Defining Performance: Why Waterproof & Outdoor Industrial Adhesives Matter

Outdoor environments punish fasteners, seals, and bonds in ways that indoor conditions do not. Waterproof industrial adhesives must withstand rainfall, temperature swings, and direct sunlight across months or years of exposure. Today’s outdoor industrial glue combines toughness, flexibility, and chemical resistance. For construction, electrical cabinets, HVAC housings, and utility equipment, a reliable adhesive keeps structures intact and assets protected from leaks, rust, and weather damage.

- Moisture protection: Bonds should remain closed—even when fully submerged or soaked.

- UV resistance: Adhesives need chemistry that resists sunlight-driven embrittlement and yellowing.

- Thermal cycling: Outdoor glues cope with freeze-thaw, heatwaves, and rapid temperature jumps without cracking.

Waterproof & Outdoor Industrial Adhesives

For site engineers, procurement leads, and fabricators, selecting the right waterproof industrial adhesive is not a one-size-fits-all task. The application—be it a wind turbine blade, streetlight, cabinet, or external wall panel—dictates the optimal choice. This section reviews the most common chemistries used outdoors, their standout properties, and practical application tips. ZDS, a specialist in adhesives for demanding environments, offers a range of solutions adaptable to these needs.

| Chemistry | Best Substrates | Weather Resistance | Typical Uses |

|---|---|---|---|

| Epoxy (1K/2K) | Metals, composites, stone, glass | Excellent moisture, moderate UV (with fillers) | Facade panels, heavy equipment, anchor bolts |

| Polyurethane (PU) | Plastic, metals, wood, concrete | Superb moisture, fair UV (aliphatic PU = high UV) | Door frames, expansion joints, outdoor sealants |

| Silicone | Glass, ceramic, metal, engineered plastics | Outstanding UV, weather, moisture | Solar PV, window seals, enclosure gasketing |

| Acrylic | Plastics, metal composites | Good moisture, strong UV | Signage, panels, electrical housings |

| MS Polymer/Hybrid | Stone, tile, metals, plastics | Very high all-weather, moderate UV | Facade fixings, roof tiles, prefab modules |

Key Requirements for Tough Outdoor Bonds

In outdoor industrial glue applications, weather is the constant enemy. Rainwater causes corrosion and creep. Solar UV can break down unprotected plastics or organic ingredients within the adhesive. Fluctuating temperatures produce expansion and contraction, testing flexibility. The following criteria guide adhesive selection:

- Waterproofing: Choose adhesives that pass strict immersion and spray tests, like ASTM D1002 lap shear after water exposure, or ASTM B117 salt spray for corrosion-prone joints.

- UV Resistance: For exposed bonds, select chemistries that do not turn brittle or yellow after weeks under UV-A lamps or actual sun.

- Chemical Stability: Outdoor adhesives should resist acid rain, airborne pollutants, and even bird droppings, which can degrade some glues.

- Thermal Expansion: Select flexible systems or hybrids (for example, MS polymer) for substrates with very different coefficients of expansion.

Expert takeaway: “On exposed building envelopes, insulation mounting, and façade assemblies, a high-performance adhesive is the invisible guard against weather leaks and delamination. Testing for both tensile (MPa) and peel strength (N/25mm) after environmental cycles reveals the true resilience.”

Substrate Preparation and Key Installation Steps

All glues need a clean, prepared surface. For metals, degreasing followed by abrasion (ideally grit-blasting) helps remove oxidation and increases anchor points. Plastics like PP, PE, or PA may require corona or plasma treatment, or primer. Here’s a proven sequence for durable external bonding:

- Degrease: Remove oils and dust with a lint-free wipe and solvent.

- Abrade: Sand or blast for mechanical keying, especially on shiny or slick surfaces.

- Treat: For difficult engineered plastics, apply primer or surface activation.

- Dispense: Use static mixers for 2K formulas, bead guns for precise application, or slot-die/roller for large areas.

