Understanding Nano-Fillers: Enhancing Thermal Conductivity in Epoxies

Modern industries like electronics, automotive, and aerospace increasingly depend on efficient thermal management. One breakthrough technique that’s grabbed attention is using nano-fillers to enhance the thermal conductivity of epoxy materials—often essential in metal product assemblies and advanced composite structures. This article explores how nano-fillers work, breaks down the various types such as graphene and carbon nanotubes, and shows real-world successes from different sectors.

What Are Nano-Fillers and Why Do They Matter?

At its core, a nano-filler is a material with at least one dimension in the nanometer scale (1-100 nanometers). When dispersed into epoxy resins, they dramatically change the resin’s properties—primarily by increasing thermal conductivity without sacrificing mechanical strength or stability. The small size of nano-fillers translates to an exceptionally large surface area, allowing them to bridge heat efficiently across the epoxy matrix.

The Science Behind Thermal Conductivity in Epoxy Materials

Epoxies on their own are versatile but naturally insulating—meaning they resist the flow of heat. In metal products and electronics, this insulation can lead to overheating, component failure, or reduced operational lifespan. By integrating thermally conductive nano-fillers, the epoxy forms a network that swiftly moves heat away from critical regions, safeguarding circuits and structures. For a deep dive into how epoxy structure changes with different additives, check out the guide to industrial epoxy adhesive performance.

Types of Nano-Fillers That Power Epoxy Composites

Graphene-Based Nano-Fillers

Graphene, renowned for its remarkable conductivity and strength, is among the most efficient fillers. A single-atom-thick sheet of carbon, graphene enables continuous heat-transfer pathways at low loading levels.

Carbon Nanotubes (CNTs)

CNTs are rolled tubes of graphene. They offer a balance of high thermal conductivity and mechanical reinforcement, making them popular in composite technologies designed for metal products or electronic assemblies.

Ceramic Nano-Fillers

Substances like alumina, boron nitride, or silica add high thermal conductivity while retaining electrical insulation—a critical feature for electrical applications.

Metal Oxide Nano-Fillers

Examples include zinc oxide and aluminum oxide, which promote efficient heat spreading and also sometimes improve the chemical resistance of the cured epoxy composite.

How Nano-Fillers Transform Epoxy Material Properties

- Boosted Thermal Conductivity: Formation of heat-conducting pathways helps metal products dissipate heat rapidly.

- Maintained or Improved Mechanical Strength: Unlike macro-fillers, nano-fillers typically don’t weaken the composite matrix.

- Tailored Electrical Properties: With the right choice of nano-filler, both insulation and conductivity requirements can be balanced for safety and performance.

- Enhanced Durability: Proper nano-filler dispersion supports resilience against mechanical fatigue, thermal cycling, and chemical attack.

The Interaction Between Nano-Fillers and Metal Products

In metal product assembly, adhesives and coatings are judged by their ability to bond, protect, and manage heat. When nano-fillers are incorporated into epoxies used on metals, they help transfer heat directly into metal components, reducing hotspots and thermal stress. This synergy is crucial for maintaining component reliability in high-use environments. For more details on bonding and assembly challenges with metals, see the best adhesives for metal bonding overview.

