Introduction: The Challenge of Exothermic Reaction in Large Epoxy Castings

Managing exothermic reactions is one of the biggest challenges when working with large epoxy castings. As epoxy resin and hardener mix, a chemical reaction releases heat — the so-called exotherm. In small castings, heat escapes easily, but in large volumes, dangerous heat buildup can lead to cracking, discoloration, incomplete cures, or even fire. This guide explores core principles and real-world experience for safely controlling exothermic reaction in large epoxy castings, ensuring both quality and safety for large-scale projects.

Understanding the Exothermic Reaction in Epoxy Casting

Exothermic reaction is the chemical process that produces heat during epoxy curing. When the temperature rises past a threshold, this can accelerate the reaction, creating a ‘runaway’ cycle. In large castings, the mass and thickness limit heat dissipation, causing substantial temperature spikes. Knowing how these reactions work is crucial for successful, safe projects.

What Triggers Dangerous Exotherm Events in Large Epoxy Castings?

Several factors can worsen excess heat during epoxy setups:

- Mixing large batches at once

- Pouring at excessive thickness

- Wrong mix ratios or too much hardener

- Ambient temperature above 25°C (77°F)

- Low-quality or fast-curing resin systems

It’s essential to understand how each variable impacts the heat buildup during curing.

The Science of Heat Buildup: Surface Area, Volume, and Cure Rate

The heat generated by an exothermic reaction is directly related to the volume of resin. Larger volumes mean less surface area to disperse heat, which is why thin layers can cure safely but deeper pours can overheat. Choosing the right epoxy adhesive and scheduling pours is essential for thermal management.

Mix Ratio Mistakes: How Tiny Errors Trigger Massive Heat Spikes

The resin-to-hardener ratio must be exact. Even a few extra grams of hardener can double the heat output and halve pot life. Always use calibrated scales, and never estimate by eye. Following the recommended mix ratio on your industrial adhesives is a first defense against dangerous exotherm.

Choosing the Right Epoxy System for Large Castings

Industrial adhesives designed for deep pouring have slower cure speeds and lower exothermic output. Ask suppliers for epoxy systems formulated for thick castings. These typically feature slower-reacting hardeners and special fillers to manage thermal output.

Controlling Pour Thickness: Layering for Safe Curing

One of the safest techniques is to pour epoxy in multiple thin layers (often 10–25 mm per pour). Each layer cures before the next is added, limiting runaway heat. Professional projects often require staged pouring to achieve deep castings safely.

Ambient and Substrate Temperature Control

Work only in temperature-controlled, ventilated environments. The best range is usually 18–22°C (64–72°F). If it’s hotter, the reaction accelerates. Keeping molds and substrates cool also helps draw away excess heat. Some professionals even use cooling fans or water baths for large jobs.

Clever Use of Additives and Fillers to Absorb Heat

Adding inert fillers (like silica, alumina, or glass beads) absorbs heat and slows the cure. These additives also improve physical properties in the final part. Always match your filler choice with the type of adhesive solution you need for mechanical or electrical performance.

Monitoring Exotherm: Tools and Techniques

Thermocouples or infrared temperature guns can help you monitor surface and internal temps as the reaction progresses. Tracking temperatures during production is crucial for preventing accidents and optimizing results.

Scheduling and Batch Planning: Key for Consistency

Break large projects into smaller tasks. Plan for staggered mixing and pour schedules, allowing each stage enough time to cure before proceeding. This lowers risk of thermal spikes and ensures uniformity throughout your casting.

Ventilation and Fume Management During Curing

Epoxy can release fumes as it cures, especially when exotherm is uncontrolled. Ensure proper airflow in your workspace and consider using extraction systems. Always consult Safety Data Sheets (SDS) before scaling up production or trying new materials.

Case Study: How Exothermic Reaction Surprised a Custom Table Maker

A furniture company attempted a single, deep pour for an epoxy river table. They noticed bubbling, yellowing, and cracks by dawn. Investigation revealed the room was too warm and the batch was too thick. After adjusting to thinner pours and using a slower epoxy, they achieved flawless, crystal-clear results. This underscores why controlling exothermic reaction in large epoxy castings is non-negotiable for project success.

Material Selection: Why All Epoxies Don’t Perform the Same

Selecting the right resin system for your needs is essential. Slow-cure, high-volume epoxies minimize peak exotherm temperatures and extend working time. High-performance variants may include flexible additives for shock or vibration resistance, particularly in automotive and marine applications.

The Impact of Mold Design and Thermal Conductivity

Mold material has a big effect on thermal management. Metal molds draw heat away quickly; plastic or wood molds insulate and may trap heat. Design your molds with these properties in mind to optimize heat dissipation.

Scaling Up: What Changes as Your Project Grows?

