Does UV Glue Really Work for Industrial Bonding?

Many engineers and plant managers ask, “Does UV glue really work for industrial bonding?” The answer depends on the bonding strength you need, the materials you use, and the curing conditions in your workflow. UV glues—also known as UV-curable adhesives—can deliver high performance when used correctly, especially for bonding plastics, glass, metals, and electronics parts. They cure fast under ultraviolet light and often create strong, durable bonds. However, it’s essential to understand their limits and compare them to other adhesive types for engineered strength.

Engineering Strength: Shear and Tensile Values Explained

When evaluating an adhesive for industrial use, two key measures are shear strength and tensile strength. Shear strength describes how well the glue resists forces that try to slide the bonded materials apart. Tensile strength shows how well it handles forces that pull the joint apart. Engineers often test these using standardized methods like ASTM D1002 for lap-shear and ASTM D638 for tensile testing.

Real-world numbers for UV glues are impressive on certain substrates. Some single-component UV adhesives can reach shear strengths of 12–20 MPa and tensile strengths of 15–25 MPa on glass or clear plastics. For example, ZDS’s UV-curable systems show lap-shear values up to 1,900 psi (13 MPa) on PC and PMMA after full cure. Compared to standard epoxies or polyurethanes, UV glues can match performance for relevant applications, but users must mind the curing depth and coverage.

| Adhesive Chemistry | Best Substrates | Lap-Shear Strength (MPa) | Tensile Strength (MPa) | Typical Uses |

|---|---|---|---|---|

| UV Acrylate | Glass, PC, PMMA | 12–20 | 15–25 | Electronics, Displays, Optical Parts |

| Epoxy (2K) | Steel, Aluminum, Composites | 24–32 | 30–50 | Automotive, Heavy Industry |

| PU (Polyurethane) | ABS, Plastics, Textiles | 10–15 | 12–20 | Flexible Parts, Foams |

| Silicone | Glass, Metal, Ceramics | 4–8 | 6–15 | Sealant, Vibration Isolation |

How UV Glue Strength Compares

While UV adhesives can rival engineered performance for glass, plastics, and select metals, they rarely match two-part epoxies for maximum lap-shear or tensile strength on rough substrates. Yet their rapid cure and clean finish offer big advantages for automated assembly or low-heat processes.

- UV adhesives excel on transparent materials.

- They simplify fixturing for precise electronics or optics.

- Surface prep matters: degrease, abrade, and fit parts closely for best results.

