Unlocking Next-Level Reliability: Adhesive Solutions for Renewable Energy (Solar, EV, Wind)

Modern energy systems demand more than simple assembly. Solar, electric vehicles (EV), and wind power sectors require adhesives that can withstand extreme temperatures, resist weathering, and support heavy structural loads. Choosing the right adhesive directly impacts system life, safety, and output. Leaders like ZDS supply high-performance, durable solutions tailored for these industries.

Solar Adhesive: Securing Panels Against Heat and Weather

Solar panels are routinely exposed to sunlight, harsh winds, rain, and dust. Their adhesives must hold cells, frames, backsheets, and junction boxes together while surviving years of baking heat, freezing nights, and constant UV exposure. For solar applications, ZDS recommends highly weather-resistant chemistries such as silicone, acrylic, and toughened epoxies formulated for structural stability.

Key Properties of Solar Adhesives

- High temperature resistance (Tg up to 160°C, withstands temperature cycling)

- UV and ozone stability

- Moisture and salt spray resistance (tested to ASTM B117)

- Long open time for large-panel bonding

- Good adhesion to glass, aluminum, composite, and backsheet films

Solar Panel Assembly Applications

- Cell-to-glass lamination: Film adhesives and liquid silicone prevent delamination and maintain electrical insulation.

- Frame attachment: 2K epoxies provide strong joints for aluminum frames, resisting wind loads and vibration.

- Junction box bonding: Polyurethane and acrylic adhesives protect against water ingress and support electronic connections.

Expert Takeaway

“Long-term solar reliability starts with adhesives engineered to endure decades of heat and storm exposure.” — ZDS Technical Team

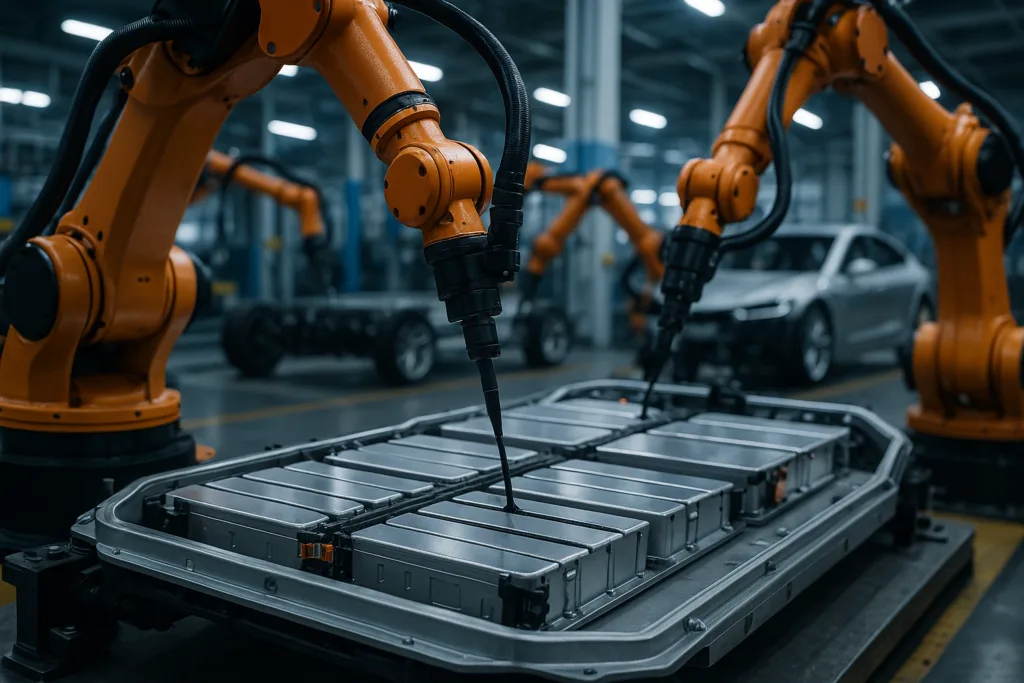

EV Adhesive: Meeting Battery, Motor, and Structural Needs

Electric vehicles place unique stress on adhesive solutions. From battery packs operating at up to 120°C, to motor housings and lightweight chassis, adhesives must meet rigorous automotive standards for heat, vibration, and chemical resistance. ZDS supplies a full range for EV battery modules, sensor assembly, and body-in-white bonding, including 1K and 2K epoxy, polyurethane, and high-performance cyanoacrylates.

Critical EV Adhesive Demands

- High temperature tolerance (up to 150°C; thermal cycling stability)

- Reliable dielectric properties (for electrical insulation)

- Dynamic shear and peel strength (ASTM D1002, D1876)

- Bonding to engineered plastics (e.g., ABS, PC, PA, PP—plasma or primer pretreated)

- Salt, oil, and coolant resistance

Adhesive Applications in EV Manufacturing

- Battery cell bonding: Silicone and modified epoxies provide heat dissipation and structural grip.

- Motor magnet fixing: High-flow epoxies avoid exotherm; maintain alignment under constant vibration.

- Body-in-white assembly: Structural acrylics and MS hybrid adhesives support lightweight, corrosion-resistant designs.

Manufacturing Insights

“A stable EV assembly depends on precise adhesive selection—tailored by cure time, viscosity, and substrate prep.”

Adhesive Solutions for Wind Turbines: Surviving Fatigue and Severe Weather

Wind turbines face bending, flexing, and harsh environmental exposure for years. Blades are often made from composite materials bonded with toughened epoxy or polyurethane. Adhesives also secure nacelle housings, sensors, and power electronics. Performance metrics like lap-shear strength, T-peel, and fatigue resistance matter most in these dynamic systems.

