Introduction to Latent Curing Agents in Single Component Epoxies

Single component epoxies have revolutionized industrial bonding and assembly, offering streamlined application and dependable performance. At the heart of this innovation are latent curing agents, specialist compounds that enable extended shelf life and remove the need for complex mixing—including in environments ranging from automotive production to precision electronics. In 2026, their role in advanced manufacturing has become even clearer: latent curing agents are the quiet heroes behind robust, reliable bonds when simplicity and consistency are critical.

What Are Latent Curing Agents?

Latent curing agents are special chemicals inside single component epoxy adhesives that remain inactive at room temperature. They only trigger the curing process when exposed to defined stimuli, like heat or UV light. This delay is crucial—it prevents premature hardening and lets manufacturers store, transport, and use these adhesives over long periods with no risk of waste or failure.

Chemical Mechanisms Behind Latency

Most latent curing agents are formulated to harness temperature sensitivity or chemical activation. Common classes include:

- Amines protected by blocking groups

- Dicyandiamide (DICY)

- Anhydrides

- Imidazoles and their derivatives

- Microencapsulated hardeners

The core mechanism centers on activation energy: latent agents remain inert under ambient conditions. On heating to a specific threshold (often 80–150°C), they become reactive, initiating cross-linking and the characteristic strength of epoxy networks.

How Latent Curing Agents Enable Prolonged Shelf Life

Shelf stability is a standout advantage of single component epoxies harnessing latent curing agents. Adhesive manufacturers calibrate these systems so that storage at 10–25°C maintains full reactivity for months, even years—enabling strategic inventory management and reducing expired product waste.

For instance, dicyandiamide (DICY) is widely used because it resists reaction with epoxy resins until heated above 120°C, ensuring robust shelf life with predictable cure when needed.

Comparison: Latent vs. Conventional Curing Agents

| Feature | Latent Curing Agents | Conventional Curing Agents |

|---|---|---|

| Shelf Life | 6–24 months | 1–6 months |

| Mixing Requirement | None (pre-mixed) | Manual mixing needed |

| Activation | Heat/chemical/light | Ambient or low heat |

| Waste Risk | Low | High (premature cure) |

| Application Simplicity | High | Medium/Low |

Advantages over Traditional Curing Agents

The use of latent curing agents in single component epoxies brings tangible benefits for all levels of manufacturing:

- Extended Pot Life: Less product wasted, improved cost efficiency

- Process Simplification: No mixing errors, single step application

- Precise Process Control: Cure can be timed with heat or other stimuli

- Consistent Quality: Each batch is uniform, minimizing variability

- Reduced Health Risks: Limited exposure to raw chemical hardeners

As a result, industries like automotive, marine, and electronics increasingly specify latent-cure epoxies for sensitive, high-value assembly tasks. For deeper technical comparisons, check out ZDS Chemical’s epoxy adhesive solutions.