- Clamp/Fixture: Apply moderate pressure while the adhesive cures. Open time and set time depend on temperature and chemistry (epoxies can range from 5 to 60 minutes; MS/PU hybrids set in 20–40 minutes at 23°C).

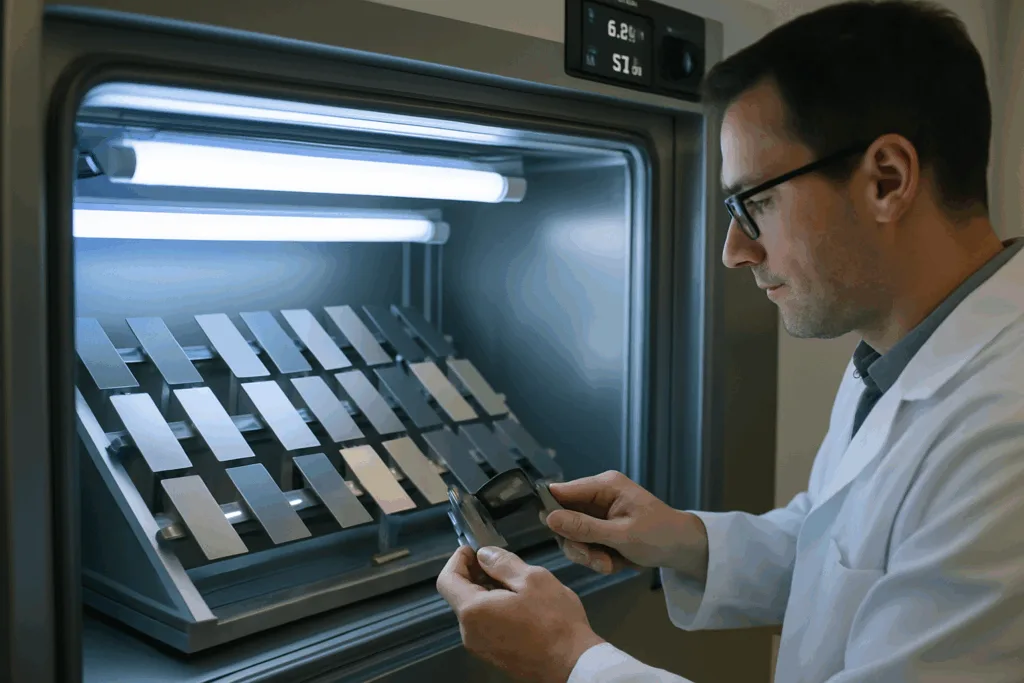

The Science of Durability: UV, Moisture, and Temperature Resistance

Outdoor adhesives must pass harsh durability testing. For UV, industry labs use accelerated weathering testers: powerful UV-A/UV-B lamps, temperature cycles, and humidity exposure to simulate years in weeks. Quality adhesives maintain over 80% of their original lap-shear and peel strength (based on ASTM D1002 and D1876) after 1,000+ hours in these chambers. Moisture resistance is measured by submersion, salt spray (ASTM B117), and wet–dry cycling that attacks weaker bonds. Temperature cycling, ranging from –30°C to +80°C or greater, checks for embrittlement and creeping under load. ZDS subjects its outdoor lines to these rigorous controls, ensuring performance in the wild.

Sample Property Targets

- Lap shear (metal-metal): 10–30 MPa after 1,000 hours weathering

- T-peel strength: 5–15 N/25mm post-UV aging

- Elongation at break: 80–400% for flexible sealant-adhesive hybrids

- Operating range: –40°C to +120°C for top-grade adhesives

Application Examples: Construction, Power, and Outdoor Equipment

Waterproof industrial adhesives are the unsung heroes on jobsites, power substations, and rooftops. In building and construction, outdoor glues attach exterior wall panels, window frames, and roof tiles. Epoxies anchor mounting brackets for solar and HVAC units. Polyurethane and MS polymer sealants bridge expansion joints and fix façade details, enduring sun and rain over decades.

