Overview: High-Temperature Industrial Adhesives (150°C–300°C Solutions)

Heat is unforgiving. It strains connections, tests every joint, and shatters weak bonds. High-temperature industrial adhesives—those rated for sustained exposure from 150°C up to 300°C—solve problems where traditional glues fail. Leading Industrial Adhesives manufacturers, including ZDS, give engineers the tools to secure engine covers, electronic assemblies, and energy equipment with adhesives built for extremes.

- Automotive engine parts face cycles above 200°C.

- Electronic systems run hot in power modules, IGBT packaging, and sensors.

- Energy equipment, from wind turbines to industrial heaters, need lasting bonds under relentless heat.

This guide explores the key adhesive chemistries, properties, and practical details required to choose, test, and apply heat resistant adhesive solutions that keep components intact under extreme temperatures.

Applications for High-Temperature Industrial Adhesives

Not all heat resistant adhesives are created equal. The site of application, required temperature endurance, and substrate material decide which solution performs best. Below are three critical sectors where high-temperature adhesives play a vital role.

Automotive Engines and Powertrain Components

Engine assembly areas—including cylinder heads, exhaust systems, turbochargers, and transmission housings—often need adhesives that survive thermal cycling above 250°C. Traditional fasteners can fail under vibration or corrosion, but advanced adhesives offer vibration-dampening and sealing with superior reliability. ZDS provides epoxy and silicone solutions tailored for these dynamic thermal ranges.

Electronics: Power Modules and PCBs

Electronic devices, especially power electronics such as inverters and semiconductor modules, generate intense local heat. High-temperature adhesives here ensure robust bonds for heat sinks, and critical encapsulation for components—while withstanding thermal shock and fluctuating loads. Acrylics and polysilicones with glass transition temperatures (Tg) over 175°C are commonly specified.

Energy Equipment & Industrial Machinery

Energy sector components—solar panels, wind turbine nacelles, battery packs, switch gears, and industrial heaters—require adhesives that hold up against both high heat and adverse chemicals. Silicone and epoxy systems with enhanced temperature stability—and built-in flexibility—are often the engineer’s top choice.

- Turbine blades: Adhesive joints must handle both high heat and cyclical stress.

- Heater elements: Bonds get exposed to continuous 200°C+ temperatures.

- Switchgear: Adheres to ceramics, metals, and composites in harsh environments.

High-Temperature Industrial Adhesives (150°C–300°C Solutions)

The market offers adhesives rated for everything from mild warmth to extreme heat. To select properly, users must understand heat resistant adhesive chemistry, cure mechanisms, and how each system interacts with chosen substrates under thermal stress.

Adhesive Chemistries Suited for High Temperatures

| Type | Max Temp (°C) | Cure Mechanism | Best Substrates | Typical Uses |

|---|---|---|---|---|

| Epoxy (1K/2K) | 180–260 | Heat, Room Temp | Metal, Composite, PCB | Engines, Electronics, Energy |

| Silicone | 200–300 | RTV (Room Temp Vulcanize), Heat | Glass, Metal, Ceramic | Automotive, Industrial Seals |

| Acrylic (Heat Cure) | 150–220 | UV, Heat | Metal, Plastic, Composite | PCBs, Sensors |

| Polyurethane (PU) | 130–160 | Moisture, Heat | Plastic, Rubber, Metal | Mounts, Insulation |

| Hybrid/MS Polymer | 140–180 | Moisture | Stone, Concrete, Metal | Flooring, Energy Devices |

Key Thermal Properties and Testing

- Glass Transition Temperature (Tg): Above Tg, material softens or weakens. For sustained high-temperature use, adhesives need Tg ≥ 180°C.

- Lap Shear Strength: Measures bonding under stress (see ASTM D1002).

- Chemical Resistance: Must withstand oil, coolant, fuel, cleaning agents—plus salt spray corrosion (ASTM B117).

- Thermal Cycling: Adhesives must retain strength after repeated temperature swings.

Leading ZDS offerings include epoxies tested for 1200+ hour salt spray and silicone formulas passing up to 200 thermal cycles between -40°C and 250°C.

Choosing the Right Heat Resistant Adhesive for Your Application

The choice isn’t only about temperature. Application method, substrate type, and mechanical demands must be considered together. Here’s how decision makers filter options:

- Temperature Range: Ensure adhesive’s working temperature suits your peak thermal load.

