Understanding Epoxy Yellowing and UV Resistance

Epoxy is prized for its clarity, strength, and versatility, but even the best formulations can fall victim to an unappealing transformation: yellowing. Why does epoxy turn yellow—and how does UV resistance come into play in preserving its color and clarity over time? In this article, we’ll dig into the chemical roots of yellowing, the influence of sunlight, and the latest industrial approaches to keeping epoxy looking its best—starting with the basics and building toward practical advice for manufacturers, hobbyists, and engineers alike.

What Causes Epoxy to Turn Yellow?

Epoxy yellowing results primarily from photo-oxidation triggered by exposure to ultraviolet (UV) radiation. UV rays break down the chemical bonds in the resin, leading to color changes. Heat, oxygen, and humidity also accelerate this process.

The Role of UV Radiation in Epoxy Degradation

UV light, particularly UVB and UVA wavelengths, penetrates the surface of cured epoxy and alters certain chemical groups within the resin. This often leads to visible yellowing, especially in clear or light-colored applications like flooring, countertops, and electronics potting.

Physical and Chemical Mechanisms Behind Yellowing

- Photo-oxidation: Oxygen and UV light interact with the epoxy matrix, breaking chemical bonds.

- Thermal degradation: Heat can catalyze reactions that darken the resin.

- Environmental exposure: Humidity, pollution, and surface contaminants reinforce the breakdown process.

Types of Epoxy Resins and Their UV Resistance

Not all epoxies are alike—some are naturally more resistant to UV yellowing than others. Formulation, hardener selection, and additives all contribute to performance. For specialized industrial solutions, see epoxy adhesive products, which are engineered for color stability and strength.

Bisphenol-A vs. Bisphenol-F Epoxies

| Resin Type | UV Resistance | Common Usage |

|---|---|---|

| Bisphenol-A | Poor to moderate | General coatings, adhesives |

| Bisphenol-F | Good (improved clarity) | High-performance electronics, marine |

Aliphatic vs. Aromatic Hardeners

Aliphatic hardeners generally impart better UV stability than aromatic hardeners. This is crucial for outdoor or exposed installations.

Impact of Additives and Modifiers

Chemical UV absorbers (benzotriazoles, hindered amine light stabilizers) and nano-fillers are commonly added to industrial epoxies to minimize yellowing. These additives interrupt the oxidation process and absorb UV energy before it can degrade the resin.

Evaluating Epoxy UV Performance: Testing and Standards

Manufacturers often reference international standards for color retention:

- ASTM G154: Accelerated UV aging

- ASTM D2244: Measurement of yellowing (YI)

