Understanding UV Adhesives

What are UV adhesives? These special bonding agents cure—harden and set—when exposed to ultraviolet (UV) light. Instead of relying on heat or moisture, UV adhesives use light to trigger chemical bonds in the liquid material. This results in a fast, precise, and reliable bond for many industrial applications.

Defining UV Adhesive

UV adhesive is a type of liquid glue that contains compounds called photoinitiators. When these compounds absorb UV light, they start a chemical reaction that turns the adhesive from liquid to solid. This process creates a strong bond between two surfaces with minimal waiting time.

Why Choose UV Adhesives?

- Rapid curing in seconds to minutes

- Precise control of when and where adhesive hardens

- Minimal heat required, protecting sensitive components

Photoinitiated Cure Mechanism

At the heart of UV adhesives is the photoinitiator. Think of this ingredient as a trigger. Under UV light, the photoinitiator breaks apart and creates reactive particles. These drive a polymerization reaction, causing chains of molecules to link together and form a solid material.

Types of Photoinitiators

- Norrish Type I: Directly splits under UV light, releasing free radicals.

- Norrish Type II: Requires another molecule to help the process, increasing the options for custom adhesive formulas.

Key Polymerization Chemistry

Most UV adhesives use acrylate or epoxy chemistry. Acrylate-based formulas deliver fast cures and flexible bonds. Epoxy UV adhesives, like those offered by ZDS, provide high strength and chemical resistance for demanding tasks.

| Chemistry | Substrates | Main Properties | Best Uses |

|---|---|---|---|

| Acrylate | Glass, plastics, metals | Flexibility, clarity | Optical devices, electronics |

| Epoxy | Metals, ceramics | High strength, durability | Medical devices, automotive |

| Silicone | Soft elastomers, films | Elasticity, heat resistance | LEDs, sensors |

Breaking Down the UV Cure Process

The transition from liquid to solid with UV adhesives is simple, but the science is remarkable. Here’s how the process unfolds:

