Introduction: Understanding Oxygen Inhibition, UV Glue, Sticky Adhesive, Curing Process

Ever wondered why your UV glue remains sticky after curing? The culprit is often oxygen inhibition—a phenomenon that disrupts the curing process of UV adhesives, particularly on exposed surfaces. Whether you’re bonding plastics, metals, or glass, sticky residues can undermine your assembly, leading to costly rework or product failures. This article explores what oxygen inhibition means for UV glues, why it happens, and how to fix it for robust and reliable bonds.

For those working on industrial and manufacturing projects, knowing the chemistry and process behind oxygen-sensitive curing is crucial. We’ll walk through practical solutions, proven strategies, and real-world examples so you can confidently tackle sticky adhesive issues, whether you’re after flawless finishes or high-performance bonds.

What Is Oxygen Inhibition?

Oxygen inhibition occurs when atmospheric oxygen interferes with the polymerization process of UV curing adhesives, resulting in a sticky, tacky, or soft surface even after exposure to UV light. This effect is especially common with free-radical UV adhesives, but less so with cationic-curing systems.

The Science Behind UV Glue Curing

UV glues cure when exposed to UV light, triggering a photoinitiator that starts a chain reaction, polymerizing the liquid adhesive into a solid. Oxygen molecules absorb free radicals during this process, preventing full cure on surface layers. The result? A sticky layer, poor bonding, and loss of clarity or finish.

Which Types of UV Adhesives Are Most Affected?

Free-radical UV adhesives—acrylate-based formulas—are highly susceptible to oxygen inhibition. Cationic UV adhesives (epoxy or vinyl ether chemistries) resist oxygen interference but cure more slowly in air.

How Oxygen Inhibition Shows Up in Production

You know oxygen inhibition is present when:

- Surface remains sticky/tacky despite proper UV exposure

- Bond strength is weak or inconsistent

- Surface finishing steps—such as painting or sealing—fail to adhere

- Visible haze or cloudy spots develop

Why Your UV Glue Stays Sticky: Surface vs. Bulk Cure

In most cases, the bulk of the adhesive underneath cures fully because oxygen cannot penetrate deep into the glue layer. The surface, however, is directly exposed to air, which means oxygen is readily available to disrupt polymerization in the top few microns.

Key Factors Affecting Oxygen Inhibition

- Type of UV adhesive (acrylate vs. cationic)

- UV wavelength and intensity

- Ambient oxygen concentration

- Adhesive film thickness

- Surface area exposed to air

Comparing Cure Depth: Free Radical vs. Cationic

| Adhesive Type | Surface Cure | Bulk Cure | Resistance to Oxygen |

|---|---|---|---|

| Free Radical | Often tacky | Strong | Poor |

| Cationic | Firm | Strong | Good |

Oxygen Inhibition: Why Your UV Glue is Sticky & How to Fix It

This section dives into solutions. Tackling oxygen inhibition means understanding why your UV glue is sticky—and picking the right fix.

Strategic Solutions: Overcoming Sticky UV Cures

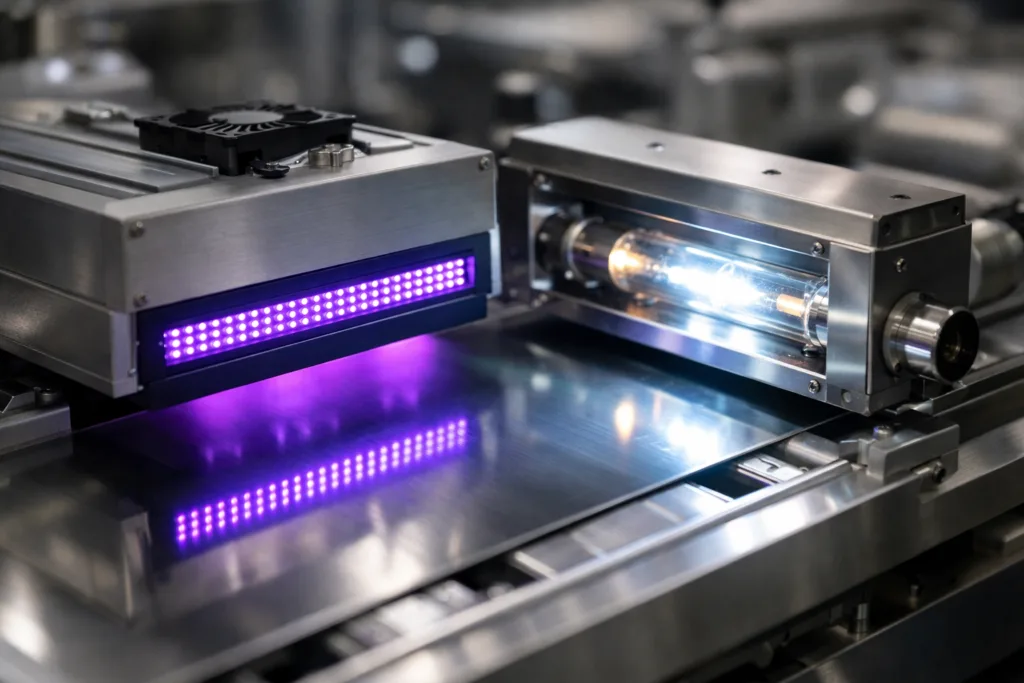

- Inerting—Using Nitrogen/CO2 Blankets: Creating a low-oxygen environment over your adhesive surface using nitrogen or carbon dioxide shields prevents oxygen from reaching the curing adhesive. This solution is common in electronics, optics, and high-value assembly lines.

