UV Adhesive for Electronics – Fast, Precise & Reliable Bonding

Looking for a high-performance adhesive designed for electronic component bonding? Discover ZDS™ UV adhesives – engineered for precision, speed, and reliability in electronic assemblies.

Engineered for Electronics: Why Use UV Adhesives?

ZDS UV Adhesive for Electronics

Model

Appearance

Viscosity /cps

Curing energy mj

Details

- ZDSCD2108204 Model lamp bead glue

- Transparent or yellowish liquid

- 3000~3400

- 400-800mj£»365 point light source

Need help choosing the right adhesive?

Just share your needs with us — our experts will match you with the best solution. Click the button below to get started.

Applications of UV Adhesive in Electronics

PCB Assembly

Secure components like sensors, resistors, and capacitors with pinpoint accuracy. Our adhesives maintain integrity even during soldering processes.

Wire Tacking & Reinforcement

Prevent micro-movements and reduce stress on solder joints by fixing wires, coils, and connectors in place.

Chip Encapsulation

UV adhesives are ideal for potting or encapsulating chips, safeguarding them from moisture, dust, and mechanical shock.

Lens & Display Module Bonding

Ensure crystal-clear bonding for camera lenses or display components with optically clear formulations.

Electronic Wearables

Use in smartwatches, earbuds, fitness trackers and other miniaturized electronic assemblies where precision and flexibility are key.

Key Benefits of ZDS™ UV Adhesives for Electronics

Ultra-Fast Curing

Cure in 2–5 seconds under UV/LED light, allowing for high-speed automated assembly lines.

Low Ionic Impurity

Formulated with ultra-low halogens and metals, minimizing the risk of corrosion and ensuring long-term electronic reliability.

Excellent Dielectric Properties

Acts as an electrical insulator, making it safe for use on or near circuitry.

Minimal Outgassing

Safe for enclosed spaces like camera modules or optical assemblies where fogging must be avoided.

Non-Shrinking

Maintains shape and stability post-curing—critical for precise microelectronic components.

Precision Dispensing

Compatible with micro-needle dispensing systems for highly controlled application in tight spaces.

Technical Specifications

- Cure Wavelength: 365–405 nm

- Recommended Lamp Power: 50W–200W UV LED

- Shelf Life: 6–12 months at 5–25°C

- Packaging: 30ml / 50ml / 250ml syringes or bulk containers

- RoHS/REACH Compliance: Yes

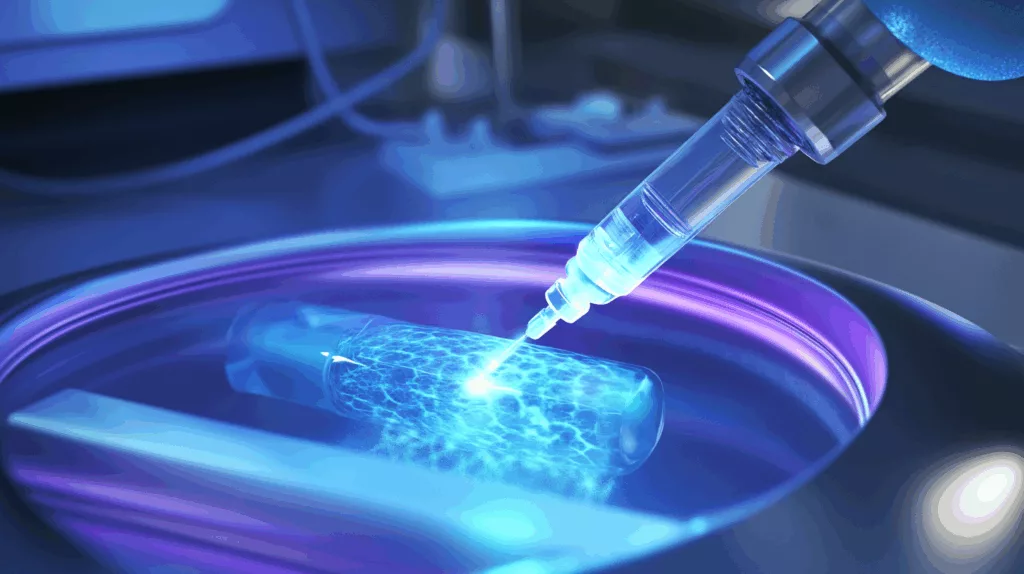

How to Apply UV Adhesive in Electronics

- Clean Substrates: Use isopropyl alcohol to remove oils, dust, and contaminants.

- Apply Adhesive: Dispense in precise amounts using an automated or manual dispenser.

- Cure: Expose the adhesive to a UV light source. Ensure full exposure to avoid uncured zones.

- Post-Cure Inspection: Verify the bond with visual or strength testing.

Who Should Use ZDS UV Adhesives?

If you are:

- An OEM electronics manufacturer

- A PCB assembler

- A contract manufacturer producing smart devices

- A prototype lab developing electronic modules

Then ZDS™ UV adhesives are the ideal solution to improve your bonding reliability and efficiency.

Frequently Asked Questions

Will UV adhesives interfere with electronic signals?

Are ZDS™ UV adhesives RoHS compliant?

What type of UV light is needed?

Can I request custom formulations?

Can I get samples for testing?

Customer Testimonials

Ready to Improve Your Electronic Bonding Process?

- Application testing

- Custom formulation

- Reliable global shipping

- Full documentation & certifications