Introduction: Tackling ‘Orange Peel’ Defects in Conformal Coating

Getting a flawless finish on electronics and PCBs often hinges on the details. One nagging flaw many engineers dread is the ‘orange peel’ defect in conformal coating. Named for its bumpy, uneven texture that resembles an orange’s skin, orange peel defects can undermine both aesthetic and protective functions. This article outlines how to prevent ‘orange peel’ defects in conformal coating, examining root causes like material properties, environment, and process control. We’ll share practical tips, hands-on troubleshooting, and in-line quality assurance steps to help teams achieve smooth, reliable protection every time.

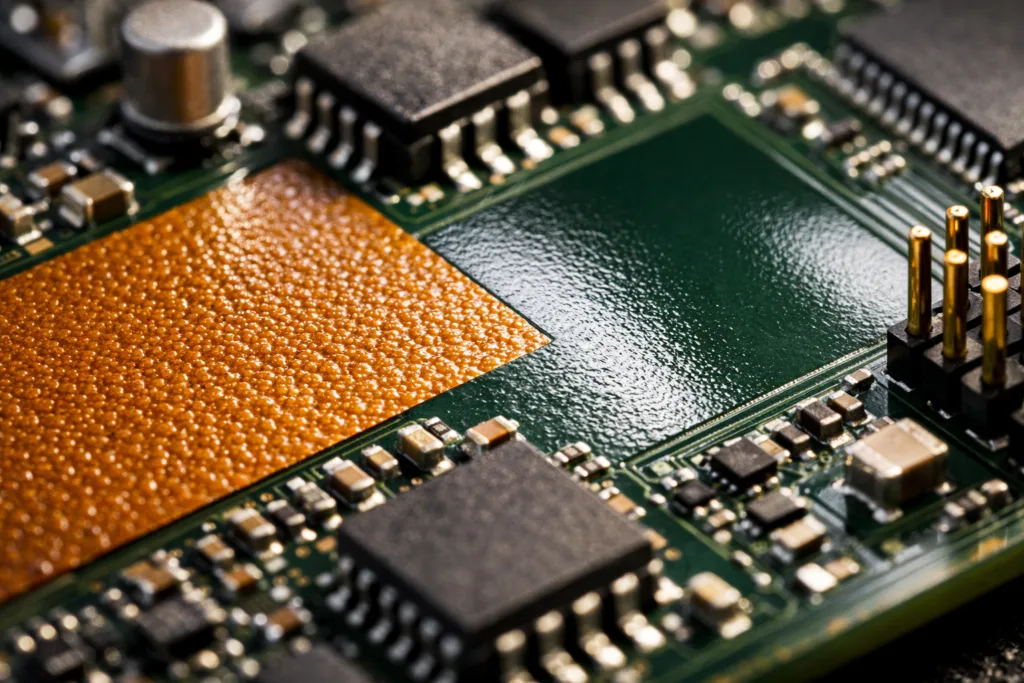

What is ‘Orange Peel’ in Conformal Coating?

‘Orange peel’ is a surface anomaly where the cured coating exhibits a pebbled, irregular texture rather than a glassy smooth finish. Instead of flowing seamlessly, the coating dries with miniature hills and valleys, affecting its protection and potentially indicating process issues. While it may not always compromise electrical insulation directly, it can signal weaknesses in the application or environment that may cause failure later.

Why Smooth Coating Matters: Risks of Orange Peel Defects

Why put in extra effort for a perfect conformal coating? The answer is reliability. Orange peel isn’t just cosmetic—it can lead to:

- Reduced dielectric performance (from trapped air pockets)

- Weakened moisture and corrosion barriers

- Inconsistent coating thickness

- Difficulties in inspection and potential rework costs

As manufacturers look for ways to maximize quality and reduce warranty risks, preventing orange peel remains a top priority on production floors.

Main Causes of ‘Orange Peel’ in Conformal Coating

Several factors contribute to orange peel defects, most boiling down to a few root causes:

- Poor surface preparation—oils, dust, or residues hamper flow

- Incorrect viscosity or improper thinning of the coating material

- Sub-optimal application technique (wrong spray gun, nozzle, pattern, or speed)

- Incompatible environmental conditions such as high humidity, low temperatures, or dust

- Premature or delayed curing, leading to uneven solvent evaporation

From hands-on line assembly experience at ZDS Adhesive, an industrial adhesive manufacturer, it’s clear that mastering these fundamentals directly reduces rework and scrapped assemblies.