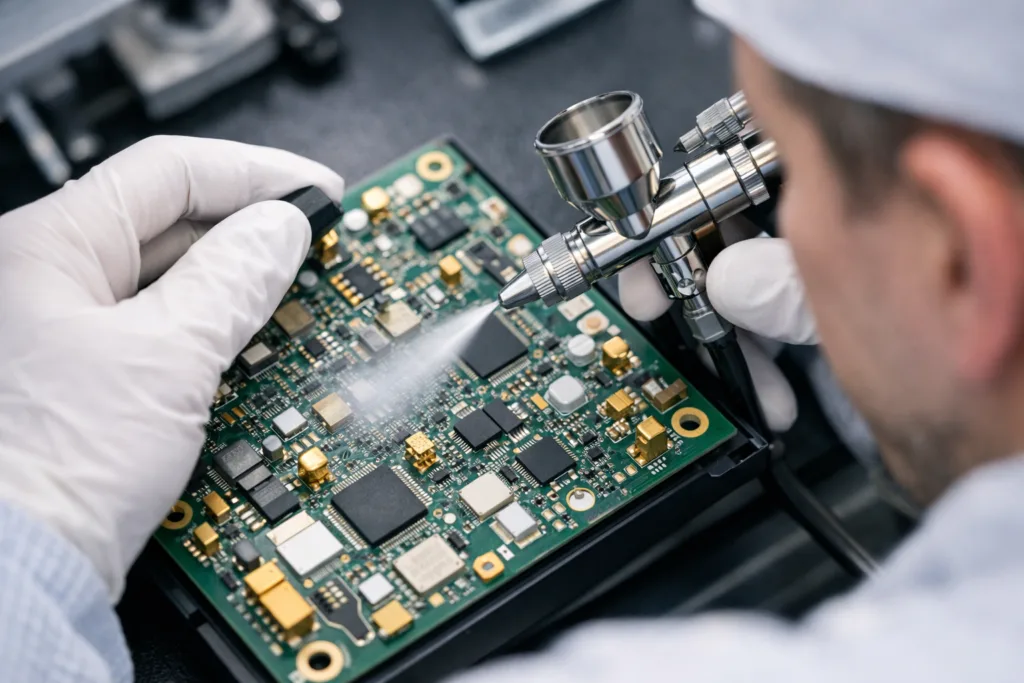

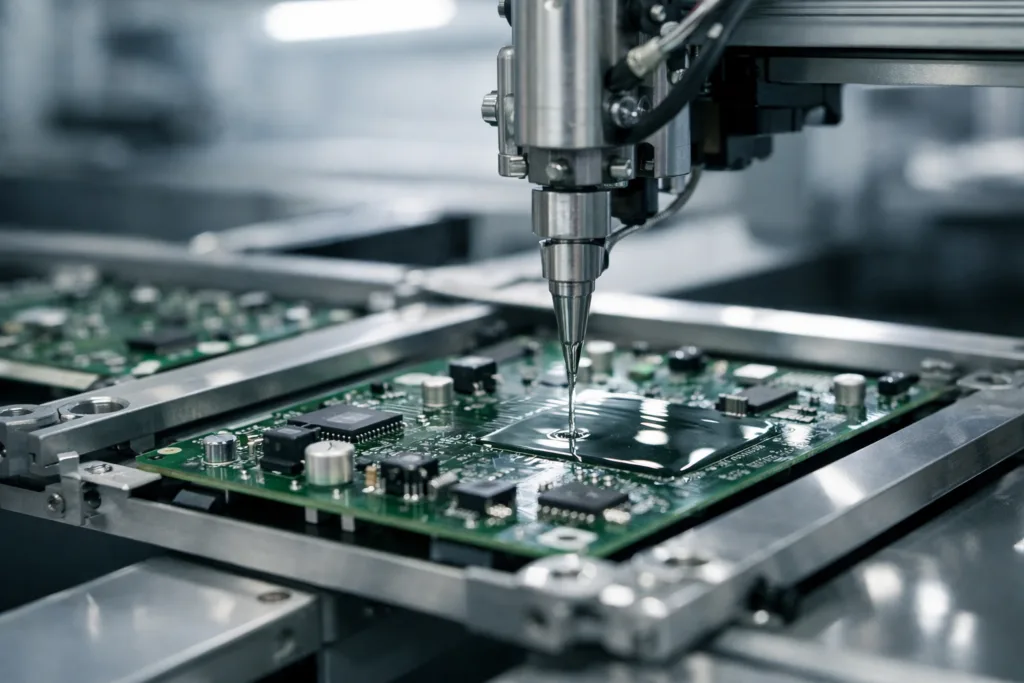

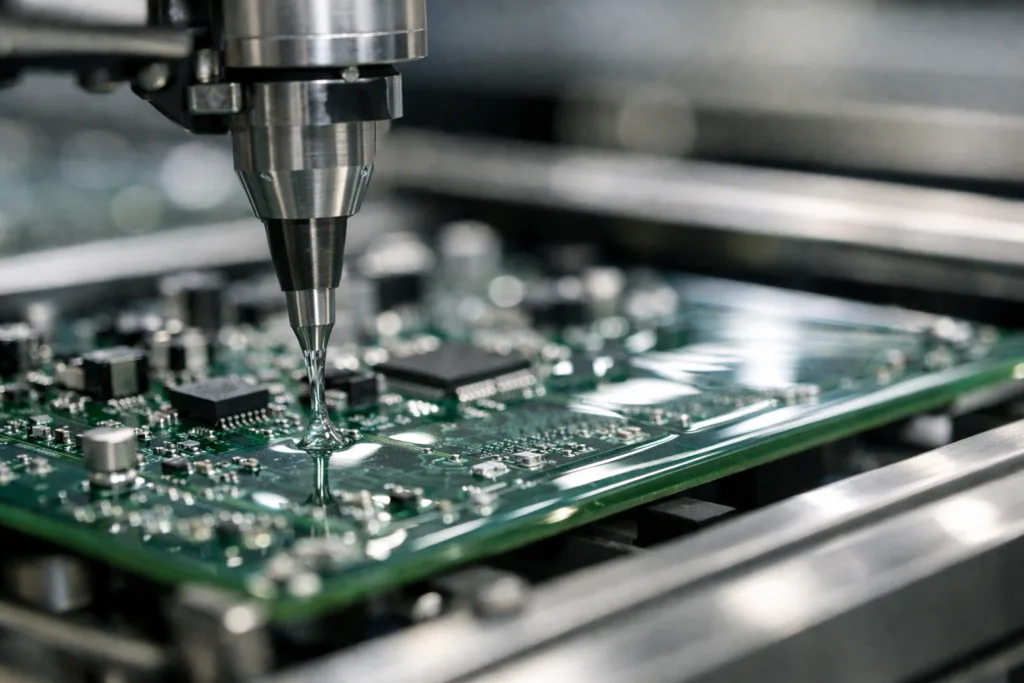

Simplifying Application Processes

Single component epoxies enhanced by latent curing agents streamline manual and automated workflows. Technicians simply dispense, assemble, and heat cure—removing mix-ratio uncertainties or pot life calculations. This approach supports robotic lines and high-throughput environments, where speed and accuracy matter.

Case Study: Automotive Body Bonding

Modern automotive production relies on structural adhesives for robustness and crash safety. Using single component, latent-cure epoxies means panels are prebonded and only fully hardened during paint bake cycles, perfectly matching body shop processes. For more applications in automotive, see automotive body adhesive solutions.

Chemical Mechanisms: How Latent Curing Agents Work

The science behind latency centers on molecular structure and activation energy. For example, protected amines must shed their blocking group, usually under heat. Dicyandiamide, an ultra-popular solid hardener, remains stable until heated, then reacts with epoxy