- Substrate Compatibility: Metals, ceramics, glass, polycarbonate (PC), polyamide (PA), and composites. Surface prep—such as degreasing or plasma treatment—increases bond strength.

- Cure Process: Some systems require heat or UV, others cure at room temperature (RTV).

- Mechanical Properties: Hardness (Shore A/D), flexibility, shock absorption.

- Dispensing: Bead, slot-die, notched trowel, static mixer for 2K systems, automated lines.

Substrate Preparation: Maximizing Adhesion

Clean surfaces make or break a bond. Remove oils and dust, then abrade for texture. For plastics like PP or PA, corona or plasma treatment gives better wettability. Primers or adhesion promoters boost initial tack and final strength especially on oily metals or composites.

Application Methods and Process Control

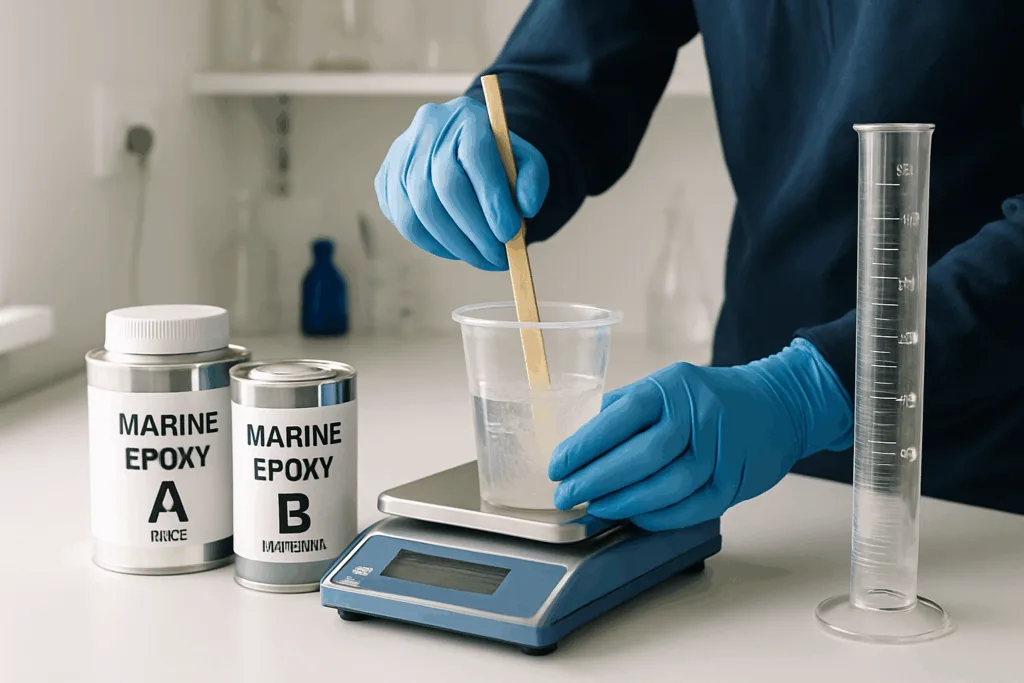

- Epoxies: Mix in exact ratios, dispense with static mixers.

- Silicone: Cartridge or automated bead; cure by humidity or temperature.

- Tape/film: Die-cut for fast, precise assembly—ideal for electronics.

Fixturing and clamping—especially for engine and structural assemblies—help adhesives reach optimal bonding under minimum pressure.

Performance Metrics: Testing High-Temperature Adhesives

Every serious industrial adhesive for high-temperature use must clear a battery of tests before deployment. Key performance metrics include lap shear, tensile strength, elongation, temperature cycling, and chemical exposure endurance.

Lap Shear and Peel Strength

Lap shear (ASTM D1002) simulates real-world loads. Silicone formulas often hit 8–12 MPa; 2K epoxies reach 15–35 MPa at 200°C. For peel, ASTM D1876 gauges flexibility and bond reliability under delamination. ZDS adhesives target 25–40 N/cm T-peel in engine gaskets.

Thermal and Chemical Resistance

Test cycles expose adhesives to full temperature ranges plus harsh fluids. Success means surviving 250°C dry heat, plus salt spray, engine oil, or coolants—without embrittlement or swelling.

Quality, Safety & Regulatory Compliance

- Certifications: REACH, RoHS, ISO 9001 for global deployment.

- Documentation: Safety data sheets (SDS), lot traceability.