Diagnosing Orange Peel Defects: What to Look For

Detecting orange peel early can save significant downstream costs. Key cues include:

- Texture visible from oblique light sources as a dimpled or mottled surface

- Patchy gloss, where high and low areas scatter light unevenly

- Consistency of the effect over several parts, suggesting systemic issues

Record defect rates and map locations to spot patterns. Compare with industry control samples when possible.

How Surface Preparation Impacts Coating Quality

Proper cleaning removes contaminants that prevent coatings from leveling out. Always start with:

- Degreasing (using IPA or approved water-based cleaners)

- Rinse and dry in dust-free environments

- Surface energy checks (dyne pens or water break tests)

Poor prep can lead to not just orange peel but also delamination and pinholing. For more details on prepping electronics for adhesives and coatings, see surface preparation techniques for adhesive strength.

Choosing the Right Conformal Coating Material

Material selection sets the limits for both reliability and processability:

- Avoid overly viscous coatings (unless intended for thick builds)

- Ensure material is within shelf life and mixed properly

- Consult data sheets for recommended spray or dip parameters

Some coatings are engineered for self-leveling and reduced tendency for orange peel, especially modern acrylics and silicones formulated for high throughput lines.

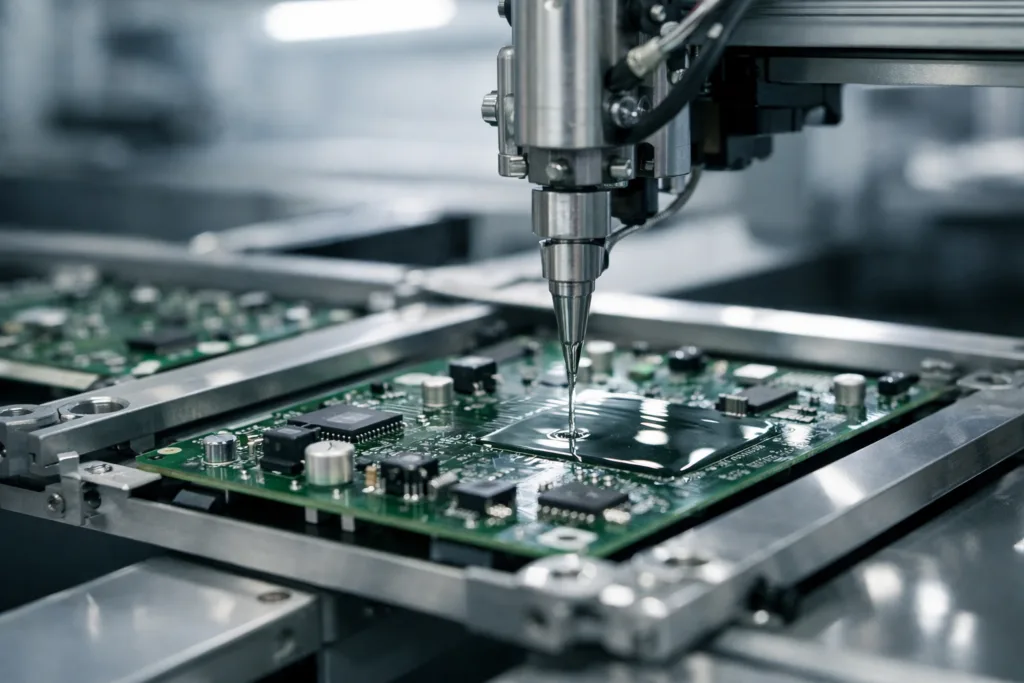

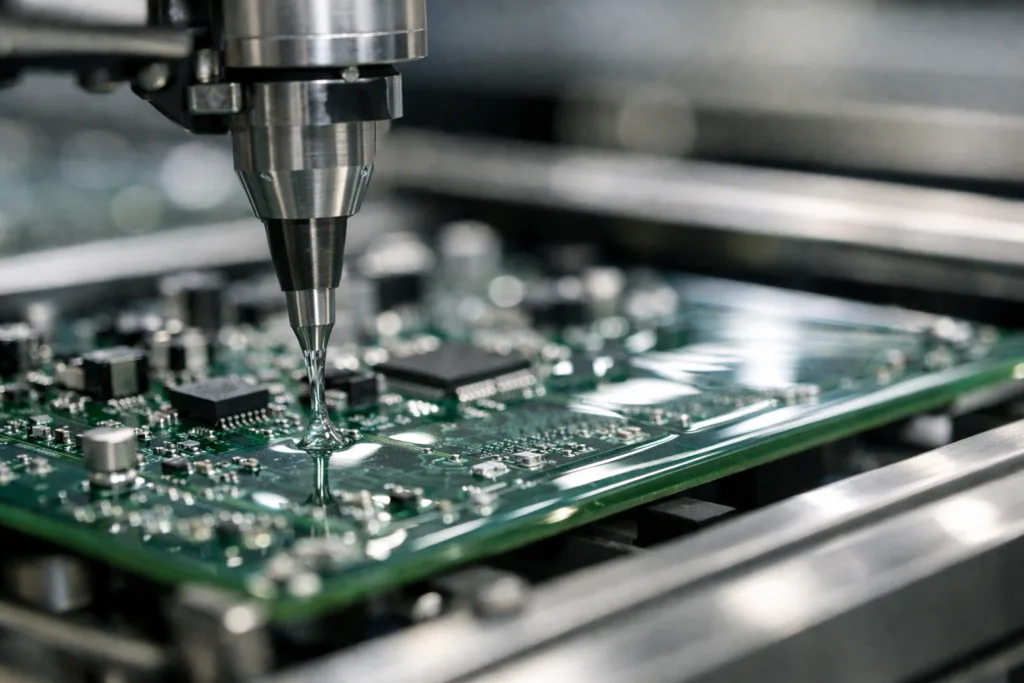

Application Methods: Spraying, Brushing, and Dipping

Different methods carry varying risks of orange peel:

- Spraying: Too much atomization, low or high air pressure, or incorrect nozzle movement increases defect risk.

- Brushing: Can leave brush marks or streaks—works best with thinner, self-leveling coatings.

- Dipping: Reduces operator errors but must control withdrawal speed and part orientation carefully.

For complex applications, it is essential to match the process to the coating and part geometry. Automated spray systems, like those found in high-volume assembly, offer consistent results but require frequent monitoring.

Environmental Factors: Temperature, Humidity, and Airflow

Controlling the environment reduces unpredictable defects:

- Temperature: Coatings flow best between 20–25°C unless otherwise specified.