Scaling from prototype (small panels) to production (large castings) demands a rethink of curing procedures. More mass means more potential for dangerous heat spikes and less margin for error. Always validate your process at every scale stage.

Thermal Imaging for Process Control

Thermal cameras provide real-time feedback during casting, highlighting hot spots. Corrections can be made on the fly, such as cooling affected areas or pausing production. This is becoming standard in high-end manufacturing workflows.

Surface Issues: Bubbles, Blushing, and Exotherm-Related Defects

Uncontrolled heat creates cosmetic flaws like bubbles, fisheyes, or white ‘blushing’ areas. Proper control of exothermic reaction, combined with degassing practices, minimizes these risks and ensures a polished final product.

Safe Handling Practices and PPE

Personal protective equipment is a crucial part of working with large epoxy volumes. Gloves, goggles, and masks protect against splashes and fumes. Always store mixed epoxy in safe containers to prevent accidental heat buildup and fire.

Testing for Cure Completion and Mechanical Properties

Larger castings demand a longer cure and slow post-curing cycles to reach full strength. Test finished parts for hardness, flex, and chemical resistance before releasing them into real-world service.

Environmental Considerations in Epoxy Casting

Efficient thermal management also reduces emissions and waste. Selecting low-odor, low-VOC systems further protects workers and the environment. Responsible disposal of resin waste is also an essential best practice.

Insights from ZDS Adhesive: Preventing Exotherm Runaway with Material Selection

At ZDS Adhesive, an industrial adhesive manufacturer, engineers select epoxy chemistries based on maximum part thickness, pot life requirements, and thermal sensitivity of embedded parts. Their guidelines clearly state: for pours exceeding 30 mm, use slow-curing, filled systems and staggered layer pours for process reliability. Reference tests such as thermal cycling and post-cure lap shear confirm the selection’s suitability in industrial workflows.

Quick-Reference Table: Techniques for Controlling Exothermic Reaction

| Technique | How it Helps | Best For |

|---|---|---|

| Layered Pouring | Lowers heat buildup per step | Deep clear castings, river tables |

| Additives / Fillers | Absorbs and distributes heat | Structural parts, electrical encapsulation |

| Slow-Cure Epoxies | Extends working time, lowers exotherm | Thick pours, embedded components |