- Low VOCs and full compliance for sustainable manufacturing.

Epoxy, Silicone, and Advanced Adhesive Systems

Epoxy adhesives, especially 2K (two-part) versions, offer outstanding shear and peel values plus heat and chemical resistance. Curing methods vary—some need elevated heat (up to 120°C bake), others activate at room temperature. Silicone adhesives excel in both temperature stability and flexibility, remaining elastic up to 300°C. Hybrid polymers, like MS polymer and heat-cure acrylics, fit niche requirements, especially when bonding mixed materials or needing quick throughput.

Benefits and Limitations by Chemistry

- Epoxy: High strength, best for metal-to-metal and metal-to-composite bonds; some rigid, some flexible forms.

- Silicone: Top choice for vibration, thermal expansion, and extreme heat; also acts as a sealant.

- Acrylic: Moderate heat resistance, rapid cure; popular for electronics.

- Polyurethane: Best for shock absorption but limited to ~160°C.

Case Studies: Automotive, Electronics, and Energy Equipment

These scenes show how high-temperature industrial adhesives make a difference out on the manufacturing floor.

Automotive Engine Bonding

A major OEM replaced traditional bolts on turbocharger heat shields (enduring 250°C thermal cycling) with ZDS’s 2K epoxy solution. Long-term lap shear held at 29 MPa after 500 cycles, with zero failures in vibration tests.

Power Module Encapsulation

Electric vehicle inverter modules leverage ZDS silicone adhesives for their dual resistance to thermal shock and humidity. Modules pass 1,500+ hours at 220°C with full electrical insulation—where standard epoxies lost shape beyond 200°C.

Energy Sector Assembly

Wind turbine manufacturers need blade bonding adhesives that resist both high heat and constant flex. ZDS developed hybrid MS polymer formulas, achieving stable bonds after 2,000 hours at 180°C and continuous salt spray exposure.

Innovation Trends in High-Temperature Industrial Adhesives

The arena moves fast. Manufacturers focus on smarter formulas, sustainability, and speed. ZDS leads with new advancements in low-VOC, ultra-high Tg epoxies and thermally conductive silicones. These products shrink cure times, boost energy efficiency, and help clients meet tougher environmental and safety standards. Across industries, automation and robotics drive demand for drop-in adhesives compatible with high-speed lines, customized dispensing, and precise QC tracking.

Future-Focused Features

- Thermally conductive adhesives—manage heat in electronics, batteries, and engine parts.

- High-performance hybrid systems—for flexible assembly lines and mixed materials.

- UV-curable bonds—speed up electronics and sensor assembly.

Quality Control and Best Practices for Reliable Bonding

Reliability stands on two legs: formulation and process. No matter how advanced the adhesive, incorrect handling ruins a bond. Top manufacturers, including ZDS, back each batch with ISO 9001 traceability and provide detailed mixing, storage, and cure instructions.

Critical Tips for High-Temperature Bonding

- Store adhesives as per SDS—most lose potency outside recommended temperature/humidity.

- Verify dispensing tools—check calibration before production starts.

- Follow exact mix ratios for 2K systems—for consistent cure and maximum performance.

- Allow full cure before loading; stress premature bonds and you risk failure at high temperatures.

- Document each step—keep records for future Q/A audits and warranty support.

Expert takeaway: “A high-temperature adhesive is only as reliable as the process supporting it. Never skip substrate prep, and always verify cure about resistance to heat and stress.”

Frequently Asked Questions

What defines a high-temperature industrial adhesive?

A high-temperature industrial adhesive can consistently withstand temperatures of 150°C–300°C without losing strength or flexibility.

Which chemistry offers the highest heat resistance?

Silicone adhesives provide top heat resistance, performing reliably in environments up to 300°C with strong elasticity.

How important is substrate preparation?

Proper cleaning and abrasion of the substrate are crucial for strong bonds and long-term heat resistance in high-temperature adhesives.

Can these adhesives work on plastics like PP or PA?

Yes, but success depends on surface treatments like plasma or corona discharge, and use of adhesion-promoting primers.

What tests confirm durability under heat?

Lap shear tests, peel strength, thermal cycling, salt spray (ASTM B117), and chemical resistance trials confirm heat durability.

Are these adhesives safe and compliant for manufacturing?

Top brands like ZDS offer adhesives certified to REACH, RoHS, and ISO 9001 and supply full SDS documentation for manufacturing safety.