resistance |

| Model | ZDS332 |

| Color A/B | Clear |

| Volume ratio A:B | —— |

| Pot life /Min | 120 |

| Initial solidification time /Min | 3 |

| Full solidification time /H | 20min @ 130 ℃ |

| Shear strength (carbon steel) Mpa | 18 |

| Temperature range ℃ | -50~180 |

| Packaging | 1kg |

| Shelf life | 9-12 months |

| Attribute | Details |

|---|---|

| Type | Composite material bonding |

| Feature | General bonding |

| Model | ZDS14167 |

| Color A/B | Creamy white/blue |

| Volume ratio A:B | 10:1 |

| Pot life /Min | 10 |

| Initial solidification time /Min | 15 |

| Full solidification time /H | 12 |

| Shear strength (carbon steel) Mpa | 25 |

| Temperature range ℃ | -50~150 |

| Packaging | 50ml/490ml |

| Shelf life | 9-12 months |

Key Features & Benefits of ZDS™ Structural Adhesive

🧲 High Bond Strength

Ideal for structural load-bearing joints

🌡️ Excellent Heat & Chemical Resistance

For extreme environments

🧪 Customizable Formulas

Tailored for your specific materials & specs

⏱️ Fast or Controlled Curing Options

UV, heat, or ambient cure types

🛡️ Impact & Vibration Resistant

Superior durability under dynamic forces

📦 Various Packaging Options

Tubes, syringes, dual cartridges, bulk drums

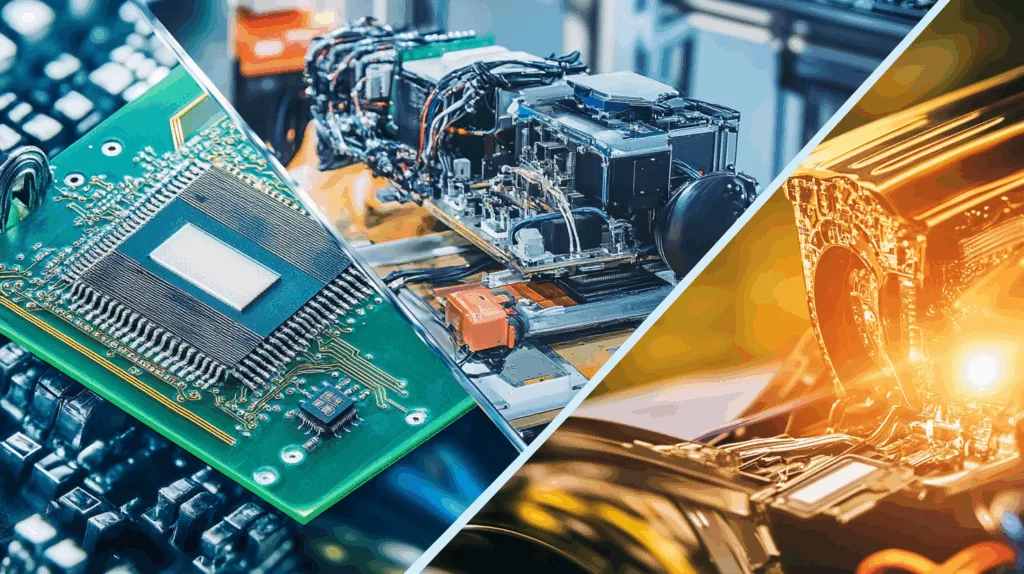

Application Fields

- Electronics Assembly

- Automotive Manufacturing

- Aerospace Components

- Medical Devices

- Glass & Composite Bonding

- Construction & Infrastructure

Technical Specifications

| Property | Typical Value |

| Shear Strength | 15–35 MPa |

| Tensile Strength | 20–40 MPa |

| Temperature Resistance | -50°C to 180°C |

| Viscosity | 5,000 – 100,000 cps |

| Cure Time (Room Temp) | 5 min – 24 hours |

| Appearance | Clear, Gray, Black options |

Why Choose ZDS™ as Your Structural Adhesive Partner?

- 🏭 20+ Years of Manufacturing Expertise

- 📍 Shenzhen-Based Factory

- 📈 R&D and Customization Services

- 🧾 ISO-Certified & RoHS-Compliant

- 🌎 Global OEM/ODM Supply Capability

- 🧰 Full Technical & After-Sales Support

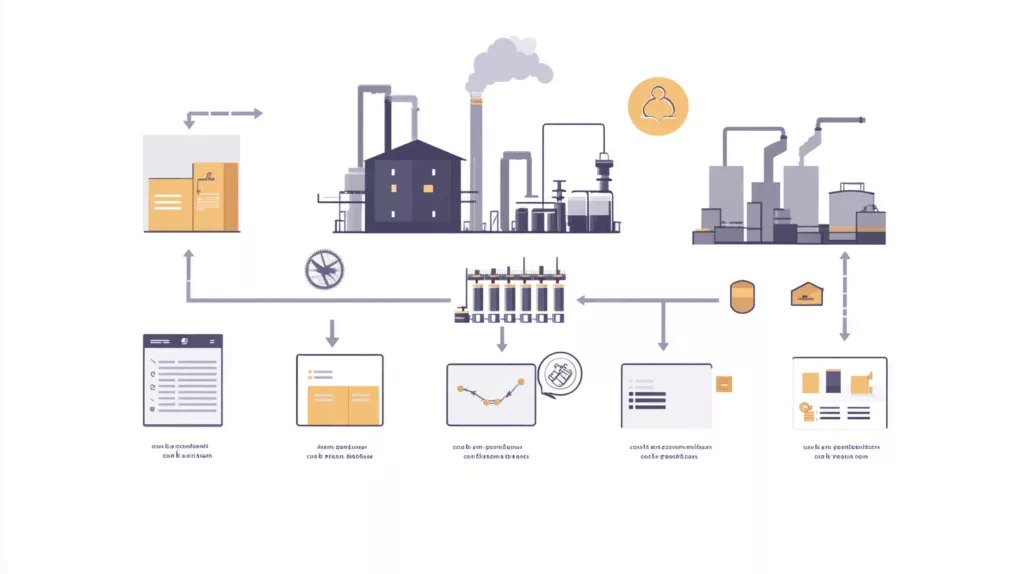

Our Adhesive Manufacturing Process

📦

Raw Material Preparation

⚖️

Precise Mixing

⚙️

Dispersion

🔬

Pre-Reaction

🧽

Filtration

💨

Vacuum Defoaming

🧴

Filling & Packaging

🧪

Quality Inspection

🚚

Delivery Worldwide

Ordering Process

- 1️⃣ Inquiry

- 2️⃣ Quotation & Sample

- 3️⃣ Order Confirmation

- 4️⃣ Production

- 5️⃣ Packaging & Delivery

- 6️⃣ After-Sales Support

FAQs

Can I get custom colors or viscosities for my structural adhesive?

Absolutely. ZDS™ offers full customization of viscosity, color, cure time, and more to match your application needs.

What’s your minimum order quantity (MOQ)?

Do you provide international shipping and documentation?

Ready to Source High-Performance Structural Adhesive?

💡 Contact ZDS™ to Get a Free Sample or Quotation Today

🔹 Reliable OEM Structural Adhesive Manufacturer

🔹 Fast Lead Time | Global Supply | Full Customization