groups to create strong and durable bonds. Other novel agents—like microencapsulated imidazoles—use barrier coatings that break only under specific conditions, extending shelf stability even further.

Activation Triggers: Heat, Light, and Chemical

- Thermal Activation: Curing starts at set temperature (80–150°C typical)

- Chemical Activation: Reaction induced by mixing with additional material

- Photo-Activation: Initiated by UV or visible light, mostly for specialty electronics

Industrial Applications

Automotive

Latent curing agents are key in assembling car body panels, glass, and trim. Their delayed cure matches bake oven processes and enables robust, vibration-resistant bonding.

Aerospace

Aircraft makers favor latent-cure epoxies for composite assembly and critical fastener insulation, where precision and shelf stability are essential.

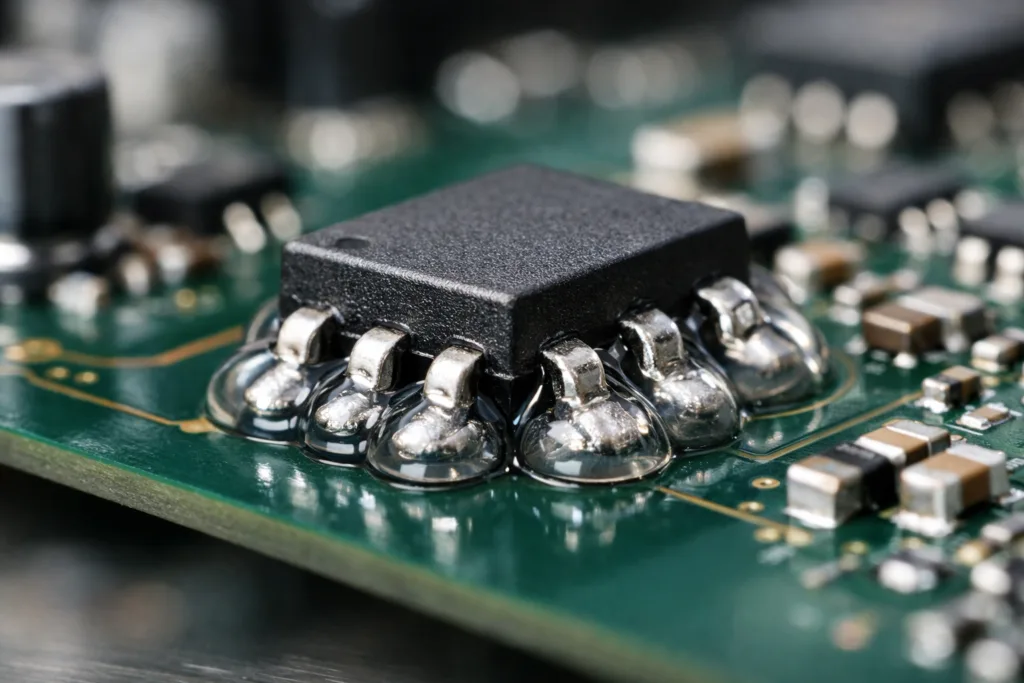

Electronics

Latent-cure adhesives seal PCBs, sensors, and connectors, providing moisture resistance and fine-tuned processing windows. For demanding dielectric applications, explore related techniques in low dielectric constant coatings for 5G/RF PCBs.