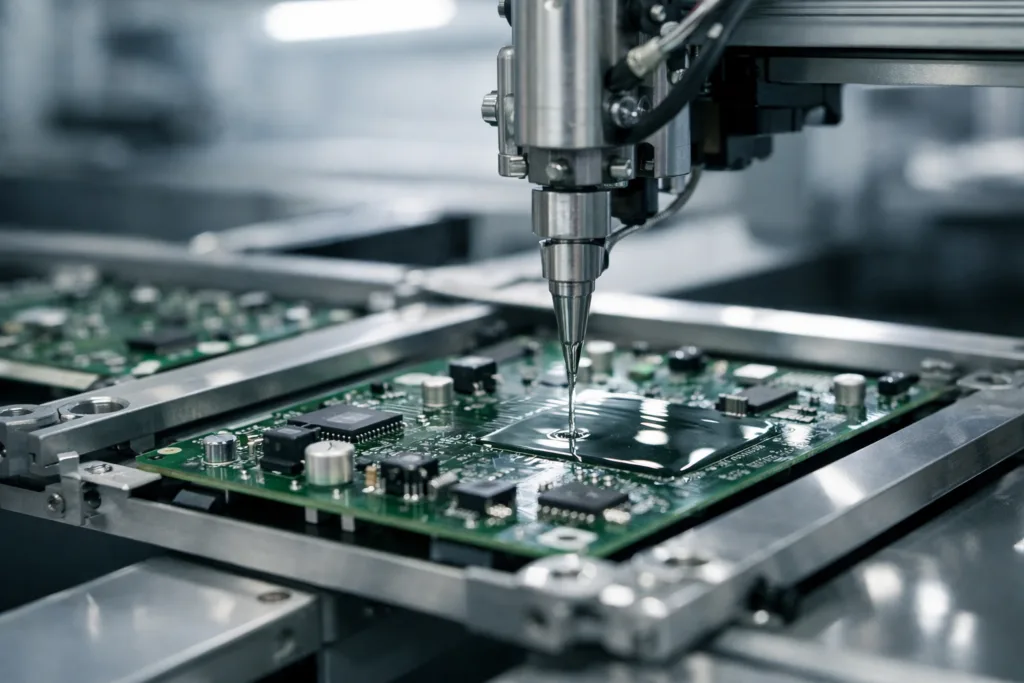

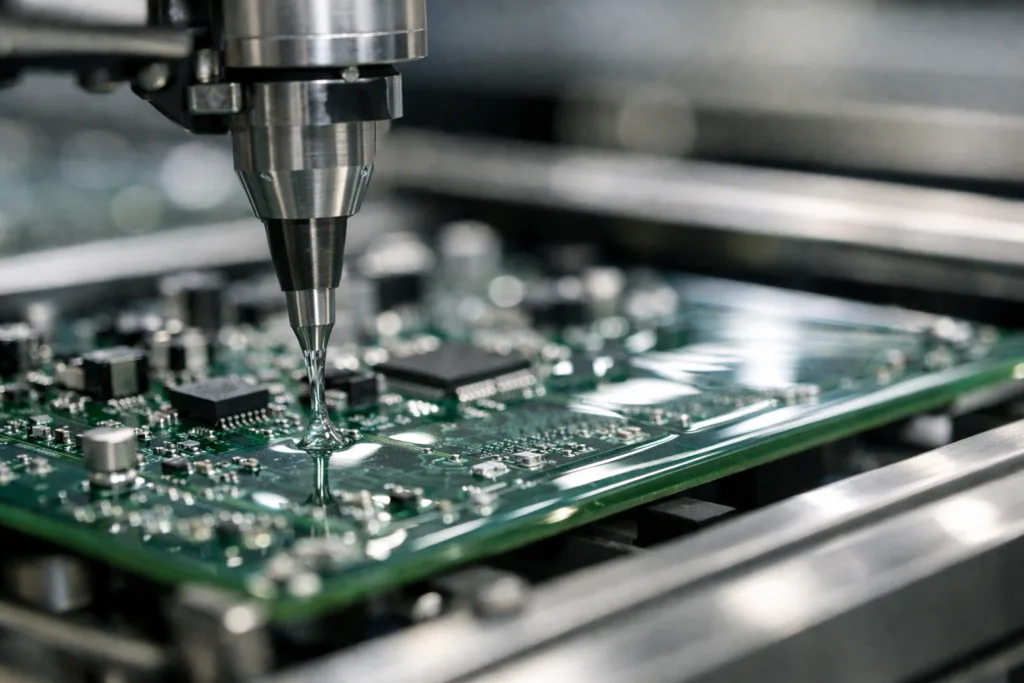

- Application: The adhesive is dispensed onto the target surfaces—options include bead, spray, slot-die, or roll coating.

- Liquid Stage: The glue remains fluid before exposure, allowing for adjustment and fixturing.

- UV Exposure: A UV lamp (typically 180–400 nm wavelength) activates the adhesive. Cure time ranges from a few seconds to several minutes (pot life and open time are short, so fast processing is key).

- Solid Stage: The adhesive hardens. Final bond strength and hardness (measured in Shore A/D) is achieved, with lap-shear values up to 15–25 MPa for engineered products.

Expert takeaway: For best results, make sure all areas receive direct UV light and are free of dust or oil. Use degrease/abrade preparation for metals and plastics or adhesion primers for tougher substrates.

Inline Quality Control

Manufacturers check cure with tack tests, adhesion peel strength (ASTM D1876), and thermal cycling. ZDS uses lot traceability and ISO 9001 protocols to ensure consistency. Many UV adhesives are formulated to meet RoHS and REACH standards, promising safe handling and low volatile organic compound (VOC) levels.

Liquid to Solid: Visualizing the Change

Before cure, UV adhesive looks like clear syrup. It can be dispensed precisely by automated machines or manually. Under UV lamp exposure, the transformation is fast—within seconds, the liquid turns into a solid bond. In some cases, you can see the adhesive flow stop and edges set as the light passes.

Key Cure Metrics

- Cure time: 3–60 seconds (depends on thickness and lamp power)

- Tg (glass transition temperature): 80–120°C typical

- Hardness: Shore D 45–85 for rigid bonds

- Viscosity: 200–3,000 cP (centipoise), controls spread and application method

UV vs. Heat and Moisture Cure Adhesives

How do UV adhesives differ from heat-cure or moisture-cure products? The answer lies in speed, control, and substrate safety.

| Feature | UV Adhesive | Heat-Cure | Moisture-Cure |

|---|---|---|---|

| Cure Trigger | Ultraviolet light | Elevated temperature | Air or ambient moisture |

| Cure Speed | Seconds to minutes | Minutes to hours | Hours to days |

| Application Control | Very high (cures only where illuminated) | Moderate | Limited |

| Best for Sensitive Materials | Yes (low thermal stress) | No (risk of heat damage) | Sometimes |

| Common Chemistries | Acrylate, epoxy, silicone | Epoxy, polyurethane | Cyanoacrylate, polyurethane, MS hybrid |

Advantages of UV Adhesives

- On-demand cure for fast assembly lines

- Reduced risk of component overheating or moisture sensitivity

- No need for ovens or climate chambers

When Not to Use UV Adhesives

- Poor light access or shadowed areas

- Opaque materials blocking UV light

- Need for bulk bonding in thick joints

Typical Industrial Applications for UV Adhesives

UV adhesives fill key roles where precision, speed, and clean processing matter. Here are common industrial scenes:

Electronics Assembly

Used to bond glass displays, seal microchips, tack wires, and create transparent covers. The low thermal load preserves sensitive sensors and keeps surface finishes pristine. ZDS supports electronics manufacturers with custom UV solutions for touch panels and camera modules.

