How Adhesives Handle Fast Charging: The Science Behind Thermal Shock Resistance

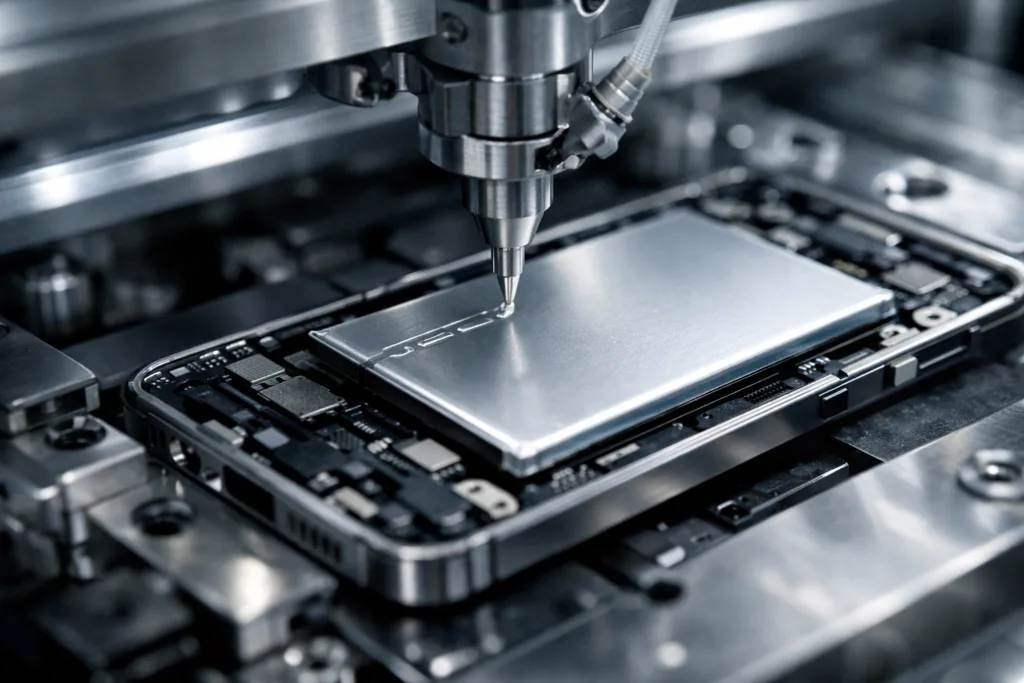

Introduction: Why Fast Charging Demands Superior Thermal Shock Resistance As fast charging cycles become the new normal for electric vehicles and battery-powered devices, the role of adhesives in thermal shock resistance has never been more critical. Thermal shock resistance: testing adhesives for fast charging cycles is at the forefront of designing batteries that last longer […]

How Adhesives Handle Fast Charging: The Science Behind Thermal Shock Resistance Read More »