Why UV Curing Adhesives Transform Electronics Assembly

Electronics makers need speed, reliability, and performance when building devices like PCBs, sensors, and connectors. One material stands out: UV curing adhesive for electronics. This technology delivers rapid positioning, strong electrical insulation, and superior process control. Let’s explore how UV solutions streamline electronic assembly and raise the bar for quality.

UV Curing Adhesives for Electronics: Key Features and Advantages

UV curing adhesives for electronics offer outstanding benefits over traditional glues and heat-cured resins. These materials set within seconds under ultraviolet light, enabling precise placement and faster throughput. ZDS formulates these adhesives to meet strict performance demands in PCB, connector, and sensor assembly.

- Instant cure with UV exposure

- No heat impact on sensitive electronics

- Strong bonds to metals, plastics, glass, and ceramics

- Clean processing and minimal waste

- Excellent insulation and environmental resistance

How UV Chemistry Works

UV adhesives contain photoinitiators. When exposed to a specific wavelength of light, these molecules trigger rapid curing reactions. This process forms a tough, flexible polymer network inside seconds without external heat.

Main Types of UV Curing Adhesives

| Chemistry | Best Substrates | Properties | Common Uses |

|---|---|---|---|

| Acrylic | Glass, plastics, metals | Fast cure, high clarity, flexible | LCDs, sensors, protective coatings |

| Epoxy | Metals, PCBs, ceramics | High strength, insulation, chemical resistance | PCB bonding, potting, structural joins |

| Hybrid | Mixed substrates | Balanced cure, shock resistance | Connectors, flexible circuits |

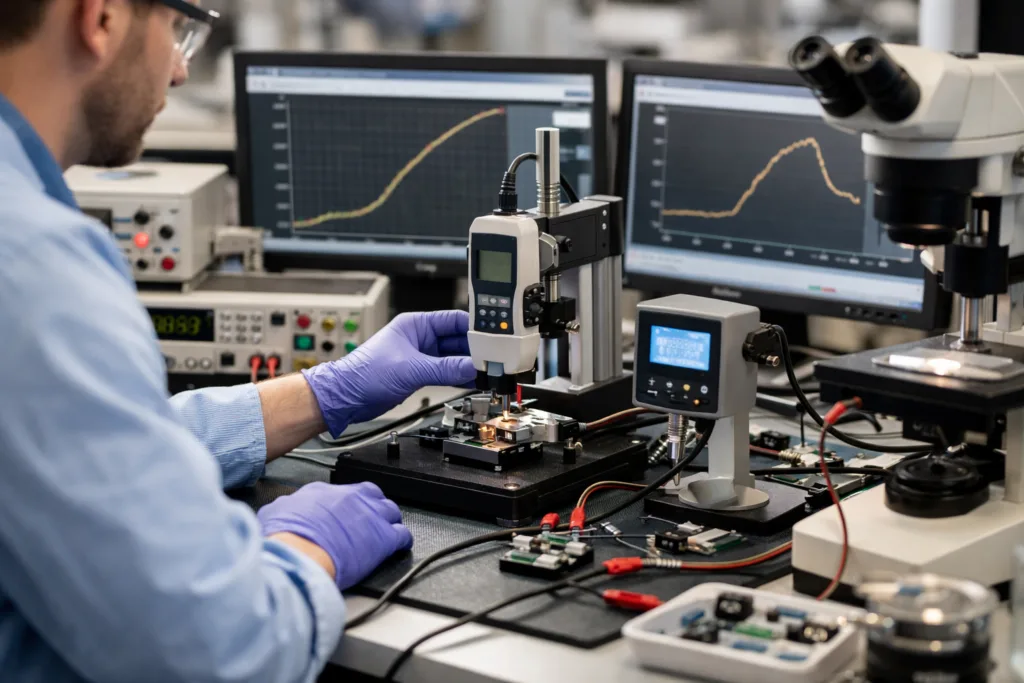

Rapid Positioning for Modern Assembly Lines

Speed matters in electronics. UV curing adhesives fix components rapidly, letting production lines move faster. Automated dispensing with bead or slot-die coating ensures repeatable coverage. Parts are aligned, spot-cured with UV, and ready for next steps immediately.

Applications: PCB, Sensor, and Connector Bonding with UV Curing Adhesive for Electronics

Electronic makers rely on UV curing adhesives for several critical assembly operations. ZDS supplies custom solutions to fit PCB, sensor, and connector manufacturing needs.

Printed Circuit Boards (PCBs)

PCBs form the backbone of all electronic devices. UV adhesives bond components, reinforce wire connections, and insulate traces. Their fast cure prevents movement during placement and testing.

Surface Mount Device (SMD) Attachment

UV adhesives are dispensed under SMD pins or leads to lock parts while soldering. Quick UV flash keeps components firmly positioned.

Coil & Transformer Potting

Liquid UV resins encapsulate delicate coils, preventing vibration and moisture ingress. Their insulating nature protects against shorts and electrical faults.

Sensors

Modern sensors demand compact design and precise alignment. UV adhesives fill tiny gaps, shield connections, and seal sensitive elements against air or liquid ingress.

- Glass-to-metal or plastic seals

- Wire insulation and strain relief

- Transparent optical bonding

Connectors

Connectors need strong bonds and quick fixation to maintain data and power integrity. UV adhesives securely attach pins, pads, and cable sheaths without affecting conductivity.