Real Industrial Use Cases: UV Glue in Action

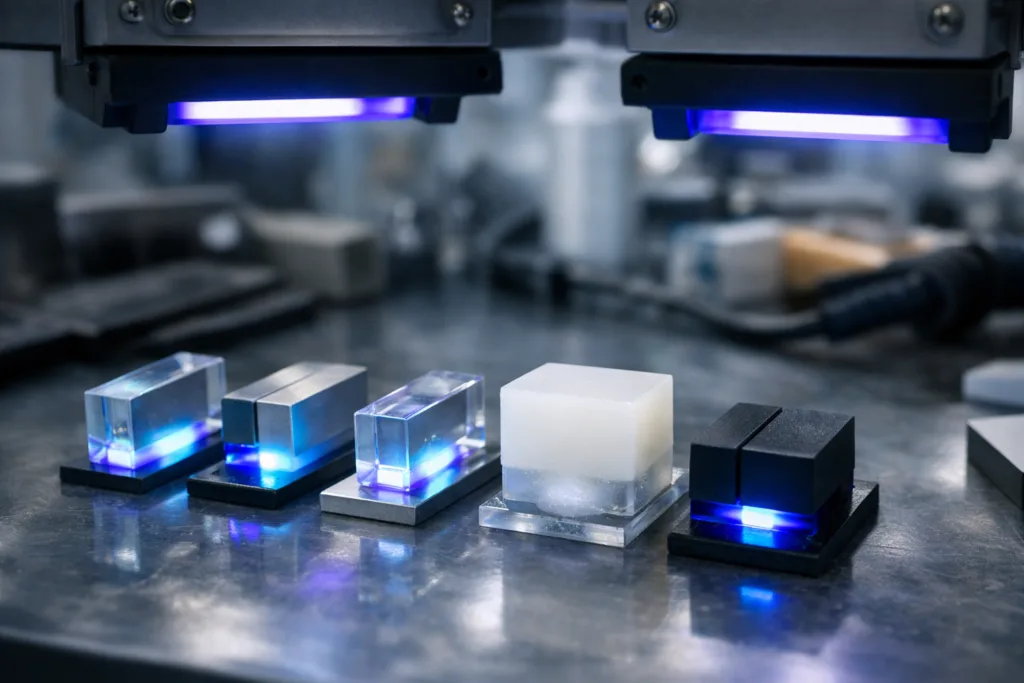

UV glue’s engineered strength becomes clear when you examine how manufacturers apply it in demanding projects. For example, electronics firms use UV adhesives for bonding touchscreens to glass covers. In production, operators dispense a precise bead, mate the parts, and expose the joint to 365 nm wavelength UV light. Cure time drops to just 5–30 seconds, so productivity soars. The finished bond resists shocks up to 15 MPa lap-shear, enough to withstand aggressive drop tests and vibration cycling.

In medical device assembly, companies fix transparent tubing and connectors with UV glue. The adhesive cures instantly under spot UV lamps, creating watertight joints that pass pressure leak tests (up to 2 bar) and sterilization cycles. ZDS works with device makers to optimize viscosity and cure speed for needle, tube, and cartridge sets. This fast cure avoids heat damage to sensitive polymers and supports high-throughput automation.

Automotive lighting makers use UV adhesives to assemble LED modules into polycarbonate housings. The bondline remains crystal clear, and lap-shear strength exceeds standard requirements for lens impact resistance. Unlike solvent-based adhesives, UV products give long open times and eliminate bubbles or gaps that weaken the joint.

Highlight Case: ZDS UV Glue for PC Display Bonding

One electronics tier supplier chose ZDS’s UV acrylate for bonding polycarbonate displays in heads-up modules. Their target was 1,500 psi (approx. 10 MPa) lap-shear after thermal aging. By using notched-trowel dispensing and controlled UV exposure (250 mW/cm² for 20 seconds), they achieved strong, bubble-free bonds that passed salt-spray and humidity cycling under ASTM B117 protocols. The process met ISO 9001 traceability and allowed quick shift turnovers without rework.

How UV Adhesives Cure: Process and Factors

UV glue hardens—or cures—when exposed to ultraviolet light between 250–400 nm. Most industrial glues activate with medium-intensity (200–400 mW/cm²) lamps, but thick joints or dark substrates may require higher intensities or special photoinitiators. Cure depth is usually limited to about 6 mm; shadowed areas won’t bond properly unless the glue contains dual-cure agents.

Mix ratio is simple: most UV glues are single-component, so no mixing errors. Typical viscosities range from 400 to 5,000 cP (centipoise), allowing syringe, jet, or slot-die application. Open time—the period before cure—is unlimited until light exposure. After UV hits, most glues reach handling strength in seconds; full mechanical properties (Shore D hardness 60–85) develop within 24 hours. Always check the SDS for cure kinetics and exotherm values to avoid thermal distortion in sensitive assemblies.

Surface Preparation and Bonding Tips

- Clean surfaces fully (IPA or acetone degreasing).

- Abrade or grit-blast for metals or composites where possible.

- Fit parts tight; large gaps (>0.4 mm) weaken joints.

- Verify lamp intensity and coverage—especially for complex geometries.

Limitations: When UV Glue Isn’t the Best Choice

Despite their strengths, UV glues aren’t suited for every job. If the substrate blocks UV light (like opaque metals or black plastics), the glue won’t cure deeply. The bond line must be visible to the light source. Assemblies with deep shadows or thick sections—over 6 mm—often require dual-cure adhesives that combine UV and heat or moisture curing.