Marine and Energy

Single component epoxies with latent hardeners are widely used in shipbuilding and energy systems, thanks to weather resistance and assembly simplicity.

Performance Insights: Mechanical and Thermal Properties

The true test of any adhesive lies in its performance. Latent curing agents ensure that single component epoxies reach optimal strength and stability only after activation, matching or even surpassing traditional two-part systems in lap shear, peel, and impact resistance. The thermal cure profile is predictable, enabling automated control in factory settings.

Testing Methods and Quality Control

- Lap shear tests for joint strength

- Peel strength for multi-material assemblies

- Thermal cycling/humidity aging for electronics

- Chemical exposure for energy storage and marine applications

Limitations and Challenges

While latent-cure epoxies offer dramatic advantages, some limitations persist:

- Requirement for heat or specialized activation equipment

- Maximum cure temperature constraints in sensitive assemblies

- Potential for shelf life reduction if storage conditions vary

For battery and electronics potting, consider alternatives and compare with polyurethane systems found in silicone vs. polyurethane potting compounds for battery modules.

Selecting the Right Latent Curing Agent

The selection process should account for substrate type, final application environment, fixture time, and cure schedule. From an application engineer’s perspective at ZDS Adhesive, an industrial adhesive manufacturer, the best-fit agent depends on:

- Open time vs. cure schedule (fast or slow, batch or continuous)

- Bond strength demanded under load (shear, peel, impact)

- Moisture resistance and chemical compatibility

- Thermal activation constraints of customer processes

Reference supplier technical data, run small-scale production tests, and always screen for changes in storage or cure performance.

Case Studies: Success in Automotive and Electronics

Automotive Assembly: A major EV manufacturer shifted to a dicyandiamide-based epoxy for glass bonding. The change streamlined logistics and reduced waste—shelf life exceeded 12 months, and cure matched existing paint oven cycles.

PCB Potting: An electronics OEM used microencapsulated imidazole curing agents for PCB underfill in smart devices. They achieved consistent insulation and moisture protection, with cure timings aligned to wave soldering.

Environmental and Safety Considerations

Latent curing agents, by minimizing manual mixing of hazardous chemicals, help lower operator risk. Many formulations are free of solvents and halogens, reducing workplace exposure and benefiting environmental sustainability in 2026.

Future Directions in Latent Curing Technology

In 2026, industry trends focus on dual-cure latent agents, which combine thermal and UV activation for ultra-fast processing. Advances also include self-healing microcapsules and customized latency for smart assembly lines. New regulatory and green chemistry standards are pushing innovation toward even safer, lower VOC options for epoxies in high-value applications.

Latent Curing Agents in Single Component Epoxies

Manufacturers searching for highly reliable bonding solutions will increasingly specify latent curing agents for critical applications in automotive, electronics, and aerospace. They offer not only convenience and extended shelf life, but also precision, process control, and long-term durability. Choosing the right system depends on understanding the activation mechanism, final performance requirements, and integration with manufacturing schedules.

Conclusion

Latent curing agents have transformed single component epoxies into adaptable, high-performance adhesives that underpin progress in assembly, electronics, and beyond. Their unique chemistry enables storage stability, flexibility in application, and tailored activation—turning technical challenges into manageable steps. As new latent technologies emerge and industries adopt even stricter production requirements, these adhesives stand ready to support innovation far into the future.

Frequently Asked Questions

How do latent curing agents improve shelf life in epoxies?

Latent curing agents remain inactive until triggered by heat or other stimuli, preventing premature hardening and allowing adhesives to be stored for months or even years.

What industries benefit most from single component epoxies?

Automotive, aerospace, electronics, and marine sectors use single component, latent-cured epoxies for reliable assembly, simplified workflows, and consistency.

Can latent curing agents be activated without heat?

Some are designed for chemical or light activation, though most rely on thermal activation for predictable and controlled curing in industrial processes.

Do latent curing agents impact final bond strength?

When correctly activated, latent curing agents provide bond strength comparable to or exceeding traditional two-part epoxies, with superior process control.

How do I select the right latent curing agent?

Consider substrate, application environment, activation method, and technical data. Small-scale testing and consultation with the supplier are advisable.

Are latent curing agents environmentally friendly?

Modern formulations often reduce hazardous chemicals, support solvent-free processes, and meet stricter environmental standards for 2026 and beyond.