Key Challenges in Wind Energy Adhesives

- Extreme mechanical stress (fatigue, flexural cycles)

- Long-term weather resistance—moisture, wind-driven sand, and salt

- Chemical stability for coatings and encapsulation

- Low exotherm for large bonding areas; controlled viscosity (5000–100,000 cP)

Wind Turbine Adhesive Applications

- Blade bonding: Toughened epoxies with cure flexibility bind composite shells and internal spars.

- Nacelle assembly: Elastic polyurethanes absorb vibration and temperature changes.

- Sensor sealing: Silicone adhesives provide weatherproof and electrically insulating seals.

Comparing Adhesive Types for Energy Applications

| Chemistry | Substrates | Key Properties | Best Uses |

|---|---|---|---|

| Epoxy (1K/2K) | Metal, glass, composites | High strength, heat resistance (Lap-shear ≥ 20 MPa) |

Solar frames, EV motors, wind blades |

| Silicone | Glass, plastics, circuit boards | Flexibility, UV/weather proof (Service -50 to 200°C) |

Solar cells, EV sensors, wind nacelles |

| Acrylic | Metals, some plastics | Fast cure, moderate strength (Tensile up to 12 MPa) |

Body-in-white, solar frames |

| Polyurethane | Composites, plastics | Elasticity, chemical resistance (Elongation up to 400%) |

Wind blades, motor housings |

| Cyanoacrylate | Plastics, metals, ceramics | Fast bonding, rigid (Shore D 50–70) |

Sensor fixing, quick assembly |

Substrate Preparation and Quality Control

Adhesive strength depends on how clean and treated the surface is. Energy products use metals (aluminum, steel), glass, composites, and engineer plastics like ABS, PC, PA, and PP. For best results, degreasing and abrasion remove contaminants. Grit-blasting and priming, especially for plastics, increase bond strength. ZDS advocates thorough surface prep and adhesion promoter use for maximum durability.

Process Steps for Reliable Bonding

- Clean with solvent, then degrease

- Light abrasion for surface roughness

- Use plasma, corona, or primer for tough plastics

- Automation: bead, roll-coat, spray for consistency

- Fixture and clamp during cure to maintain alignment

Testing and Compliance

- Lap-shear and T-peel strength certification (ASTM D1002, D1876)

- Salt spray aging (ASTM B117)

- Thermal cycling and environmental stress tests

- REACH/RoHS/VOC documentation and traceability

Processing Technologies for Energy Adhesives

Automation improves quality and output. Renewable energy manufacturers use bead, slot-die, roll-coat, notched-trowel, and spray dispensing depending on part geometry and adhesive type. Mixing ratios matter for 2K (two-component) systems—static mixers ensure even blends and fast cure. ZDS offers adhesives compatible with automated lines for large-scale panel, EV, and turbine blade production.

Controlling Cure Profiles

- Pot life: How long after mixing adhesive remains usable (10 min to hours for big assemblies).

- Open time: Time before initial set allows positioning of large components.

- Heat/UV/moisture cure: Options for fast cycle or delayed assembly.

Long-Term Stability: High Temperature and Weathering Resistance

The harshest stress tests shape adhesive selection in solar, EV, and wind. High glass transition temperatures (Tg), strong moisture seals, and resistance to UV and ozone are critical. For instance, solar panel adhesives must survive 85°C humidity tests and 1,000+ hours of thermal cycling without losing bond. EV adhesives face rapid charging heating and vibration. Wind turbine adhesives endure both wild swings and relentless fatigue. ZDS engineers formulations tested for well beyond standard industry cycles.

Metrics to Monitor

- Heat age (Tg, loss of shear strength)

- UV exposure impact (yellowing, brittleness)

- Salt and humidity ingress

- Fatigue resistance (cycles to failure)

Adhesive Solutions for Renewable Energy (Solar, EV, Wind)

Renewable energy products challenge adhesives with every design advance. Solar panel makers need high-Tg silicone and acrylic for panels and junction boxes. EV manufacturers rely on grades tailored for battery packs, lightweight chassis, and high-speed motors. Wind turbine builders must bond composites and seal electronics able to withstand decades of storms and mechanical loads. ZDS offers a complete portfolio for solar, EV, and wind—tested to global standards, manufactured for consistent performance, and ready for integration into modern energy systems.

Why Choose High-Performance Adhesives?

- Stability through heat, cold, and weather

- Mechanical strength for wind, vibration, and weight

- Safe insulation for sensitive electronics

- Scalable options for automated production lines

- Compliant with environmental and safety regulations

Getting Started: Sourcing the Right Adhesive

Success in renewable energy means matching chemistry to job. Determine your substrates, stresses, and cure process. Assess compliance documentation. Request performance test data. ZDS technical teams stand ready to recommend, sample, and document adhesives suited for solar, EV, and wind energy innovation worldwide.

Frequently Asked Questions

What adhesives work best for solar panel assembly?

Silicone, toughened epoxy, and acrylic adhesives provide the high temperature, UV resistance, and flexibility needed for solar panels.

How do EV adhesives handle battery pack heat?

Special epoxies and silicones with high glass transition temperatures and thermal conductivity keep battery packs stable under extreme heat.

What properties make adhesives suitable for wind turbines?

Wind turbine adhesives require fatigue resistance, weatherproofing, elasticity, and strong bonding to composite materials.

How can I ensure strong adhesive bonds in energy products?

Clean substrates, abrasive prep, use of primers, and careful cure control all ensure maximum bond strength in energy assemblies.

Which adhesive chemistries offer weather resistance?

Silicone, polyurethane, and UV-stable acrylics resist sun, moisture, ozone, and temperature swings in outdoor energy applications.

Does ZDS supply adhesives for automated production lines?

ZDS provides adhesives engineered for bead, roll-coat, spray, and static mixing systems to suit automated renewable energy manufacturing.