Some industrial tasks need extra chemical or temperature resistance. For example, structural bonding of steel or aluminum in high-heat environments might require epoxy or polyurethane adhesives with higher glass transition temperatures (Tg above 120°C) and tensile strength beyond 40 MPa. UV glues typically max out at 90°C sustained exposure before degrading.

Also, repair jobs or maintenance in the field can prove tricky unless portable UV lamps and safety controls are available. ZDS recommends considering cure depth, substrate compatibility, and long-term durability when choosing adhesive types for mission-critical engineering projects.

Industries Where UV Glue May Fall Short

- Heavy machinery: welded steel, high-stress joints.

- Flooring: large stone slabs or concrete—opaque to UV.

- Outdoor electronics: high UV, wide temperature swings.

- Repair work: invisible bond lines or limited access to power.

ZDS and UV Adhesive Solutions

ZDS offers a wide range of adhesives—including UV-curable, epoxy, polyurethane, and silicone options—backed by ISO 9001 process controls. For industrial bonding, ZDS’s UV glues combine fast cure times, high clarity, and strong engineered performance for electronics, glass, and display parts. Their technical team supports clients with application development, quality assurance (including salt-spray and thermal cycle compliance), and custom formulations for tough assembly challenges.

Expert Takeaway:

“UV adhesives shine in automated lines, clear part assemblies, and electronics. Always match glue chemistry to your strength and environmental needs for lasting bonds.”

Does UV Glue Really Work?

So, does UV glue really work for industrial bonding? The answer is a confident yes—when used for the right applications. UV adhesives deliver fast curing, robust engineered strength on suitable substrates (especially glass and plastics), and support modern, automated manufacturing. However, they’re not a universal solution. Engineers should check lap-shear and tensile requirements, long-term durability, cure conditions, and substrate compatibility before choosing UV glue for mission-critical assemblies.

Key Performance Metrics and Compliance

Industrial users must verify each adhesive against the demands of their assembly. For UV glues, look for:

- Lap-shear strength (ASTM D1002): at least 10–14 MPa on glass/plastics.

- Tensile strength: target 15–25 MPa for reliable joints.

- Thermal cycling tolerance: up to 85–90°C sustained.

- Salt-spray and humidity resistance (ASTM B117).

- Documentation: REACH, RoHS, SDS, and lot traceability.

Making the Right Adhesive Choice

To choose the right adhesive, assess your process speed, material types, strength expectations, and environmental resistance needs. UV glue can be the ideal fit for modern assembly of electronics, displays, and optical devices. For heavy-duty, opaque, or outdoor joints, epoxies or structural polyurethanes may serve better. ZDS provides both standard and tailored solutions, helping manufacturers reach their reliability goals. Consult with a ZDS technical specialist for advice, samples, and performance validation.

Frequently Asked Questions

What is UV glue and how does it work?

UV glue is a single-part adhesive that cures rapidly when exposed to ultraviolet light, forming strong bonds especially on transparent materials.

What engineering strengths can UV glue achieve?

UV glues deliver lap-shear strengths of 12–20 MPa and tensile values up to 25 MPa, matching many industrial bonding needs for glass and plastics.

Where is UV glue best used in industry?

UV glue excels in electronics, medical devices, displays, and optical assemblies requiring fast, clear, and robust bonding.

Are there limits to UV glue’s applications?

Yes, UV glue won’t cure on opaque substrates or thick sections and may lack heat or chemical resistance needed for some industrial uses.

What performance standards apply to UV glue?

Key standards include ASTM D1002 for lap-shear, ASTM B117 for salt spray resistance, and REACH/RoHS for compliance documentation.

How can ZDS help with UV industrial adhesive selection?

ZDS provides technical advice, sample testing, and custom UV adhesive solutions tailored to each client’s engineering and process needs.