Understanding Industrial Adhesive Failure

Industrial adhesives make modern manufacturing possible. They bond metals, plastics, glass, stone, and composites in industries ranging from automotive and electronics to flooring and construction. But when these bonds fail, the consequences can range from minor cosmetic issues to catastrophic structural breakdowns. Recognizing the causes of adhesive failure is the first step to ensuring product quality and safety.

What is Industrial Adhesive Failure?

Industrial adhesive failure occurs when a bond does not perform to its intended strength or durability. This can mean visible separation, reduced strength, or even sudden breakage. These failures can disrupt production, raise costs, and pose safety risks. By understanding the different types of failures and their origins, manufacturers can prevent costly downtime.

The Science Behind Adhesive Bonding

A strong bond forms when adhesive chemistry matches the substrates and processing environment. Bonds are influenced by the adhesive’s open time (how long it remains workable), cure mechanism (such as heat or moisture), application method, and more. Selecting the right adhesive is only one piece; proper preparation and process control are equally crucial.

Adhesive Chemistries and Their Properties

| Chemistry | Cure Type | Best Substrates | Key Properties | Common Applications |

|---|---|---|---|---|

| Epoxy (1K/2K) | Heat/RT | Metal, composites | High strength, rigid, chemical resistant | Automotive, electronics assembly |

| Polyurethane (PU) | Moisture/2K | Plastics, stone, metal | Flexible, impact/temperature resistant | Flooring, construction |

| Acrylic | 2K/light | Metal, glass, plastics | Fast cure, strong, UV stable | Signage, industrial assembly |

| Silicone | Moisture/heat | Glass, ceramics, metals | Flexible, UV/temperature resistant | Electronics, construction sealing |

| Cyanoacrylate (CA) | Moisture | Plastics, rubber, metals | Instant bond, rigid | Quick repairs, small components |

| Tape/Film | Pressure sensitive | Plastics, metal, glass | No cure, clean application | Electronics, automotive trim |

Essential Steps in Bonding

- Select the right adhesive and substrate combination.

- Prepare surfaces correctly, including cleaning and abrading when needed.

- Control temperature, humidity, and application method.

- Observe proper fixturing and curing protocols.

- Verify bond strength with standard tests such as ASTM D1002 and ASTM D1876.

Common Causes of Industrial Adhesive Failure

Even the most advanced adhesive technologies can stumble if process basics fall short. Let’s examine typical bonding issues and how to address each.

Poor Surface Preparation

Contaminated or smooth surfaces are among the most common culprits. Oils, dust, and release agents create barriers between the adhesive and substrate, causing premature bond failure. Glossy or non-porous surfaces (like PP or PE) resist wetting, leading to weak adhesion.

- Solution: Always degrease surfaces with isopropyl alcohol or acetone. Abrade or grit-blast metals and plastics as needed. On low-energy plastics, use corona, plasma, or apply an adhesion promoter.

Incorrect Mix Ratios and Application Amounts

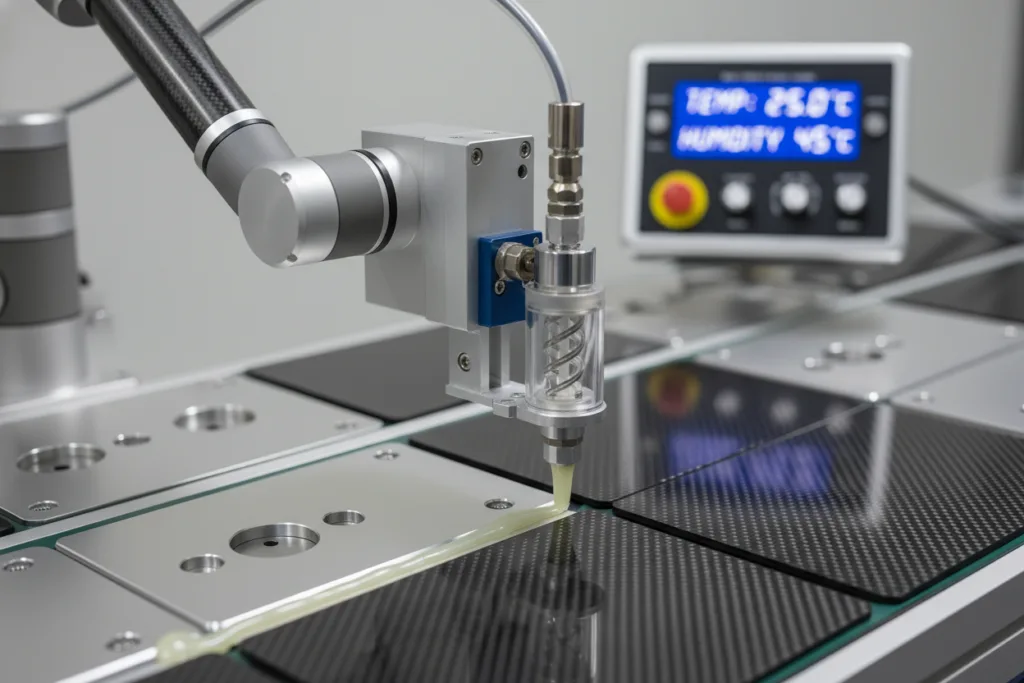

Many adhesives—especially 2K epoxies and polyurethanes—require precise mixing to cure properly. Using too little or too much adhesive affects bond strength, cure speed, and durability. Voids and air bubbles can form if mixing is inconsistent or if the bead is too thin or thick.

- Solution: Measure resin and hardener accurately. Automate dosing with static mixers where possible. Apply adhesives evenly, using slot-die, bead, or roll methods for consistent coverage. Remove air by degassing when needed.

