Introduction: Camera Lens Dust Sealing—Precision Matters

Photographers—from enthusiasts to full-time professionals—know the heartbreak of discovering dust particles inside an expensive camera lens. Modern camera designs rely on camera lens dust sealing: precision gaskets to create a barrier against dust, moisture, and environmental stressors. These components are not just passive parts; they’re high-performance solutions engineered to maximize lens durability, maintain image quality, and minimize maintenance interruptions.

Protecting optics from contaminants is a science. As lens assemblies become smaller, more complex, and more digital, the need for robust, precision-engineered gaskets is now critical. In this comprehensive guide, we explore how these gaskets work, what goes into their manufacture, best practices for maintaining lens seals, and practical ways you can keep your camera performing at its peak.

What Are Precision Gaskets for Camera Lens Dust Sealing?

Precision gaskets are soft, engineered sealing components designed to tightly fit between lens housing parts. Their primary job: to create dust-tight, and often moisture-resistant, barriers that protect sensitive internal optics and electronics. In the context of camera lens dust sealing, this means keeping out particles that could cloud your shots or damage complex electronics—whether you’re shooting on a crowded street or hiking in the wild.

How Precision Gaskets Protect Camera Lenses from Dust

When installed, precision gaskets act as physical traps for airborne particulates. A well-fitted seal blocks dust, sand, pollen—even microscopic fibers—from entering the lens barrel. With most modern cameras, these seals surround moving and stationary parts—like zoom mechanisms, lens mounts, and even electronic shutters.

| Component | Sealing Function | Typical Material |

|---|---|---|

| Lens Barrel | Prevents dust around zoom/focus | Silicone, EPDM |

| Lens Mount | Seals interface w/ camera body | Polyurethane, TPE |

| Control Rings | Seals mechanical controls | Foam rubber, silicone |

For high-durability commercial seals, manufacturers sometimes use custom polyurethane potting glues, which combine elastic rebound with strong environmental resistance.

Why Dust Sealing Is Essential for Lens Performance

Unsealed lenses can accumulate dust inside the optics, leading to blurry images, sensor interference, and expensive repairs. Over time, dust can degrade coatings, jam moving rings, and reduce the value of professional gear. Proper dust sealing extends the usable life of a lens and ensures peak performance, especially in outdoor and industrial environments.

- Image Quality: Fewer internal particles mean sharper, clearer photos.

- Mechanical Reliability: Reduces wear and tear on controls and internal mechanisms.

- Moisture Resistance: Many dust seals also offer water barrier properties.

For added moisture resistance, use of waterproof bonding adhesives has set new standards in microelectronics, further protecting inner lens assemblies.

Precision Gasket Materials: What Makes the Difference?

Not all seals are created equal. Materials used in precision gaskets for camera lenses must be both flexible and resilient—not reacting with lens coatings or camera plastics. The most common materials are:

- Silicone Rubber: Flexible, temperature- and UV-resistant, ideal for lens barrels

- EPDM (Ethylene Propylene Diene Monomer): Excellent for outdoor/cold environments

- Polyurethane: Durable, bonds well, good for mounts and moving interfaces

- Thermoplastic Elastomer (TPE): Soft-touch, customizable shapes, extra flexibility

Choosing the right material comes down to the application—whether you need chemical resistance, UV protection, or maximum longevity. Manufacturing partners like industrial adhesive experts frequently help engineers select and test new material blends for optimal results.