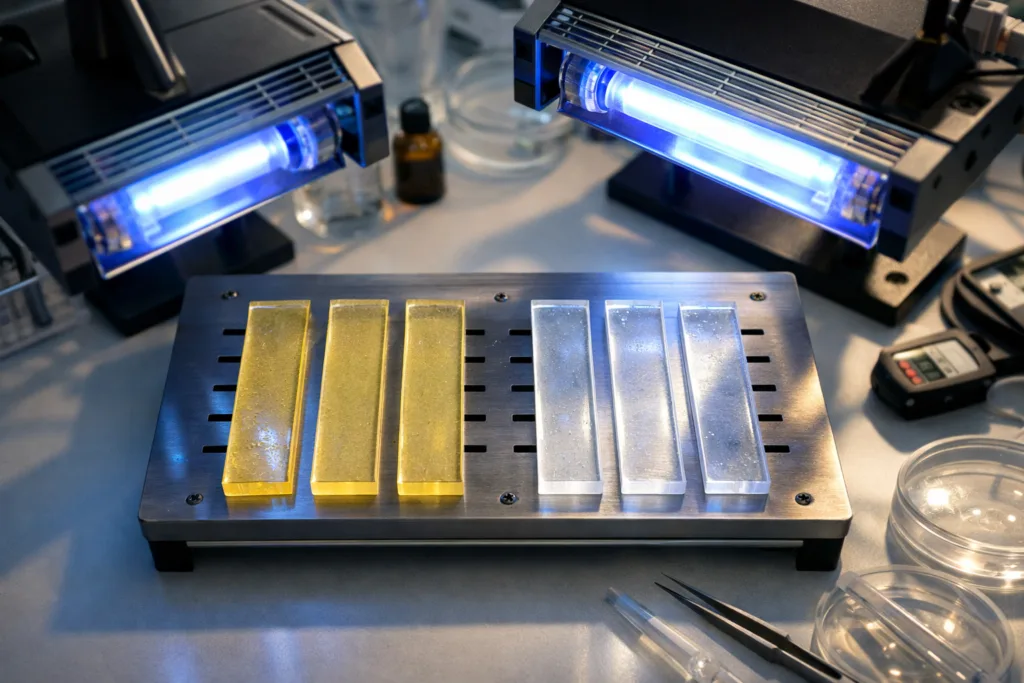

Typical tests use xenon-arc or fluorescent UV lamps to simulate months or years of sunlight exposure in a matter of days.

Industrial Benchmarks for Color Retention

Long-term clarity is prized in electronics potting and marine applications. ZDS Adhesive, an industrial adhesive manufacturer, routinely checks bond-line appearance against both physical tests (lap shear, peel) and visual metrics (color index) under real production conditions.

How to Select Epoxy for Minimal Yellowing

If color retention matters for your project, use these selection tips:

- Choose epoxies labeled “UV-resistant” or “non-yellowing”

- Prefer Bisphenol-F or cycloaliphatic formulations

- Verify data sheets for UV stability, referencing accelerated aging results

- Confirm compatibility with substrates and application method

Refer to industrial adhesives for detailed specs and suitability across industries.

Practical Application Considerations

- Outdoor installations: Apply a UV-blocking topcoat

- Marine, electronics, and automotive: Use tested products with proven field history

- Flooring and countertops: Seek formulations with additional stabilizers

Additives and Treatments to Boost UV Durability

Modern epoxies often include photo-stabilizing additives like hindered amine light stabilizers (HALS) and nanoparticle UV absorbers. These extend service life and reduce loss of transparency. For alternative protective measures, see polyurethane potting glue—ideal for high-transparency electrical applications.

Top 5 Approaches to Minimize Yellowing

- Apply a UV-resistant varnish or clear coat

- Install in shaded or indoor environments when possible

- Use pigment or dye to mask mild discoloration

- Ensure the workspace is free from excessive heat and humidity during curing

- Store unused epoxy in sealed, UV-impermeable containers

Alternatives to Epoxy for Color-Sensitive Projects

Where absolute clarity and UV endurance are vital, consider other adhesives like polyurethanes or advanced UV-curing resins. Polyurethane adhesives are more flexible and typically less prone to yellowing under sunlight, while UV-curing acrylics offer ultra-fast cure and excellent stability in AR/VR lens and electronics assembly.

