UV Adhesive Solutions – Fast-Curing, High-Performance Adhesives for Every Industry

What Is UV Adhesive?

Key Features:

- ⚡ Fast curing in seconds

- 🌫️ Clear and bubble-free finishes

- 💪 Strong adhesion to a wide range of substrates

- 🌿 Solvent-free & low VOC

- 🔒 Excellent chemical, heat, and moisture resistance

Explore Our UV Adhesive Categories

UV Adhesive for Plastic

Designed for bonding PET, PMMA, PC, and other plastic substrates with invisible finishes and strong adhesion.

UV Adhesive for Glass & Metal

Ideal for structural and decorative applications requiring crystal-clear, durable bonds between glass and metals like aluminum or stainless steel.

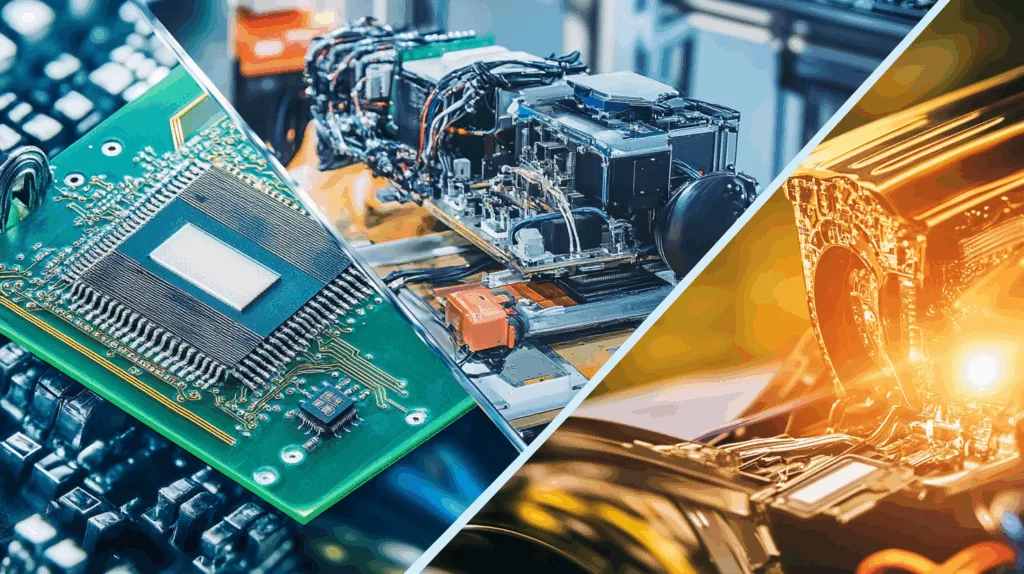

UV Adhesive for Electronics

Electrically insulating, fast-curing adhesives for wire tacking, PCB bonding, chip encapsulation, and more.

UV Adhesive for Special Industries

Custom formulations for aerospace, cleanroom assembly, renewable energy, smart textiles, and other high-performance sectors.

Model

Appearance

Viscosity /cps

Curing energy mj

Details

- ZDSCD2108204 Model lamp bead glue

- Transparent or yellowish liquid

- 3000~3400

- 400-800mj£»365 point light source

Need help choosing the right adhesive?

Just share your needs with us — our experts will match you with the best solution. Click the button below to get started.

Common Applications of UV Adhesive

- 📱 Smartphone & consumer electronics assembly

- 💡 LED & lens bonding

- 🔬 Diagnostic devices and microfluidic chips

- 🖼️ Glass art and furniture design

- 🛰 Aerospace sensors and PCB potting

- ⚡ Solar panel encapsulation

- 🛡 Vibration-resistant automotive modules

Benefits of ZDS™ UV Adhesives

✅ Fast & Efficient

Most formulas cure in 2–10 seconds under standard UV or LED lights, significantly reducing production time.

✅ Versatile Across Substrates

Bond glass, plastics, metals, ceramics, and composites with ease—perfect for hybrid material assemblies.

✅ Clean Application

Dispense accurately with minimal waste. No need for mixing or post-cleaning, ideal for automation.

✅ Strong & Durable

Resistant to vibration, impact, heat, and chemicals, ensuring reliable performance across demanding environments.

✅ Compliant & Safe

Our products meet RoHS, REACH, and ISO certifications and are manufactured under strict quality control.

What to Consider When Choosing UV Adhesive

To find the best UV adhesive for your project, consider the following:

- Materials – What are you bonding? Plastics, metals, or composites?

- Curing Equipment – Do you use UV LED (365–405nm) or mercury vapor lamps?

- Production Speed – How fast do you need the adhesive to cure?

- Certifications – Do you need biocompatibility or outgassing reports?

- Environmental Conditions – Will the bonded product face heat, UV exposure, or chemicals?

💡 If you’re unsure, contact us for expert consultation or request a free sample.

Frequently Asked Questions

How do UV adhesives work?

Do I need special equipment?

Are UV adhesives safe?

Can I request a custom formulation?

How can I get a sample?

Work with ZDS™ – Your UV Adhesive Expert

- 🔹 Expert technical support

- 🔹 Fast global shipping

- 🔹 OEM/private-label service

- 🔹 Compliance-ready formulations

- 🔹 Scalable solutions from prototyping to mass production

📩 Ready to get started?

Contact us today for technical data, samples, or quotes.