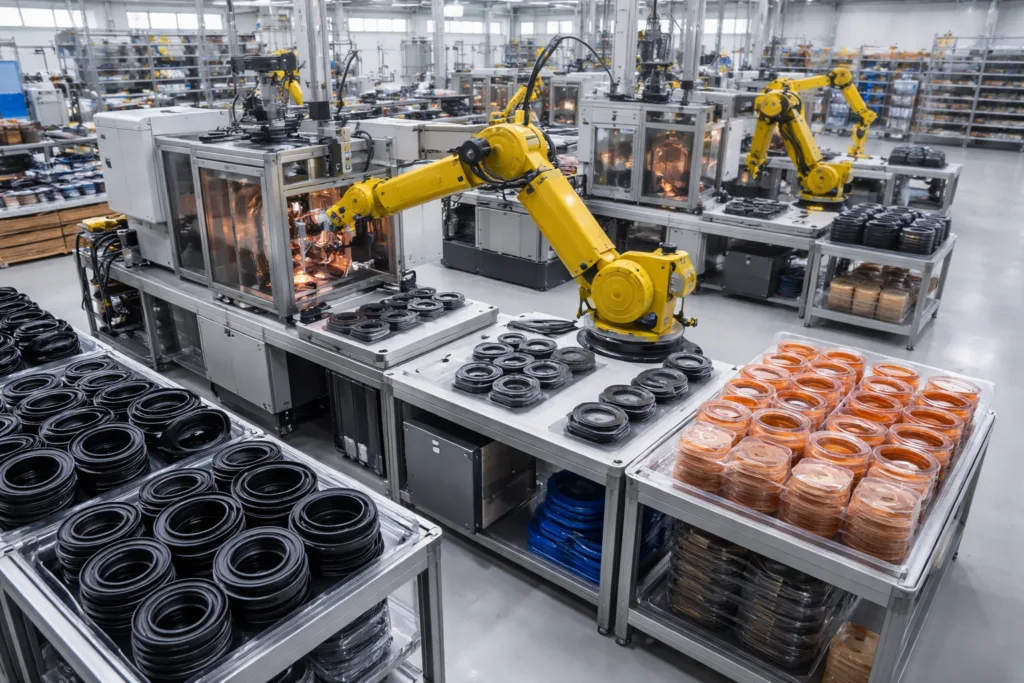

Manufacturing Processes for High-Precision Gaskets

Creating high-performing dust seals for cameras requires advanced tooling and process control. Here’s how modern manufacturers achieve consistency:

- Injection Molding: Allows for tight tolerances, consistent quality, and fine features

- Die Cutting: Used for foam or rubber flat gaskets in lens rings

- Extrusion: Suits long, continuous seals for lens barrels

- Laser Cutting: Precise, low-heat processing for sensitive materials

From the viewpoint of ZDS Adhesive, an industrial adhesive manufacturer, the choice of process often depends on the required pot life and open time of the sealing adhesive, as well as how quickly the gasket needs to fixture without distortions. This makes dialed-in process control absolutely essential.

Technological Innovations in Camera Lens Dust Sealing: Precision Gaskets

The latest camera lens seals incorporate nanotechnology coatings, multi-layered seal profiles (with both dust and water resistance features), and adhesive-backed gaskets for tool-less installation. Automated assembly lines can deploy gaskets with pinpoint accuracy, leveraging high-transparency UV-curing glues for invisible bonds. Some next-gen gaskets even feature RFID tracking, allowing for lifecycle monitoring and maintenance prediction.

Types of Precision Gaskets in Camera Lens Dust Sealing

Gaskets for cameras aren’t one-size-fits-all. Common types include:

- O-Rings: Circular elastomers used in lens barrels and mounts

- Flat/Ring Gaskets: Die-cut shapes for control rings and interface covers

- Custom Molded Seals: Shaped for complex lens assemblies

- Adhesive-Backed Seals: Pealable, easy to install, used in DIY repairs

Comparison Table: Gasket Types and Their Effectiveness

| Gasket Type | Dust Protection | Moisture Protection | Durability |

|---|---|---|---|

| O-Ring (Silicone) | High | Medium | Long |

| Flat Gasket (EPDM) | Medium | Low | Medium |

| Polyurethane Molded | High | High | Very Long |

| Adhesive-Backed Foam | Medium | Low | Short |

How to Inspect Camera Lens Dust Seals

Routine inspection is essential for camera longevity:

- Check for visible cracks, deformation, or discoloration on gaskets.

- Gently blow compressed air into seams and observe if dust escapes.

- Use a soft brush or lens cleaning cloth to occasionally remove external debris.

- Inspect around moving rings—these areas are most vulnerable.

Common Failure Modes in Precision Gaskets

Despite advances, gaskets fail due to aging, UV, chemical exposure, or improper installation:

- Compression Set: Gasket permanently flattens & loses elasticity.

- Chemical Degradation: Reaction with cleaning agents or lens coatings.

- Cracking/Crazing: Driven by extreme temperatures or sunlight.

- Misalignment: Poor assembly can cause early leaks.

Real-World Scenarios: Precision Gasket Performance

Consider an outdoor photographer in a desert: fine sand seeks out the tiniest gaps in lens assemblies. Precision gaskets here must combine dust filtration with flexibility to handle wide temperature swings. For underwater housing, the need shifts to absolute moisture barriers—often combining several layers of silicone and polyurethane, plus sealant adhesives that edge out water molecules. In each case, effective dust sealing means controlled lens performance and minimal downtime.

Maintaining and Extending the Life of Lens Seals

Longevity tips:

- Store cameras in a dry, dust-free case with silica gel bags.