- Align contacts and apply adhesive

- UV cure for instant hold

- Retention and insulation with minimal cure shrinkage

Electrical Insulation Benefits of UV Curing Adhesive for Electronics

Electrical insulation is crucial inside crowded electronic assemblies. UV curing adhesive for electronics provides excellent dielectric strength, often exceeding 25 kV/mm. This ensures safe operation and extends device lifespan.

Dielectric Properties & Standards

UV adhesives for electronics pass strict tests like ASTM D149 for dielectric breakdown. Top formulations from ZDS can reach insulation resistance over 1012 Ω, supporting signal integrity in sensors and PCBs.

Heat and Chemical Stability

Many UV adhesives are engineered to withstand elevated temperatures and harsh chemicals, safeguarding insulation over time. Typical operating ranges run from -40°C to 150°C.

Fast Fixation and Precise Placement

Speed sets UV curing adhesives apart. Pinpoint application with automated dispensers or manual syringes lets manufacturers position tiny parts with tight tolerances. Quick UV cure prevents drift or misalignment.

Open Time and Cure Control

Cure control is flexible. Operators have generous open time to align parts before activating UV cure. Exposure times range from 2–30 seconds depending on thickness, lamp power, and adhesive chemistry.

Process Efficiency Gains

Production lines move faster with UV technology. No oven curing means lower energy use, reduced footprint, and shorter changeover times. Consistent, instant cure boosts yield and reliability.

Manufacturing Process Advantages of UV Curing Adhesive for Electronics

Switching to UV curing adhesive for electronics offers unique process advantages compared to heat-cure or two-part systems. Manufacturers see improvements in throughput, quality control, and product consistency.

Cleanroom Compatibility

UV adhesives release little to no volatile organic compounds (VOCs), supporting ISO 14644 cleanroom requirements. Low outgassing keeps sensitive instruments safe during production.

Process Automation

UV adhesives integrate smoothly with automated lines. Static mixers, nozzle robots, and UV lamps work together for fast, repeatable cure. Pot life is unlimited until exposure.

Quality Assurance & Compliance

Every batch must meet REACH, RoHS, and VOC standards. ZDS tracks lot data and issues full safety (SDS) documentation. In-line vision and cure checks maintain perfect bonds every cycle.

Substrate Compatibility and Surface Preparation

UV curing adhesives stick to a wide range of substrates. Common electronics bases include ABS, PC, PA, PP plastics, copper, FR4 (glass-epoxy), and ceramics. Proper surface prep maximizes bond strength.

Surface Cleaning and Activation

- Degrease parts with approved solvents

- Abrade with fine grit for roughness

- Apply adhesion promoters to tough plastics (corona/plasma)

Fixture and Clamping Methods

Assembly lines use jigs, clamps, or temporary supports for precise alignment. UV cure then locks components instantly, with typical lap-shear strengths of 10–40 MPa after cure (see ASTM D1002).

Testing, Inspection, and Reliability

Reliability is non-negotiable in electronics. UV adhesives must pass tough testing: salt spray (ASTM B117), thermal cycling, accelerated aging, and electrical stress. ZDS audits each batch and supports full QC trails for mission-critical builds.

Nondestructive Inspection

Fluorescent UV adhesives can be checked under blacklight. Operators detect missed spots or incomplete bonds easily, enabling instant rework before final test.

Long-Term Aging

UV cures retain strength, flexibility, and insulation after thousands of hours exposed to heat, humidity, and vibration. Leading grades offer a Shore A/D hardness range suited for both rigid and flexible applications.

UV Curing Adhesive for Electronics

UV curing adhesive for electronics has revolutionized how manufacturers build PCBs, sensors, and connectors. The combination of instant cure, high reliability, and broad substrate compatibility means faster, cleaner, and more cost-effective assembly. ZDS continues pushing UV adhesive technology, delivering custom solutions for next-generation electronics.

Expert Tips: Selecting the Right UV Curing Adhesive for Electronics

Choosing the best adhesive depends on your application. Consider these factors:

- Part geometry and gap size

- Substrate material and surface finish

- Electrical insulation rating needed

- Temperature and chemical exposure

- Required fixture and automation level

- Regulatory (REACH/RoHS/VOC) compliance

Expert Takeaway: Consult adhesive manufacturers like ZDS early in design to match technology with your reliability and throughput needs.

Frequently Asked Questions

What is a UV curing adhesive for electronics?

It is a glue that hardens quickly under ultraviolet light, bonding and insulating components in electronic assemblies like PCBs, sensors, and connectors.

How fast do UV curing adhesives set?

Most UV curing adhesives for electronics cure in 2–30 seconds under focused UV lamp exposure, allowing rapid production and positioning.

Are UV curing adhesives electrically insulating?

Yes. These adhesives provide very high electrical insulation, often exceeding 25 kV/mm, protecting against shorts and leakage paths.

What surfaces work best with UV curing adhesives?

They bond to metals, plastics, glass, ceramics, and composite PCB materials. Proper cleaning and surface activation improve adhesion.

Do UV curing adhesives support automated assembly?

Absolutely. They can be dispensed by robots, set instantly with UV lamps, and integrated into automated process lines for consistent results.

Are UV curing adhesives safe and compliant for electronics?

Quality UV adhesives meet REACH and RoHS rules, with low VOC emissions and full traceability, making them suitable for cleanroom electronics.