- Apply Mylar or Transparent Films: Covering the adhesive with a clear plastic film during UV exposure keeps air away, allowing full surface cure. Peel the film away after curing for a hard, tack-free surface.

- Use Cure Accelerators or Initiators: Formulations with added cure accelerators counteract inhibition and enhance surface hardness. Specialized additives are widely used in the industry for this purpose.

- Switch to Cationic UV Adhesives: If oxygen inhibition is a recurring challenge, switching to cationic UV adhesives can reduce sticky surfaces but comes with longer cure cycles and moisture sensitivity.

- Layered Curing—Multiple Exposure Steps: Sometimes, a second UV exposure after initial cure improves surface hardness, especially with thin films or small parts.

Case Study: Smartphone Lens Assembly

A leading electronics manufacturer struggled with sticky UV adhesive spots in smartphone lens bonding. By switching to a high-transparency UV glue formulated with cure accelerators and using Mylar masking, tack-free finishes were achieved. Reliability increased and downstream assembly defects were eliminated—all thanks to a thoughtful approach to oxygen inhibition.

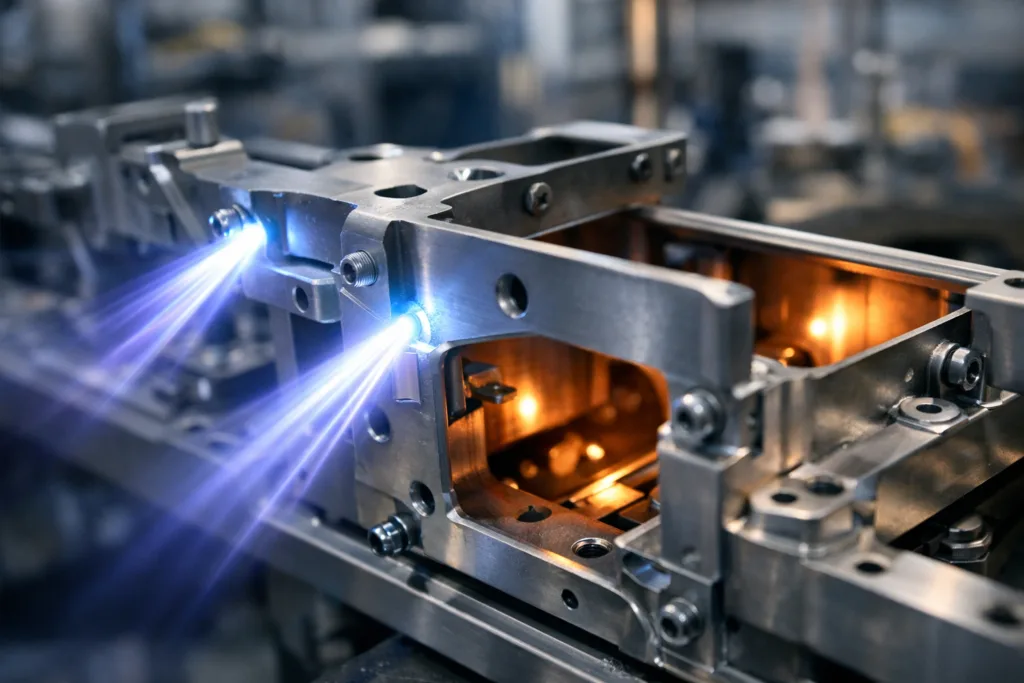

Brand Insight: Experience from ZDS Adhesive

From the application engineering team at ZDS Adhesive, an industrial adhesive manufacturer, common process improvements include nitrogen blanket curing, adjusting UV exposure time, and using adhesives with tailored oxygen resistance. For plastic assembly, the recommended approach combines surface sealing (Mylar films) and tuneable UV intensity for optimal surface cure, confirmed by lap shear and peel tests under realistic load and humidity cycles.