- Humidity: Aim for 40–60% relative humidity. High humidity can cause condensation or slow solvent evaporation, increasing defects.

- Airflow: Excessive air movement may dry the surface too quickly, trapping solvents underneath.

Monitor conditions in real time and adjust process set points when outside ideal ranges.

Mixing and Thinning: Viscosity Management

Even with the right material, improper mixing or thinning can doom the outcome. Follow these principles:

- Always mix fully using slow, gentle agitation to minimize bubbles

- Use only approved thinners in small portions as recommended by the manufacturer

- Check viscosity with a flow cup (like a Zahn or Ford cup) and compare with the technical data sheet’s optimum range

Excessive thinning makes the coating run and separate; too much body leaves peaks and valleys—both can result in orange peel. For advanced applications requiring specific adhesive chemistry, see epoxy adhesives for electronics and optoelectronic assemblies.

Equipment Maintenance: Spray Guns, Nozzles, and Lines

Worn or clogged spray equipment is a prime culprit. Keeping your tools clean ensures even atomization. Essential tips include:

- Disassemble and clean spray guns daily

- Replace seals, gaskets, and tips at manufacturer-suggested intervals

- Flush all lines with appropriate solvents between shifts or color/material changes

It only takes one partially blocked nozzle to create orange peel on a batch of boards.

Curing and Drying Conditions: Managing Solvent Evaporation

Fast or uneven curing traps volatile compounds, leaving a bumpy surface. Best practice is to:

- Start with a short flash-off time (2–10 min) before heat or UV cure

- Avoid exceeding temperature ramp rates—no ‘shocking’ the coating

- Follow the coating’s technical bulletin for total cure time and temperature

Heat-cured and UV-cured coatings each have special requirements; know your chemistry and plan accordingly. For innovations in precision masking for selective conformal coating, see UV maskants.

Operator Technique: Building Skills to Prevent Orange Peel

Consistent training is essential:

- Maintain uniform distance (typically 10–20 cm) when spraying

- Overlap passes by at least 50% to avoid streaks and thin spots

- Practice steady, slow, parallel movements—don’t ‘snap’ your wrist at the end of a pass

Supervisors should routinely observe operators, especially when new coatings or tools are introduced.