In electrical infrastructure, adhesives create hermetic seals in outdoor switch cabinets, substations, LED lighting enclosures, and cable glands. Here, UV resistance and moisture proofing are vital to prevent shorts and corrosion. Power lines, signal boxes, and temperature sensors often rely on weatherable, quick-set caulks or pre-cured tapes for field repairs. ZDS provides specialized formulas for lasting performance in harsh field conditions.

- Facade cladding and insulation systems

- Power distribution boxes, outdoor junctions

- Precast concrete modules and site fixtures

- Utility cabinet weather-sealing

- Outdoor sign and lighting assembly

Process Control, Safety, and Compliance

Performance is only as good as process control. Automated mixing and dispensing, correctly set bead widths, and calibrated cure cycles all enhance reliability. Regular QC checks—viscosity, mix ratio, pot life—avoid failures due to off-spec material. Many outdoor jobs also mandate compliance documents: ISO 9001 traceability, VOC content (for green building), REACH/RoHS certification, and full SDS handling information. For safety, consult adhesive product datasheets, use gloves and suitable PPE, and maintain good ventilation during application and cure. Ship and store adhesives per manufacturer guidelines—many must be kept sealed and at stable temperatures for maximum shelf life.

Troubleshooting and Field Repairs

Even the best adhesives can run into trouble outdoors. Common signs of joint failure include yellowing (from UV), edge lifting (from water ingress), white residue (salt or chemical attack), and softening (from heat or plasticizer migration). Quick fixes use compatible patch materials, spot-injected liquid glues, or peel-and-stick tapes for rapid restoration. For major repairs, prepare the surface again and apply new adhesive per the original procedure.

- Match repair adhesive to the original chemistry when possible

- Eliminate water and debris from the joint zone before re-bonding

- Check underlying cause: investigate for repeated water pooling, substrate movement, or excessive solar loads

Buyer Guidance: Selecting the Best Outdoor Industrial Glue

The right waterproof industrial adhesive balances performance, workability, and long-term value. Consider these questions to make the best choice:

- What substrates must be bonded? (Metal, plastic, stone, composites)

- Will joints face submersion or only surface rain?

- Is UV exposure direct and prolonged?

- Are fast turnarounds vital? (Look for quick-cure or UV-cure adhesives.)

- Does the project require non-sag, gap-filling, or high-flex formulas?

Consult with material specialists or a supplier like ZDS, who can help test for compatibility, recommend primers, and supply samples for on-site evaluation. With the right investment up front, outdoor bonds can last for decades under all weather.

Frequently Asked Questions

What makes an industrial adhesive waterproof?

Waterproof adhesives create a continuous seal that resists water penetration, even under immersion or prolonged wet conditions.

Which adhesives are best for UV resistance outdoors?

Silicones and some specialty polyurethanes provide outstanding UV resistance, keeping bonds stable and flexible after long sun exposure.

How to prepare surfaces for outdoor adhesive bonding?

Degrease, abrade, and—if needed—prime the surfaces to ensure maximum adhesion and long-term outdoor durability.

Can one adhesive bond all types of outdoor substrates?

No single adhesive bonds all substrates equally well. It’s critical to match adhesive chemistry to the specific materials used.

What performance tests prove outdoor adhesive reliability?

Lap-shear after weather exposure, peel strength, UV aging, salt spray, and thermal cycling tests measure real outdoor reliability.

How long do outdoor industrial adhesives last in the field?

Most high-quality adhesives last over 10–20 years outdoors, provided correct surface prep and application methods are followed.

Related Reading on Industrial Adhesives

-

- Industrial Adhesives – Applications, Materials & OEM Solutions

- Industrial Adhesives: Types, Applications, and Selection Guide

- Industrial Silicone Adhesives: High Flexibility & Temperature Resistance

- Adhesive Solutions for Renewable Energy (Solar, EV, Wind)

- Common Industrial Adhesive Failures & How to Avoid Them