- Avoid exposing lenses to harsh sunlight for long periods.

- Use manufacturer-approved cleaning solutions to avoid chemical reactions.

- Replace worn seals—don’t wait for major failures.

- Document maintenance cycles for professional or studio gear.

Precision Gaskets in Consumer vs. Professional Camera Systems

The demands differ. In consumer digital cameras, seals are thinner, often designed for light dust resistance. Professional lenses use thicker, often multi-layered seals rated for harsh environments and frequent use. Ultimately, professional systems feature modular seals—easy to replace, accessible for cleaning, and tested for humidity cycling and vibration.

Technological Advances Driving Next-Gen Dust Sealing

Several factors fuel new dust sealing methods in 2026:

- Nano-Particle Resistant Coatings: Prevent ultra-fine dust adhesion.

- Hybrid Gasket/Sealant Designs: Bonded layers for dual dust–moisture protection.

- Automated Lifecycle Monitoring: RFID-tracked seals for proactive maintenance.

- Tool-Free Installation: Peel-and-stick gaskets paired with quick-cure adhesives.

Eco-Friendly and Sustainable Gasket Materials

Environmental awareness is changing seal design. Manufacturers now experiment with recyclable elastomers and bio-based polyurethane blends, aiming for low-energy processes and minimal waste. This reduces both production cost and the ecological footprint—especially important for high-volume camera production.

Precision Gasket Quality Standards and Testing

Rigorous testing ensures gasket reliability:

- Dust Ingress Rating (IP Scoring): Measures dust-tightness (IP5x, IP6x, etc.)

- Thermal Cycling: Simulates expansion/contraction over temperature swings

- Humidity Aging: Assesses moisture seal durability over time

- Lap Shear, Peel, and Compression Tests: Ensures mechanical resilience

Partnering with experienced adhesive and gasket suppliers, such as ZDS Adhesive, often brings expertise in custom testing, real-world qualification, and accelerated lifecycle protocols.

Selecting the Best Dust Sealing Solution for Your Camera

Choose based on use case (outdoor, studio, travel), lens compatibility, and available maintenance. For new builds or restorations, consult material compatibility charts and professional reviews. For advanced performance standards, prioritize multi-layered polyurethane seals or custom-molded silicone rings—these excel under heavy use and environmental extremes.

Troubleshooting Camera Lens Dust Sealing Problems

If you notice dust inside your lens, inspect all gaskets, replace any that appear damaged, and ask a technician for support when needed. Use soft brushes and air blowers before reassembling parts. If moisture is also present, a deeper professional cleaning may be needed—especially if signs of corrosion are visible.

Camera Lens Dust Sealing: Precision Gaskets

At its core, camera lens dust sealing with precision gaskets is a blend of science and hands-on engineering. As camera design evolves, so do the materials and processes behind high-performance lens seals. With proper selection, use, and maintenance of these components, photographers gain reliability, longer service cycles, and confidence—no matter where their creative work takes them.

Conclusion: Maximizing Lens Longevity with Precision Dust Sealing

The evolution of camera lens dust sealing, powered by precision gaskets, keeps modern photography gear functioning at its best. By understanding your camera’s sealing components, matching use-case to gasket type, and investing in smart maintenance, you safeguard against failures that could jeopardize your creativity or professional output. The latest manufacturing and adhesive technologies—like advanced polyurethane and hybrid seals—set new standards for protection. Looking forward, expect smarter, more adaptable dust sealing solutions built to stand up to real-world challenges.

Frequently Asked Questions

How often should I inspect or replace my camera lens gaskets?

Inspection is recommended each year for heavy use, or with noticeable wear. Replace seals if any cracks, flattening, or discoloration appears.

Can precision gaskets protect against both dust and moisture?

Yes! Modern precision gaskets can deliver dust tightness and some moisture resistance, especially silicone and polyurethane-based designs.

Does using non-approved cleaning chemicals damage lens seals?

Absolutely. Non-approved or harsh cleaners can break down gasket materials, leading to early failure and dust access. Always use manufacturer-recommended solutions.

What’s the simplest way to test for dust leaks in my lens?

Use a bright light and compressed air around seams. If you see dust movement, resealing or seal replacement may be needed.

Are professional lens gaskets much better than those in consumer cameras?

Professional gaskets tend to be thicker, multi-layered, and tailored for extreme use, offering better dust and moisture protection compared to consumer versions.

Can I replace camera lens gaskets myself, or should I seek professional help?

Basic adhesive-backed gaskets can be replaced DIY, but complex or molded seals are best handled by qualified technicians to avoid damage.