RTV Silicone Adhesive Manufacturer & Custom Formulator

Neutral Cure | Acid Cure | OEM Supply | Since 2003

Looking for RTV silicone adhesive that delivers consistent bonding performance in industrial conditions? ZDS™ is a trusted RTV adhesive manufacturer based in Shenzhen, China, offering custom silicone formulations, bulk supply, and full OEM/ODM packaging solutions.

Home >> Adhesive Type >> RTV Silicone Adhesive

What Is RTV Silicone Adhesive?

RTV silicone adhesive (Room Temperature Vulcanizing) is a single- or two-component silicone system that cures at ambient temperatures, forming a durable, flexible, and weather-resistant bond.

How It Cures:

- 1-Part RTV: Cures upon contact with atmospheric moisture.

- 2-Part RTV: Requires mixing before application; offers faster, more controlled cure.

Product Series Overview

Model

Style

Curing Time

Surface Drying Time

Details

- ZDS6280

- Two-component silicone/addition potting glue

- 25 °C, RH: 50%, H

- 25 °C, RH: 50%, min

- ZDS527-H

- Two-component silicone/addition potting glue

- Curing time (25 °C, RH: 50%, H)

- Surface drying time (25 °C, RH: 50%, min)

- ZDS2680

- Two-component silicone/condensation potting glue

- 25 °C, RH: 50%, H

- 25 °C, RH: 50%, min

- ZDS2682

- Two-component silicone/condensation potting glue

- 25 °C, RH: 50%, H

- 25 °C, RH: 50%, min

Need help choosing the right adhesive?

Just share your needs with us — our experts will match you with the best solution. Click the button below to get started.

Key Features of RTV Silicone Adhesives

Customers from various sectors use our UV adhesives for applications such as:

| Property | Benefit |

| Room Temp Curing | No need for ovens or heat activation |

| Excellent Flexibility | Withstands vibration and expansion |

| High Temp Resistance | Operating range: -60°C to 250°C |

| Chemical Stability | Resistant to oils, water, solvents, ozone |

| Electrical Insulation | Ideal for electronics and LED modules |

| Substrate Versatility | Bonds glass, metal, plastic, ceramic, rubber |

Why Choose ZDS™ as Your RTV Silicone Adhesive Supplier?

🔬 Tailored Formulation Capabilities

- Acid-cure, neutral-cure, and alkoxy-cure systems

- Custom cure speed, modulus, viscosity, and flow control

- Specialized additives for thermal conductivity, UV resistance, or flame retardance

🧴 OEM & Private Label Options

- Syringes, dual cartridges, drums, or tubes

- Custom color, viscosity, or flow properties

- Fully branded packaging and technical datasheets for private label clients

📦 Flexible Supply & Export

- Bulk supply for manufacturing lines and distributors

- REACH/RoHS-compliant

- Global export capabilities and multi-language documentation

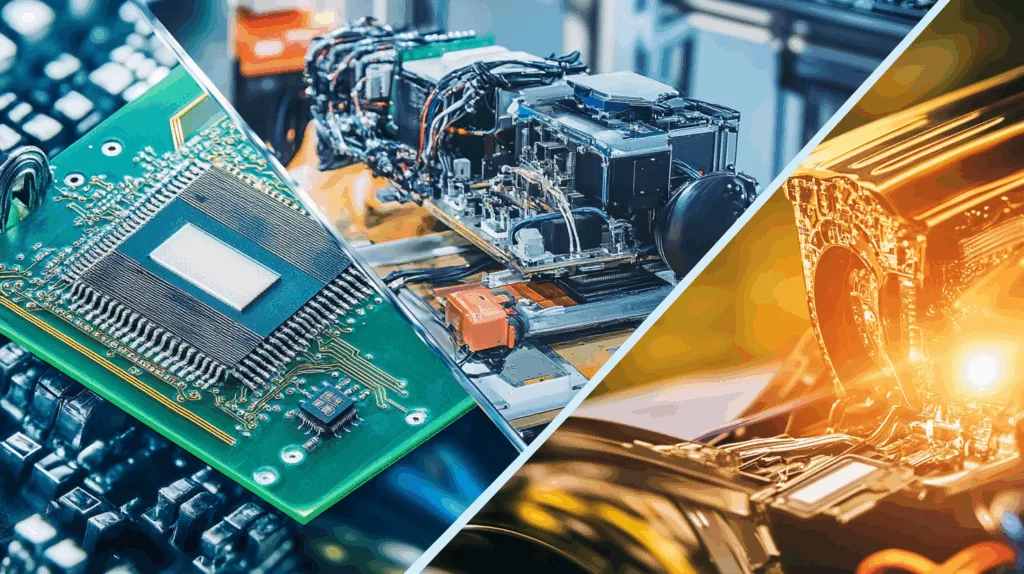

Applications of RTV Silicone Adhesives

ZDS™ RTV systems are trusted in multiple industries:

- Electronics: LED bonding, PCB encapsulation, wire insulation

- Automotive: Gasket sealing, vibration damping, weatherproofing

- Construction: HVAC seals, glass bonding, waterproof joints

- Medical Devices: Skin-safe formulations for wearables

- Appliances & Consumer Goods: Oven seals, lighting modules, plastic bonding

Frequently Asked Questions

What does RTV mean in silicone adhesives?

RTV stands for Room Temperature Vulcanizing. RTV silicone adhesives cure at ambient temperatures without external heating.

What’s the difference between acid-cure and neutral-cure RTV?

Acid-cure RTV (acetoxy) releases acetic acid during curing and may corrode metals or PCBs. Neutral-cure RTV is non-corrosive and better for electronics, sensitive materials, and enclosed spaces.

Can RTV silicone adhesive be used for electrical insulation?

Yes. ZDS™ RTV silicones are electrically insulating and commonly used in PCB encapsulation, wire sealing, and LED protection.

Do you offer OEM/ODM packaging for RTV silicone?

Yes. We provide private label packaging, custom cartridge filling, and printed labels tailored for distributors or end-product integration.

Get Your Custom Silicone Adhesive Solution Today

Industrial-Grade Silicone Adhesives—Backed by 20+ Years of R&D

Whether you’re sourcing for bulk supply, OEM/private label adhesives, or need a custom formulation, ZDS™ provides the technical expertise and manufacturing reliability you can trust.