Uncontrolled Environmental Factors: Temperature and Humidity

Temperature and humidity play a significant role in adhesive curing and final bond performance. Inadequate conditions slow or prevent cure altogether, leaving weak or tacky joints.

- Solution: Always cure adhesives within their specified temperature and relative humidity range. Use environmental chambers if needed for precision. Store products in climate-controlled facilities with clear batch traceability.

Types of Adhesive Failure

Adhesive failure isn’t always visible at a glance. Knowing the failure type helps pinpoint root causes:

- Adhesive (Interface) Failure: Bond separates cleanly from the substrate, revealing surface contamination or poor wetting.

- Cohesive Failure: The adhesive itself splits, often due to under-curing, low film build, or wrong chemistry selection.

- Substrate Failure: The bonded material fails before the adhesive, showing exceptional adhesive strength but highlighting weak substrates.

- Environmental Failure: Bonds degrade over time due to heat, chemicals, or UV—usually detected through accelerated aging or salt spray tests, like ASTM B117.

Diagnosing Adhesive Bond Issues

Use standardized tests and visual inspection to identify failure modes:

- Lap-Shear Test (ASTM D1002): Measures joint shear strength and distinguishes adhesive from cohesive failure.

- T-Peel Test (ASTM D1876): Assesses flexibility and bond strength across peel dimensions.

- Cross-section Inspection: Reveals interface integrity via microscopy.

- Accelerated Aging: Predicts long-term durability under stress.

Industrial Adhesive Failure: Prevention Methods

Now, let’s put knowledge into practice. Robust production protocols and quality checks keep adhesive failures at bay.

Implement Rigorous Surface Preparation

- Clean and degrease all surfaces—no exceptions.

- Roughen or abrade metals and hard plastics for better mechanical lock.

- Use specialty primers or surface activators for hard-to-bond substrates.

- Check for remaining residues with a water break test or portable surface energy testers.

Control Application Processes

- Mixer calibration: Train staff to verify static and dynamic mixers for ratio accuracy.

- Use automated dispensers or positive displacement pumps for high-volume lines.

- Apply adhesives within specified pot life (open time) and adjust for environmental changes.

- Visually inspect bead or film thickness—thin for fast cure, thick for heavy-duty joints.

Monitor Environmental and Curing Parameters

- Ensure temperature is within recommended range (e.g., 18–25°C for many 2K systems).

- Maintain relative humidity as specified (some silicones and CAs need 40–60% RH).

- Allow full cure before loading joints—use force testing if possible.

- Deploy data loggers for sensitive assemblies; keep pass/fail records by batch.

Process Control, Quality Checks, and Traceability

Sharpening quality control means catching issues long before finished products leave the line. Use statistical process control to spot batch-to-batch variations. Test adhesives and joints before and after environmental exposure. For regulated industries, adhere to standards like REACH, RoHS, and ISO 9001. Document all material lots, cure cycles, and test results.

Expert Insight: “Even the best adhesive can’t fix poor surface prep or incorrect process. Diligent prep, precise dosing, and a validated environment are the backbone of dependable bonding.”

The Role of ZDS in Industrial Adhesive Solutions

ZDS develops structural and non-structural adhesives tailored for demanding applications. With a deep bench of epoxies, polyurethanes, acrylics, silicones, cyanoacrylates, hybrid MS, and tape systems, ZDS helps adhesive manufacturers design, qualify, and scale robust bonding solutions. Customers benefit from hands-on support in surface prep, automation, and rigorous QC—keeping yield high and failures low.

Industrial Adhesive Failure: Trends and Best Practices

The industry continues to advance, with smarter automation, cleaner chemistries, and enhanced traceability. Hybrid systems offer better durability under thermal cycling and vibration. Modern facilities rely on automated dispensing and in-line vision checks. Still, the fundamentals of surface prep, controlled application, and environmental awareness remain unchanged. Investing in operator training, predictive maintenance, and process audits gives the best chance to prevent adhesive-related defects.

Common Industrial Adhesive Failures & How to Avoid Them

To recap, most industrial adhesive failures stem from a handful of root causes: poor surface cleanliness, uncontrolled climate, incorrect ratios, and insufficient cure. The best defense is a rigorous process supported by test-based validation and active troubleshooting. Use chemistry suited for the application, follow precise prep and cure steps, and routinely monitor key variables. Leverage partners like ZDS for advanced adhesives and technical advice. Investing in these foundations helps prevent costly rework and field failures—preserving both your product reputation and bottom line.

Frequently Asked Questions

What is the most common cause of industrial adhesive failure?

Poor surface preparation is the most common cause. Failing to clean, abrade, or properly treat substrates creates weak bonds that can separate under load.

How does humidity affect adhesive bonding?

High or low humidity can slow or prevent the adhesive from curing properly. This leads to weak joints, especially for moisture-cure and cyanoacrylate adhesives.

Can adhesives bond low-energy plastics without treatment?

Most adhesives struggle on materials like polyethylene or polypropylene unless the surface is primed, corona- or plasma-treated, or a specialty adhesive is used.

How can mixing errors be avoided in 2K adhesives?

Use precision mixing equipment, static mixers, and follow exact ratios. Train operators to recognize incomplete mixing and test viscosity or color uniformity.

What tests determine adhesive joint quality?

Lap-shear and T-peel tests measure joint strength; cross-section microscopy and accelerated aging tests reveal bond integrity and durability.

Why partner with a full-scope provider like ZDS?

ZDS offers a broad range of chemistries, technical support, and testing. This ensures adhesive selection, process, and QC are expertly matched to your needs.