Material Shelf Life and Storage

Expired or poorly stored coating materials can separate, thicken, or become contaminated. Always check:

- Manufacturing and expiration dates

- Container seals and storage temperatures (do not freeze or overheat)

- Material lot traceability—change in appearance or scent can hint at problems

Real-World Examples: Common Failure Scenarios

Let’s look at two recurring examples shared by process engineers:

- The plant switched to a winter delivery of coating—stored near a drafty loading dock. Viscosity shot up due to cold, and orange peel defects surged until the lot was conditioned in the assembly shop for 24 hours first.

- An experienced operator attempted to thin a high-solids silicone beyond the recommended ratio, leading to rapid solvent “pop” and coarse pebbled surfaces on several production runs.

Root cause analysis and continuous feedback help sustainable process improvements take hold.

Best Practices: A Checklist to Prevent ‘Orange Peel’

- Pre-clean all substrates and ensure no residue remains

- Verify coating viscosity and mix according to data sheet

- Use well-maintained spray/dip equipment

- Control temperature, humidity, and airflow near the coating line

- Stick to recommended cure schedules and ramp rates

- Monitor operator consistency and update training regularly

How to Prevent ‘Orange Peel’ Defects in Conformal Coating

Summarizing prevention:

- Stabilize your process parameters: Always calibrate and maintain application equipment for uniform delivery.

- Keep an eye on climate: Adjust process windows for ambient changes—install monitoring if required.

- Follow a strict material management protocol: Rotate stock, inspect, and reject questionable batches.

- Troubleshoot early: Address small flaws before scaling up production or switching to a new product/lot.

Advanced Solutions and Industry Trends

In 2026, new conformal coatings offer improved self-leveling and humidity tolerance. Automated inline vision inspection detects surface texture in real time, flagging orange peel before cure, so parts can be reprocessed or discarded immediately, minimizing waste. Surface modification, such as atmospheric plasma, raises surface energy and further supports flawless coating results on tough substrates like polyolefins and low-energy plastics.

Troubleshooting Table: Addressing Orange Peel Defects

| Cause | Symptom | Corrective Action |

|---|---|---|

| High viscosity | Thick, uneven bumps | Thin coating per data sheet |

| Poor surface cleaning | Irregular or patchy texture | Improve wash/rinse process |

| Improper spray pressure | Spotty or pitted surface | Adjust air pressure/atomization |

| Low temperature/high humidity | Rough, dimpled finish | Regulate environment |

| Fast/delayed solvent evaporation | Wrinkled or cratering | Control flash-off/air movement |

Industry Insights: ZDS Adhesive Approach to Orange Peel

From an assembly engineer’s perspective at ZDS Adhesive, careful process control and up-to-date material training are essential for orange peel prevention. For every change in substrate, load, or climate, we recommend retesting lap shear and peel resistance, as well as staging sample panel runs whenever operators spot anomalies. No single cure-all exists—vigilance at each stage delivers the best results.

Conclusion: Building Consistent Quality in Conformal Coating

How to prevent ‘orange peel’ defects in conformal coating boils down to one key point: success depends on disciplined attention to each process variable. By focusing on root causes—material integrity, equipment condition, operator training, and environment—teams can all but eliminate this defect. As coatings and inspection continue to evolve, the goal remains the same: reliable, flawless protection for every electronic assembly produced.

Frequently Asked Questions

What is the most common cause of orange peel in conformal coatings?

The most common cause is improper surface preparation or using coating material with incorrect viscosity, both of which prevent proper flow and leveling.

Can environmental conditions cause orange peel defects?

Yes, high humidity, low temperatures, and excessive dust or airflow can interfere with solvent evaporation, increasing the chance of orange peel.

Is orange peel only a cosmetic issue?

No, while it appears cosmetic, orange peel can signal uneven thickness, trapped air, or weak sections that may reduce long-term reliability.

Does thinning the conformal coating always help prevent orange peel?

Not always—excessive thinning can create other issues like runs or sagging. Always thin within the manufacturer’s recommended range.

Are automated or manual processes better for preventing orange peel?

Automated processes provide repeatability, but consistent real-time monitoring and operator skill are essential for best results in either approach.

Should I rework or scrap parts with orange peel?

It depends on the severity and function. Mild texture may be acceptable, but electrical or barrier failures require rework or scrapping.

Related Reading

- Ultimate Comparison: Conformal Coating vs. Potting Compound for PCB Protection

- Going Green: Why Low Halogen Epoxies Matter in 2026

- 13 Expert Tips for B-Stage Epoxy Applications and Storage

- Choosing the Right Adhesive for CTP Battery Manufacturing

- How Adhesives Survive Fast Charging: The Science of Thermal Shock Resistance