Medical Device Manufacturing

UV adhesives form ultra-clean, biocompatible bonds for catheters, filters, and housings. Fast cure times make high-volume production possible. Most formulas pass ISO 10993 (medical biocompatibility) and FDA requirements.

Optical Products and Glass Bonding

Special UV glues bond lenses with crystal clarity, leaving invisible seams. Fast curing lets workers align components easily, then lock them in place within seconds.

Automotive Sensors and LED Modules

UV adhesives bond, seal, or fix delicate sensors to plastics and metals. Their low-outgassing properties protect optics and circuitry—critical for advanced driver-assistance (ADAS) systems. ZDS produces UV epoxies tailored for automotive requirements.

Industrial Assembly and Repair

Repairing glass, plastics, or composite items is easy with UV adhesives. Instant curing avoids downtime and supports clean, solvent-free operations.

Other Use Cases

- Bonding smartphone parts, watch crystals, and solar panels

- Fixing fiber optic cables and network connectors

- Securing small medical and lab components

What Are UV Adhesives?

UV adhesives are light-cured bonding materials that use photoinitiators to transform from liquid to solid upon exposure to ultraviolet light. This rapid curing process provides precise, strong bonds for electronics, medical devices, optics, and more. ZDS offers advanced UV adhesive systems customized for industrial and OEM production lines.

Designing with UV Adhesives: Process Guidance

For design engineers, choosing the right UV adhesive depends on substrate type, bond performance, cure speed, and application method. Here is a stepwise guidance process:

- Confirm substrates: Glass, metal, plastic, ceramic, or composite? (Some like ABS, PC, PP need corona/plasma or primer.)

- Prepare surfaces: Degrease or abrade; for hard-to-bond plastics, use adhesion promoter.

- Select chemistry: Acrylate for flexibility; epoxy for strength; silicone for movement and temperature resistance.

- Dispense precisely: Automate bead, spray, or slot-die as needed.

- Fixture parts: Use alignment tools—adhesive remains liquid until illuminated.

- Expose to UV light: Ensure direct coverage; adjust lamp wavelength and exposure for full cure.

- Verify cure: Visual tack/sheen, peel strength, and hardness—use ASTM/ISO tests where specified.

Best Practices for Production Lines

- Store adhesive in cool, dark conditions; avoid premature cure

- Use static mixers for 2K (two-component) products if needed

- Check lamp intensity regularly for quality control

- Keep documentation for compliance: SDS, batch, REACH/RoHS

- Plan for aging and thermal cycling tests if demanded by application

Future Trends in UV Adhesive Technology

Next-generation UV adhesives promise even faster cures and bonding to trickier substrates. Hybrid formulas now blend UV with secondary thermal or moisture triggers for shadowed areas. Smart polymers track cure depth and performance in real time. ZDS is developing new systems for automotive, electronics, and medical device innovation, offering fully customized solutions.

Frequently Asked Questions

How does UV adhesive curing differ from heat curing?

UV adhesives cure when exposed to ultraviolet light, allowing rapid bond development without raising temperatures. Heat-curing adhesives require ovens or hot plates, which can damage heat-sensitive components and slow production lines.

What substrates are best for using UV adhesives?

UV adhesives work best with transparent or translucent materials like glass, certain plastics (PC, PMMA), and some metals. Opaque surfaces may block UV light and prevent complete curing unless special formulas or hybrid UV/thermal systems are used.

How do I prepare surfaces for UV adhesive bonding?

Clean all surfaces thoroughly to remove oils and dust, then abrade lightly if bonding metals or hard plastics. Use adhesion promoters or primers for low surface energy plastics and ensure the area is dry and accessible to UV light.

What is the pot life of UV adhesives?

UV adhesives have an unlimited pot life before exposure to UV light, staying liquid and workable. However, once illuminated, the cure proceeds rapidly—usually in seconds to minutes—allowing precise control over assembly processes.

Are UV adhesives suitable for outdoor or high-temperature environments?

Many epoxy and silicone UV adhesives perform well outdoors and in high-temperature settings, offering excellent chemical and UV resistance. Always select a product with specified temperature and weathering ratings for your application.

Can UV adhesives bond opaque or shadowed structures?

Standard UV adhesives require direct light for curing; they struggle with opaque or shaded zones. Hybrid UV adhesives with secondary thermal or moisture cure mechanisms can bond these areas, but application design must compensate for limited accessibility.