Common Applications of Thermally Conductive Epoxy Nano-Composites

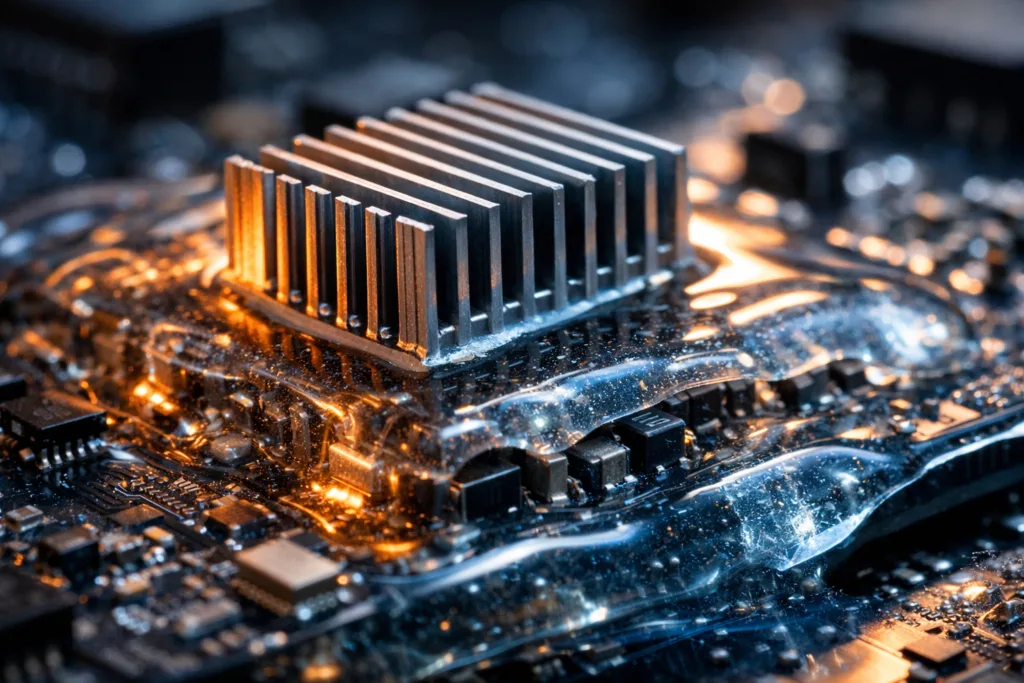

Electronics Heat Sinks and Component Potting

Efficient evacuation of heat determines the performance of chips, batteries, and sensors. Nano-filled epoxies allow for closer packing of circuitry and higher power densities without thermal runaway.

Automotive Power Modules and Battery Assemblies

Modern vehicles integrate more electronics and electrified systems. Using advanced nano-filler epoxies in battery packs and control units leads to longer component lifespans and fewer overheating incidents. For insights into thermal adhesives specifically tailored for vehicle battery cooling, refer to this selection guide for EV battery pack adhesives.

Aerospace and High-Reliability Assemblies

Demanding flight and space conditions require optimal heat transfer and strong, lightweight bonds. Nano-filled epoxies combine these performance traits in specialized aerospace connectors and sensor mounts.

Formulating Epoxy Nano-Composites: Key Process Factors

Consistent performance isn’t just about which nano-filler you pick—it’s also about how you use it. Industrial adhesive engineers at ZDS Adhesive, an industrial adhesive manufacturer, highlight some core process considerations:

- Dispersion Quality: Achieving uniform nano-filler distribution is crucial. Poor dispersion leads to uneven thermal performance and mechanical weak points.

- Filler Content & Loading: Too much nano-filler increases viscosity, making the material hard to apply. Too little results in marginal thermal improvement.

- Surface Treatment: Some nano-fillers are functionalized or coated to improve compatibility with epoxy chemistry and substrate surfaces.

- Mixing & Curing Schedules: Optimized mixing, pot life, and curing conditions maximize both heat flow and adhesive strength.

Comparison Table: Nano-Filler Types for Epoxy Thermal Conductivity

| Filler Type | Main Benefit | Drawback | Typical Loading (%) |

|---|---|---|---|

| Graphene | Top-tier thermal conductivity | Costly, tough to disperse | 0.5-2 |

| Carbon Nanotubes | High conductivity & strength | Can agglomerate, cost | 0.5-5 |

| Boron Nitride | Electrical insulation + heat transfer | More brittle composite | 5-20 |

| Alumina/Silica | Affordable, boosts hardness too | Lower max conductivity | 10-40 |

Pitfalls to Avoid When Using Nano-Fillers in Epoxies

- Poor Filler Dispersion: Clumping of nano-fillers leads to thermal inhomogeneity and weak zones.

- Incorrect Cure Profiles: Some thermal or electrical properties only develop under specific curing temperatures or schedules.

