Understanding Metal-to-Metal Bonding Challenges

Bonding metal to metal is tougher than it seems. Metals have smooth surfaces, low porosity, and often come with oily residues or oxide layers. These factors make it hard for adhesives to stick and transfer loads without coming apart.

Engineers demand joining methods that stand up to vibrations, temperature swings, and corrosive environments. Traditional mechanical fasteners can weaken the metal, create stress points, and add weight. Welding works for many jobs, but it risks thermal distortion and isn’t fit for mixed metals or heat-sensitive components. In most modern industries, high-performance adhesives are the solution for tough metal bonding needs.

- Automotive and aerospace parts

- Electronics chassis and shields

- Industrial enclosures and machinery

- Architectural panels and metalwork

“Selecting the best adhesive for metal to metal bonding comes down to balancing bond strength, durability, process speed, and compatibility with your substrate.”

What is the Best Adhesive for Metal to Metal?

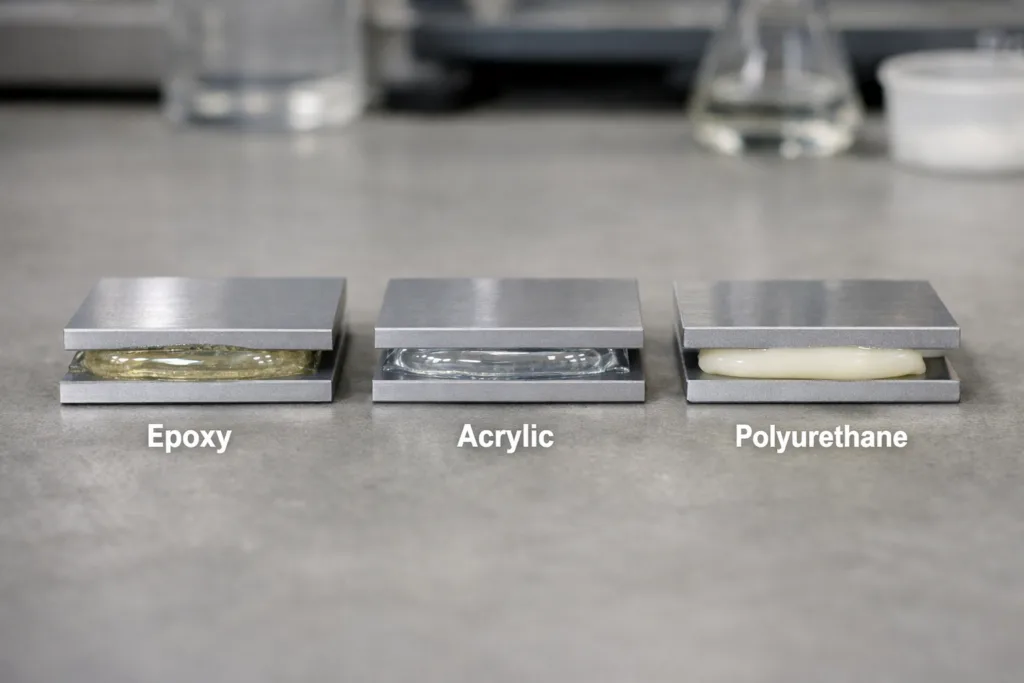

The phrase best adhesive for metal to metal covers a wide range: epoxies, acrylics, polyurethanes, and specialty chemistries. Each type brings its own strengths, cure times, resistance properties, and handling needs. Picking the right one requires understanding the failure modes in metal bonding, like lap shear and peel stresses.

ZDS manufactures high-grade adhesives for metal bonding across industries. ZDS offers epoxies, acrylics, polyurethanes (PU), silicones, and hybrid systems, each rigorously tested for actual production conditions.

Critical Strengths: Shear vs. Peel

Adhesives bonded to metal face two main types of stress: shear and peel. Shear strength measures resistance to side-to-side force (tested by ASTM D1002 lap-shear), while peel strength measures the ability to resist forces pulling up or away (tested by ASTM D1876 T-peel).

- Lap-shear strength gauges the ability to bond two metal sheets under load. High-performance epoxies often exceed 20–35 MPa lap-shear strength.

- Peel strength matters when parts may flex, bend, or be pried apart. Some acrylics deliver peel strengths up to 10 N/mm.

Both properties are critical. Industrial designers need adhesives that resist forces from every direction, indoors and out.

Epoxy vs. Acrylic vs. Polyurethane: Chemistry Face-Off

Three families dominate metal-to-metal bonding: epoxy, acrylic, and polyurethane. Each offers unique cures, strengths, and chemical resistance.

| Chemistry | Substrate Compatibility | Lap-Shear (MPa) | Peel Strength | Cure Time | Key Properties | Best Uses |

|---|---|---|---|---|---|---|

| Epoxy (1K/2K) | All metals, composites | 20–40 | Moderate | 30 mins–24 hrs | Excellent strength, rigid, high chemical & heat resistance | Structural, load-bearing, electronics |

| Acrylic (2K, UV/RT cure) | Metals, plastics | 15–30 | High | 2–20 mins | Good peel, fast cure, flexible | Automotive, appliances, fast assembly |

| Polyurethane (PU) | Metals, plastics (primed) | 10–20 | Very high | 15 mins–8 hrs | Flexible, impact resistant, good aging | Chassis, vibration-damping, construction |

Epoxy Adhesives: The Gold Standard for Metal Bonding

Epoxy adhesives are often chosen for the toughest metal-to-metal applications. Two-part (2K) epoxies mix resin and hardener and cure at room temperature, often reaching lap-shear strengths above 30 MPa after 24 hours. Single-part (1K) epoxies cure with heat, offering strong bonds and excellent temperature and chemical resistance.