Silicone and Acrylic Options Compared

| Adhesive Type | UV Resistance | Best Uses |

|---|---|---|

| Silicone | Excellent | Outdoor seals, glazing |

| Polyurethane | Very good | Electronics potting, clear assembly |

| UV-curing acrylic | Outstanding | Precision optics, AR/VR devices |

Industrial Examples: Epoxy Yellowing in Real-World Use

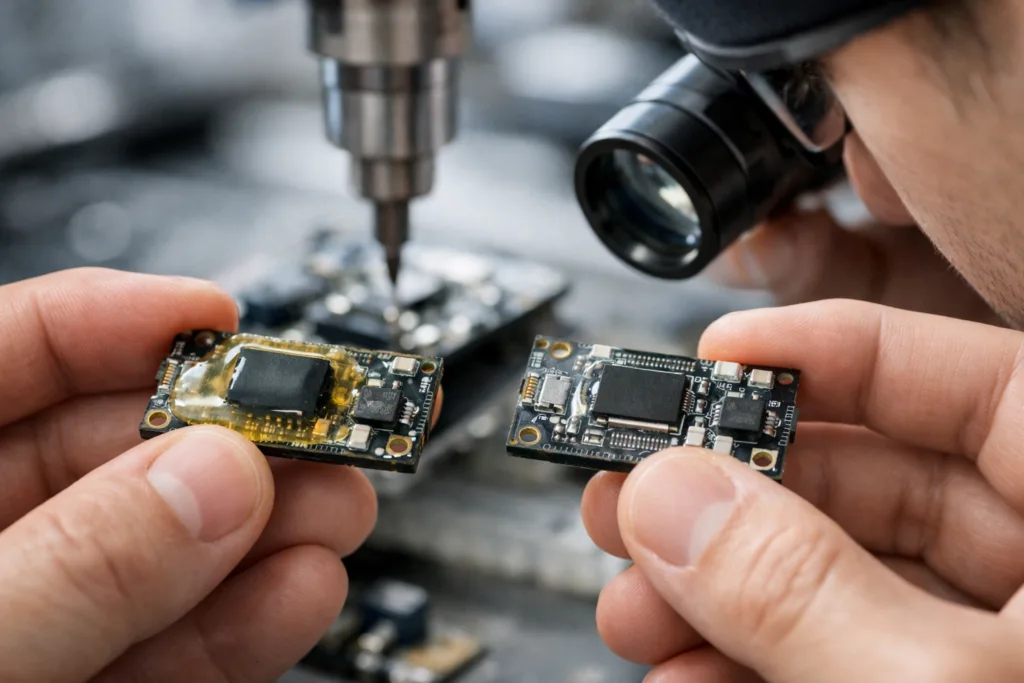

Electronics manufacturers frequently report yellowing in display cured epoxies—especially when exposed to direct sunlight through product housings. Marine repair shops often select specialty UV-stabilized products for fiberglass hull restoration, minimizing discoloration even in harsh environments. Recent advances in UV-curing adhesive technologies promise better color retention and faster processing times, as detailed in the high-transparency UV glues for AR/VR lens assembly guide.

Why Does Epoxy Turn Yellow? UV Resistance Explained

UV light destabilizes the chemical bonds in typical epoxy resins over time. Factors influencing the rate and severity of yellowing include resin choice, environmental exposure, and presence of stabilizing additives. While no solution is completely permanent, careful selection and protection measures can dramatically slow the process—even in challenging field applications.

Expert Recommendations for Long-Term Clarity

- Select cutting-edge, UV-stable industrial formulations

- Combine with UV-absorbing coatings for exposed surfaces

- Periodically inspect and replace aged or yellowed components

- Engage with manufacturers like ZDS Adhesive for application-specific guidance

Conclusion: Proactive Steps to Prevent Epoxy Yellowing

To preserve the clarity and cosmetic appeal of epoxy, understanding the chemistry of yellowing and the role of UV resistance is critical. By choosing advanced formulations, applying protective coatings, and considering environmental exposure, you can dramatically extend the service life and visual appeal of epoxy-based installations. The future holds promise—especially as new stabilizers and UV-curable adhesive systems come to market—with practical, field-tested solutions becoming more accessible for industrial and consumer use.

Frequently Asked Questions

Why does epoxy yellow even after curing?

Cured epoxy can still yellow due to continued exposure to UV light, heat, and oxygen, which slowly degrade the resin’s chemical structure.

Can additives completely prevent yellowing?

Additives such as UV absorbers and stabilizers minimize yellowing, but no solution offers absolute, indefinite protection—maintenance is key for long-term clarity.

Is outdoor use always risky for epoxy?

Outdoor exposure increases yellowing risk, but using UV-stable formulations and protective coatings can greatly reduce visible discoloration.

How can I recognize quality UV-resistant epoxy?

Check product data sheets for accelerated aging results, certifications (like ASTM G154), and references to specialized stabilizing additives for assured UV performance.

Are there clear adhesives better than epoxy for color retention?

Acrylic UV-curing adhesives and polyurethanes often outperform traditional epoxies in long-term clarity, especially under intense UV exposure.

Does tinting epoxy with pigment reduce yellowing?

Pigments can mask mild discoloration, but do not stop the underlying yellowing chemistry. Choose pigmented resin only when color stability is less critical.

Related Reading

- Toughened Epoxy Secrets: Improving Metal Bonds in Harsh Conditions

- How Gap Filler Thickness Optimizes Thermal Efficiency

- The Future of Clear UV Glues in AR/VR Lens Assembly

- Unlocking Epoxy Performance: Tg, Brittleness, and Durability Explained

- PUR Hot Melt vs. Epoxy: Which Is Best for Phone Back Covers?