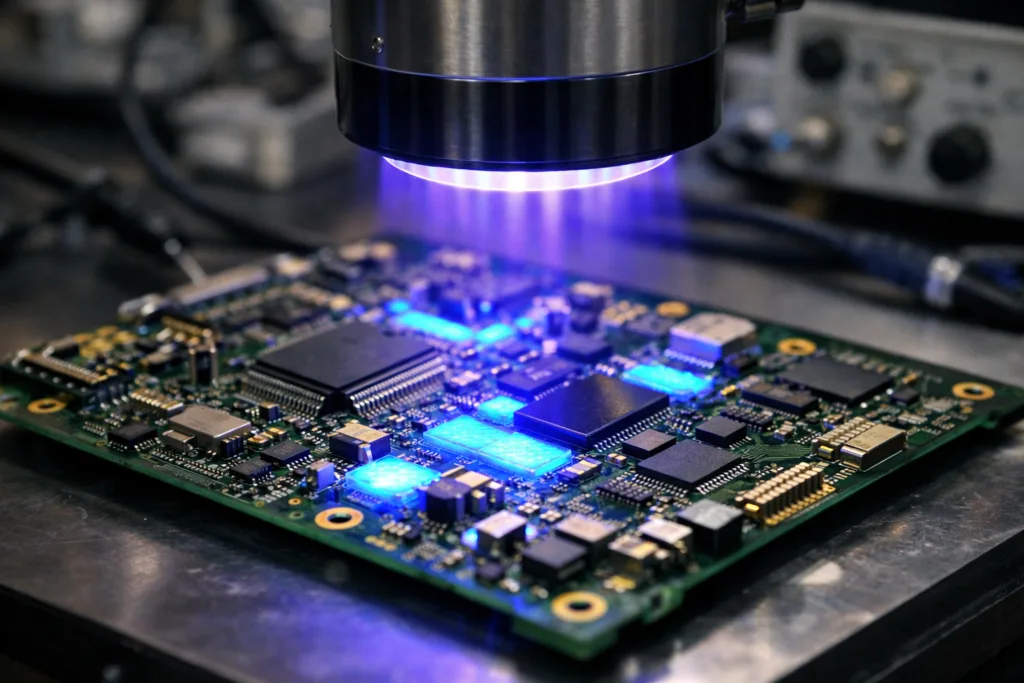

Protecting Sensitive Electronics: Oxygen Inhibition Solutions

Electronic assemblies—especially PCB encapsulation and display bonding—require flawless surfaces. Oxygen-inhibition can lead to poor electrical insulation or faulty sensor performance. Solutions include low-oxygen environments and dual-cure adhesives, as covered in this article’s related reading hub.

For example, in PCB dam-and-fill encapsulation, inerting is critical. Learn more in “How Dam and Fill Encapsulation Protects Sensitive PCB Components in 2026.”

UV Maskants and Oxygen Inhibition

UV maskants, used for selective protection or coating, are especially prone to oxygen inhibition. For these, select specialized products with improved oxygen tolerance, such as those listed on UV maskants page.

Optimizing the Curing Process: Practical Rules & Testing

The curing window for industrial UV adhesives is defined by exposure time, light intensity, wavelength, and environmental oxygen. Use this checklist to minimize inhibition:

- Confirm UV light intensity and uniformity

- Use low-oxygen environments for surface cures

- Test surface hardness via standard peel-off or pencil hardness methods

- Evaluate lap shear and peel strength (especially with plastic substrates)

- Document process parameters for each production run

Industrial Adhesives with Engineered Oxygen Resistance

Some advanced industrial adhesives are formulated specifically for oxygen inhibition resistance. Explore options for industrial adhesives that address common UV curing challenges, including sticky surface prevention.

Comparing Oxygen Inhibition Fixes: Process Stability vs. Speed

| Solution | Benefit | Drawback | Best Use Case |

|---|---|---|---|

| Nitrogen Blanketing | Maximum surface cure | Added equipment cost | High-value electronics/glass |

| Mylar Masking | Inexpensive, flexible | Film removal step | Small assemblies, batch processing |

| Accelerator Additives | Fast results | Possible odor, material compatibility | Speed-focused production |

| Cationic UV Adhesives | Consistent surface cure | Slower, moisture-sensitive | Specialty electronics, optical |

| Dual-Cure Adhesives | Solves shadow areas | Complex formulations | PCBs, connectors |

Conclusion: Mastering Sticky UV Adhesive Cures

Oxygen inhibition is the leading reason why UV glue surfaces can stay sticky after curing. By understanding the underlying chemistry and selecting appropriate process fixes—such as inerting, masking, accelerators, or advanced adhesive formulations—manufacturers and assembly teams can achieve consistent, tack-free finishes and durable bonds. With real-world examples, practical solutions, and process-specific checklists, overcoming oxygen inhibition is possible, whether in electronics, optics, or industrial applications.

Frequently Asked Questions

What causes oxygen inhibition in UV glue?

Oxygen inhibition happens when oxygen from the air absorbs free radicals during the UV curing process, preventing the adhesive from fully solidifying at the surface.

How can I fix a sticky UV glue surface?

Tactics include curing under a nitrogen blanket, applying a Mylar film, increasing UV intensity, or switching to oxygen-resistant adhesives.

Are all types of UV adhesives affected by oxygen inhibition?

Free-radical UV adhesives are most affected. Cationic UV adhesives are more resistant, but cure slower and need moisture control.

Does oxygen inhibition affect bond strength?

It mostly impacts the top surface. Bulk bond strength may be good, but surface stickiness can cause adhesion failures in finishing steps.

Do environmental conditions matter for UV curing?

Yes! Ambient oxygen, temperature, and humidity influence cure quality, especially for thin adhesive films or critical surface finishes.

Can I use additives to reduce oxygen inhibition?

Yes, cure accelerators and initiators are often incorporated into UV adhesive formulations to improve surface cure and reduce tackiness.