- Overloading the Matrix: Excess fillers can make application impractical and lower overall bond strength.

- Failing to Match Filler to Application: Not all nano-fillers work for every environment—electrical compatibility matters.

Case Studies: Successes of Nano-Filler Enhanced Epoxies

LED Module Thermal Potting (Electronics)

A manufacturer needed to pot high-output LEDs, where standard epoxy insulation led to overheating. By switching to a boron nitride nano-filled epoxy, junction temperatures dropped by 12°C, doubling LED lifespan and supporting denser board layouts.

EV Battery Cooling Plate Assembly (Automotive)

Electric vehicle designers face tight cooling margins in battery packs. A combination of carbon nanotube and alumina nano-fillers in the potting compound dramatically improved heat flow to aluminum cooling plates, enabling rapid charge cycles and preventing thermal runaway—a must-have for modern EVs. For a technical deep dive, study the adhesives for liquid cooling plates in EV batteries article.

Precision Avionics Module Encapsulation (Aerospace)

In a high-altitude aircraft, critical avionics modules were prone to failure due to local overheating. Implementing graphene-loaded epoxy as the encapsulant improved both heat dissipation and vibrational tolerance, extending the service life of sensitive devices.

Cost Considerations: Do Nano-Fillers Pay Off?

Adopting nano-filled epoxies sometimes means a higher upfront materials cost. However, accounting for extended component lifetime, fewer thermal failures, and reduced system-level cooling needs, most industrial users see returns in the form of lower maintenance and longer warranties. Cost-benefit varies widely by application size, volume, and performance targets.

Pushing Limits: How R&D Drives Nano-Filler Performance Advances

Ongoing research improves nanoparticle functionalization, dispersion aids, and custom filler blends. Labs have begun designing hybrid fillers that combine properties—for example, mixing boron nitride with carbon nanotubes for synergistic gains in both electrical insulation and heat transfer. Open collaboration between adhesive suppliers and OEMs is speeding up this progress and enabling highly customized solutions for specific industries.

Nano-Fillers: Enhancing Thermal Conductivity in Epoxies

Whether it’s dissipating heat in metal products, increasing resilience in confined electronics, or enabling extended battery runtimes, nano-fillers take the fundamental performance of epoxy systems to a new level. They open up new design options previously limited by thermal boundaries. Keeping up with the technology means not only choosing the right filler but implementing robust quality control and best practices at every production step.

Frequently Asked Questions

What is the main role of nano-fillers in epoxy compounds?

Nano-fillers mainly increase the thermal conductivity of epoxy compounds, enabling better heat management, especially in high-power electronics and metal assemblies.

Which industries benefit most from thermally conductive nano-epoxy composites?

Industries like electronics, automotive, and aerospace benefit the most. These sectors rely on efficient heat dissipation to extend product life and ensure safety.

Is it challenging to mix nano-fillers into an epoxy resin?

Yes, uniform dispersion is challenging due to agglomeration risk, but careful formulation using advanced mixing techniques and surface treatments increases consistency.

Can nano-filler epoxies be used for electrical insulation?

Yes—by selecting ceramic nano-fillers like boron nitride, it’s possible to achieve both improved thermal conductivity and high electrical insulation.

Do nano-fillers reduce the mechanical strength of the epoxy?

Generally, no. Most nano-fillers—when well-dispersed—either maintain or improve the epoxy’s strength and durability.

What’s a practical first step towards using nano-filler epoxies in manufacturing?

Start by defining your application’s thermal and mechanical demands, then consult with material engineers or suppliers specializing in advanced epoxy formulation.

Related Reading

- How Toughened Epoxies Improve Peel Strength & Durability

- Unlocking Epoxy Secrets: Glass Transition Temperature Explained

- Preventing Thermal Runaway: Fire Retardant Strategies for Safer Batteries

- Silicone vs. Polyurethane Potting: Which Is Right for Battery Modules?

- Epoxy vs Silicone vs Polyurethane: Choosing the Best Industrial Adhesive