| Cooler Environments | Slows reaction speed | All large-volume epoxy projects |

| Metal Molds | Draws heat away rapidly | Precision castings, electronics |

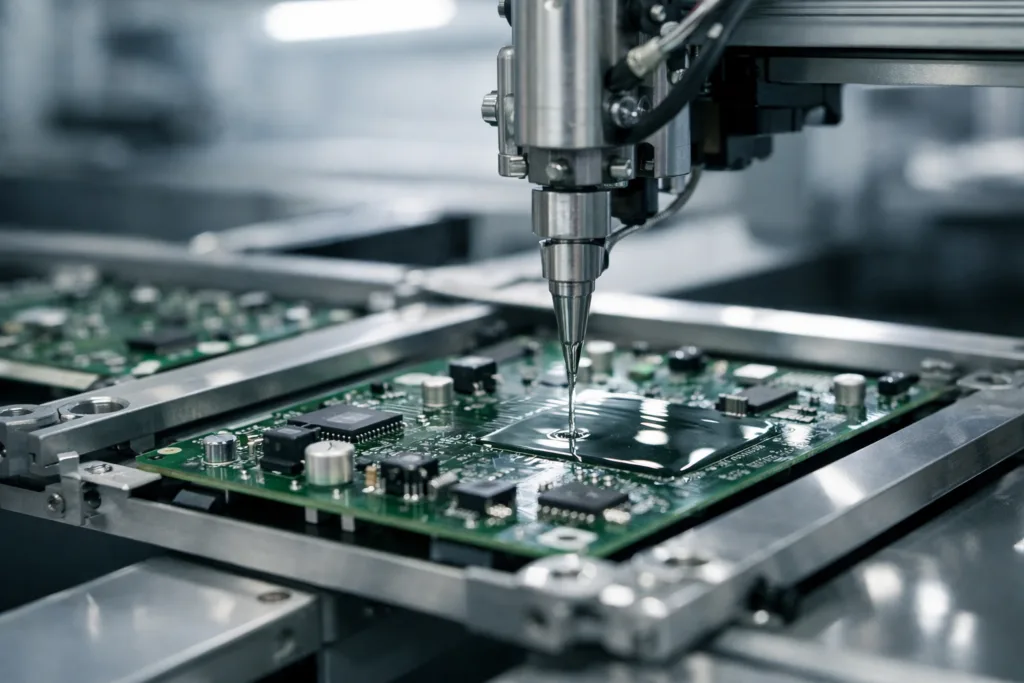

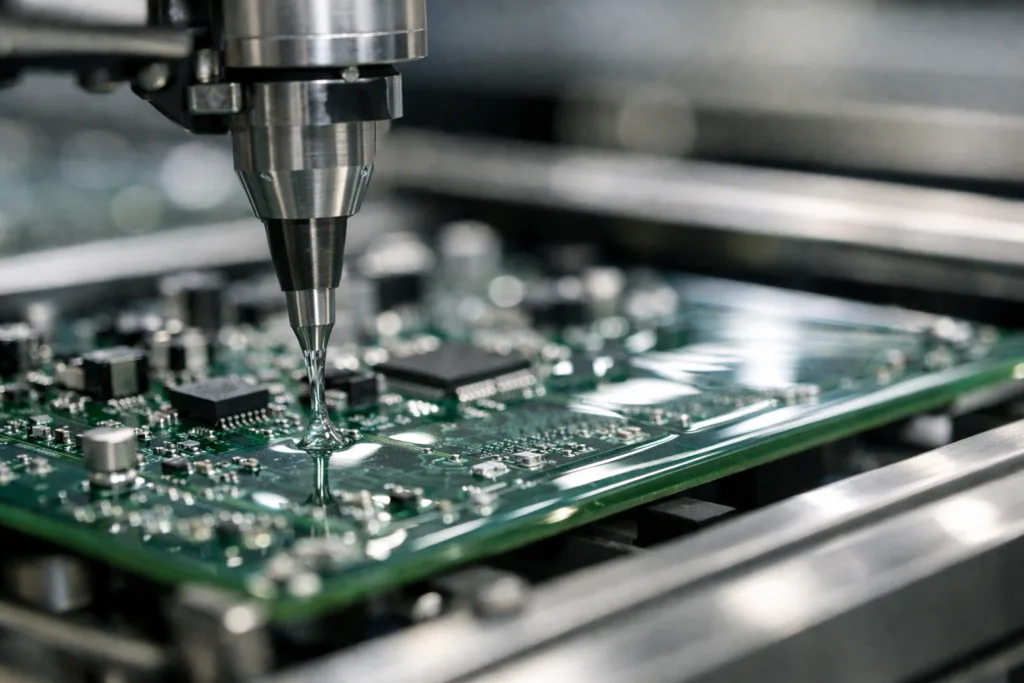

Real-World Applications: Why Exotherm Control Matters

Epoxy casting is foundational in industries like automotive (for mounting components), marine (for waterproof seals), and electronics (for potting and encapsulation). Failing to control the exothermic reaction leads to short circuits, structural failure, or even safety recall. For context, improper curing in battery modules can compromise potting compound reliability, so rigorous exotherm management is a non-negotiable quality step.

Controlling Exothermic Reaction in Large Epoxy Castings

To wrap up: controlling exothermic reaction in large epoxy castings comes down to understanding chemistry, precise process planning, and making smart material and equipment choices. The best results require patience, careful measurement, close monitoring, and learning from each pour. When the right steps are followed, even massive, crystal-clear epoxy castings are both beautiful and reliable.

Frequently Asked Questions

What is the main risk of uncontrolled exotherm in large epoxy projects?

Uncontrolled exothermic reactions can lead to overheating, cracks, bubbles, discoloration, incomplete cures, and in rare cases, fire or smoke. These risks are highest in thick or large-volume castings.

How thick can you safely pour epoxy at one time?

Most standard epoxies cure safely at 10–25 mm per layer. Specialized “deep-pour” systems may allow up to 50 mm, but always follow your supplier’s guidance and monitor temperature during curing.

Does adding fillers change the cure rate or heat output?

Yes, adding fillers reduces total exothermic heat and often slows the cure rate by providing more mass to absorb and dissipate heat, resulting in more controlled and even curing.

Is slow-curing epoxy always safer for large castings?

Generally, slow-curing epoxies offer more pot life and lower peak exothermic temperatures, making them suitable for large castings. Always test in your actual process conditions to confirm suitability.

What should you do if you notice the resin heating up too quickly?

Stop the process, move the batch to a cooler area, and if safe, spread the resin into a thinner layer to dissipate heat. Do not touch hot containers directly. Dispose of overheated resin according to safety guidelines.

Can I use any epoxy for electrical potting or industrial parts requiring large volume fills?

No. For large-volume or critical applications, select systems specifically designed to control exothermic reaction, ensure electrical safety, and maintain long-term durability under operational stresses.

Related Reading

- Discover How Low-Halogen Epoxies Shape Safer Green Electronics

- Expert Secrets: Prevent Water Damage in Epoxy Electrical Insulation

- 7 Proven Steps to Prevent Epoxy Yellowing and Maintain UV Resistance

- Unlock 13 Must-Know Epoxy Glass Transition Insights

- Power Up Manufacturing: 9 Breakthrough Benefits of B-Stage Epoxy Applications