In the highly regulated world of healthcare, precision and safety are paramount—especially when it comes to assembling life-saving equipment. Medical-grade cyanoacrylate, often referred to as a fast-curing, biocompatible glue, plays a vital role in medical device manufacturing. This specialized ISO adhesive is engineered to deliver strong, sterile bonds with minimal application time, making it indispensable for modern medical technologies.

ZDS™ is a trusted adhesive manufacturer providing innovative bonding solutions, including high-performance medical-grade cyanoacrylates that meet strict biocompatibility and ISO certification requirements.

Let’s explore how medical device manufacturers are safely using this powerful adhesive to revolutionize healthcare production.

Understanding Medical-Grade Cyanoacrylate

Medical-grade cyanoacrylate is a quick-bonding adhesive specifically formulated for use in healthcare applications. Unlike standard superglues, it undergoes rigorous purification and testing to meet ISO 10993 standards for biocompatibility.

Key Characteristics:

-

Fast curing at room temperature

-

Low toxicity and tissue reactivity

-

Excellent adhesion to plastics, metals, and rubber

-

Sterilization-compatible (ETO, gamma, autoclave depending on formulation)

These properties make medical-grade cyanoacrylate a go-to choice for everything from disposable syringes to catheter assemblies and even wound closure systems.

Why Biocompatibility Matters in Adhesives

Biocompatible glue is essential in medical applications because it must not cause cytotoxicity, irritation, or sensitization when in contact with human tissues or fluids.

ISO Standards and Testing

To be classified as a medical-grade ISO adhesive, products must pass ISO 10993 tests for:

-

Cytotoxicity

-

Sensitization

-

Irritation or intracutaneous reactivity

ZDS™ ensures all its medical adhesives meet or exceed these biocompatibility requirements through advanced formulation and stringent in-house testing.

Applications in Medical Device Manufacturing

Disposable Medical Devices

Medical-grade cyanoacrylate is widely used in the production of disposable items like:

-

IV tubing sets

-

Diagnostic test kits

-

Needle assemblies

Its fast setting time allows for high-throughput manufacturing without compromising bond integrity.

Surgical Instruments and Implant Assemblies

In more complex assemblies, especially those involving dissimilar materials or small geometries, this adhesive provides the precision and strength required.

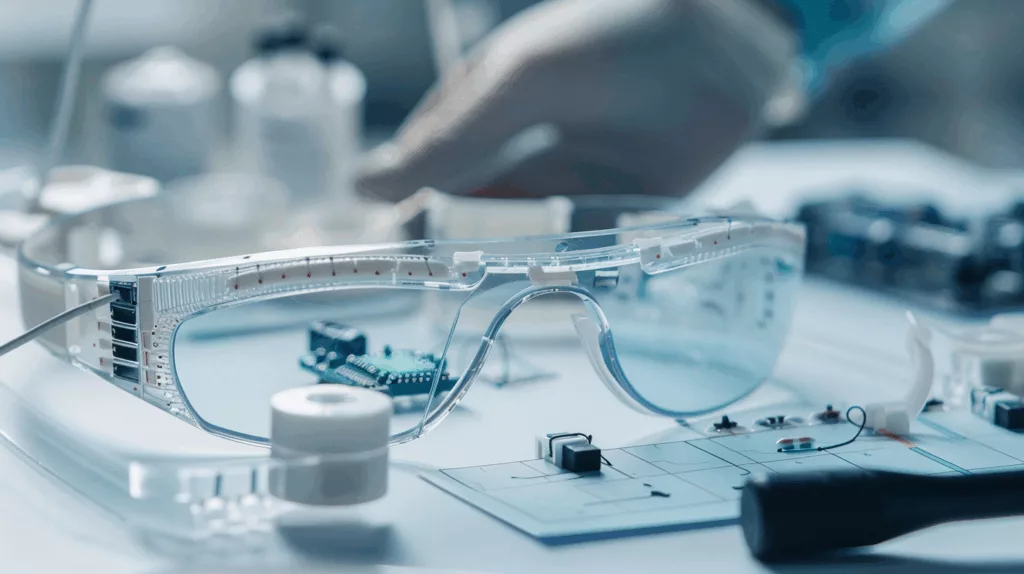

Electronics in Wearable Medical Devices

The glue’s compatibility with plastics and metals makes it ideal for bonding components in portable or wearable medical devices that must remain intact during extended use.

Best Practices for Safe Use

While medical-grade cyanoacrylate offers many advantages, its safe use requires adherence to specific protocols.

1. Controlled Dispensing

Using micro-dispensing systems ensures precision in glue application, minimizing excess and reducing exposure risks.

2. Cleanroom Conditions

Manufacturers often apply cyanoacrylate adhesives in ISO Class 7 or better cleanrooms to prevent contamination.

3. Employee Safety Training

Operators must be trained in the proper handling of cyanoacrylate adhesives, including eye and skin protection and fume control, especially in high-volume environments.

4. Compatibility Testing

Before full-scale production, compatibility testing with device materials is critical to prevent bond failure or chemical interaction over time.

Future Trends in Medical Adhesive Technology

As devices become smaller and more complex, the role of specialized adhesives continues to grow. Key trends include:

-

UV-curable medical cyanoacrylates for faster processing

-

Dual-cure systems that combine cyanoacrylate and epoxy for added durability

-

Bioresorbable adhesives for temporary implants

ZDS™ is at the forefront of these innovations, helping manufacturers stay ahead of evolving medical demands.

FAQs

What makes an adhesive “medical-grade”?

Medical-grade adhesives meet strict ISO 10993 biocompatibility requirements and are produced in controlled environments to ensure sterility and safety.

Can medical-grade cyanoacrylate be used internally?

Only specific formulations intended for internal use should be applied. These are typically used for topical skin bonding and not for deep tissue unless explicitly tested and approved.

Is cyanoacrylate glue safe for wearable medical devices?

Yes, when properly formulated, it can bond components of wearable medical electronics without compromising skin safety or mechanical integrity.

Ready to Bond with Confidence?

Whether you’re designing a wearable monitor, surgical instrument, or single-use diagnostic kit, choosing the right adhesive is critical. Medical-grade cyanoacrylate adhesives offer unmatched speed, safety, and reliability—especially when formulated by experts like ZDS™.

Partner with ZDS™ today to ensure your medical device adhesives meet the highest standards for performance and biocompatibility.