- Best for structural joining where rigid bonds and high loads are needed

- Available in various viscosities for bead, slot-die, or roll-coating processes

- Excellent for bonding steel, aluminum, copper, and other engineered metals

Epoxies need good surface prep: degreasing, abrasion, and sometimes grit-blasting. ZDS epoxies are qualified against demanding QC standards like salt spray ASTM B117 and thermal cycle tests.

Acrylic Adhesives: Fast, Flexible Metal Bonding

Acrylic adhesives, often in two-part (2K) formulations, cure quickly and bond metals even with less-than-perfect surface prep. These adhesives work well for parts that flex or experience impact, delivering peel strengths up to 10 N/mm. UV-curing acrylics are available for automatic assembly lines, curing in seconds with exposure. Fast open times (2–5 minutes) enable high-throughput joins.

- Good for rapid assembly processes in automotive or appliance manufacture

- Excellent peel resistance for flexing parts

- Often used to bond aluminum, coated steel, and hybrid components

Modern acrylics tolerate light oils and oxides, reducing prep needs. ZDS acrylics meet VOC limits and ISO 9001 standards for industrial use.

Polyurethane Adhesives: Flexible and Impact-Resistant Metal Bonds

Polyurethane (PU) adhesives shine when flexibility and impact strength matter. These bonds absorb vibration and thermal expansion, making them ideal for chassis parts, construction panels, and assemblies exposed to movement. Pot life ranges from 15 minutes for fast jobs to several hours for complex assembly. PUs reach lap-shear strengths of 10–20 MPa, with very high peel resistance.

- Superior for bonding metals to flexible substrates or where movement occurs

- Ideal for construction, industrial assembly, and vibration-damping

- Compatible with primed surfaces, painted metals, and even engineered plastics with adhesion promoter

ZDS PU adhesives are formulated to support easy dispensing—slot-die, bead, or spray—and often meet REACH and VOC safety compliance.

Industrial Selection Tips: How to Find the Best Adhesive for Metal to Metal

Choosing the best adhesive for metal to metal bonding isn’t just about maximum strength. Consider your assembly process, environmental exposure, and the specific metal types. Here’s how to make your decision smarter:

- Identify Stress Modes: Will the joint mostly face shear, peel, or a mix? Structure design and failure testing should guide the choice.

- Check Cure Profile: Fast vs. slow cure, pot life, and open time matter for automated or manual processes.

- Assess Environmental Resistance: Temperature extremes, moisture, chemicals, and UV must factor in. Epoxies excel at heat and chemicals; PUs resist impact and vibration.

- Review Surface Prep Needs: Clean, roughened metals bond best; some acrylics are tolerant of poor prep.

- Test on Actual Substrates: Sheet aluminum behaves differently than stainless steel. Always run proof-of-concept bonding trials.

Consult your adhesive supplier for technical data sheets (TDS) and safety data sheets (SDS). ZDS offers lot traceability and samples for real-world testing.

Process and Application Insights from ZDS

At ZDS, adhesives are engineered for production reliability. Typical process guidance for metal-to-metal bonding:

- Metals should be degreased with solvents or alkaline cleaners

- Abrade with fine grit (120–180), sandblast, or use chemical etching to increase surface area

- Apply primer or adhesion promoter for difficult substrates (e.g., powder-coated or oily metals)

- Dispense adhesive using static mixer for 2K systems; ensure proper mix ratio

- Fixtures or clamps should hold joints for the initial cure period (often 10–60 minutes for acrylics, longer for epoxies)

- Full mechanical properties develop after 24 hours or post-cure at elevated temperature (for 1K epoxies)

ZDS supports industrial partners with full technical documentation, batch test certificates, and process optimization.

Quality Control, Compliance, and Documentation

Industrial metal bonding uses rigorous testing:

- ASTM D1002 lap-shear strength

- ASTM D1876 T-peel strength

- ASTM B117 salt spray

- Thermal cycling from -40°C to +120°C

- VOC limits, REACH, RoHS, and ISO 9001 certifications

- SDS and lot traceability for every batch

ZDS adhesives meet global standards and provide documentation for compliance, exports, and on-site audits.

Frequently Asked Questions

What is the strongest adhesive for metal to metal bonding?

High-performance two-part epoxies typically deliver the highest lap-shear strengths, often exceeding 30 MPa for steel and aluminum.

Do I need to sand or clean metal surfaces before using adhesive?

Yes, degreasing and abrasion are recommended to remove oils and oxides for optimal adhesive bonding and durability.

How fast can I assemble with acrylic metal adhesives?

Acrylics cure rapidly, with open times as quick as 2–5 minutes, making them ideal for high-volume assembly lines.

Are adhesives reliable for structural metal joining?

Modern industrial adhesives such as epoxies and acrylics are engineered for structural and load-bearing metal joints, passing rigorous QC tests.

Can I bond painted or coated metals?

Yes, with proper surface prep and suitable primer, many adhesives can bond painted, coated, or powder-coated metals securely.

Will adhesive bonds survive outdoor exposure?

Adhesives with good UV and moisture resistance, such as industrial epoxies and PUs, perform well outdoors when applied correctly.