Introduction: Free Radical vs. Cationic Curing – UV Mechanisms Explained

UV curing is transforming industrial manufacturing, especially where speed, reliability, and quality are essential—like in metal product applications. Understanding the difference between free radical curing and cationic curing is critical when choosing adhesives and coatings for metals. Both processes have unique mechanisms influenced by ultraviolet light, but they result in different chemical, mechanical, and end-use properties. Let’s dive into how each works, explore their benefits and limitations, and see how they impact real-world manufacturing, particularly for metal components.

The Basics: What Is UV Curing?

UV curing uses ultraviolet light to trigger a chemical reaction in special resins or adhesives, converting liquid formulations into hard, durable solids within seconds. Instead of relying on heat or air-drying, UV light activates photoinitiators that start the process. This approach offers unmatched speed, precision, and energy efficiency, making it a popular choice for high-volume production lines.

How Does Free Radical Curing Work?

Free radical curing involves acrylate monomers and a photoinitiator. When exposed to UV light, the photoinitiator splits to produce highly reactive fragments—”free radicals.” These rapidly attack the double bonds in monomers, creating polymer chains. The reaction proceeds quickly, forming a tough, crosslinked network that defines the finished adhesive or coating.

How Does Cationic Curing Work?

Cationic curing is sparked by UV-activated photoinitiators too, but it generates strong acids instead of free radicals. These acids open up (“unzip”) epoxy or vinyl ether rings within the formulation, starting a chain reaction of linking molecules. The result is a stable, often more flexible polymer, created with less sensitivity to air and moisture than free radical systems.

Chemical Processes: Step-by-Step Comparison

| Aspect | Free Radical Curing | Cationic Curing |

|---|---|---|

| Resin Types | Acrylates, methacrylates | Epoxies, vinyl ethers |

| Initiator | Photoinitiator → free radical | Photoinitiator → acid (cation) |

| Reaction Start | UV breaks initiator | UV creates acid via initiator |

| Propagation | Polymerizes double bonds | Opens epoxy/vinyl ether rings |

| Termination | Oxygen or inhibitor | Moisture or base neutralization |

Advantages of Free Radical Curing

- Extremely fast curing—often seconds

- Compatible with a wide range of coatings and inks

- Cost-effective and easy to formulate

- Excellent for rigid, clear, and decorative finishes

Industrial adhesives using this mechanism, such as certain UV adhesives, are available in various strengths and viscosities to suit metal, plastic, and composite assembly lines.

Disadvantages of Free Radical Curing

- Can be inhibited by oxygen at the surface, causing incomplete curing or tackiness

- Not ideal for thicker or bulk applications due to limited UV light penetration

- Sensitive to contaminants like moisture and residual solvents

Advantages of Cationic Curing

- Resistant to oxygen inhibition—surface cures evenly

- Cures continue even after removing UV exposure (“dark cure”)

- Produces flexible, chemical- and heat-resistant bonds

- Excellent adhesion to challenging substrates like metals and glass

Disadvantages of Cationic Curing

- Typically slower than free radical systems due to ongoing polymerization

- Sensitive to water and basic (alkaline) contamination

- Raw material cost is slightly higher

Oxygen Inhibition: A Key Difference

Free radical systems often struggle with oxygen at the surface (air acts as a terminator), which can cause sticky or under-cured coatings. Cationic systems cure right through to the surface because oxygen doesn’t stop acid-driven reactions. Manufacturers may use inert gas blankets or special formulations to limit oxygen problems in free radical UV adhesives.

Substrate Compatibility for Metal Applications

Both curing methods are used for bonding and coating metals, but there are important distinctions:

- Free radical adhesives usually bond best to ferrous metals (steel, iron) and anodized surfaces.

- Cationic systems offer top performance on aluminum, copper, and non-anodized materials prone to corrosion or oxidization.

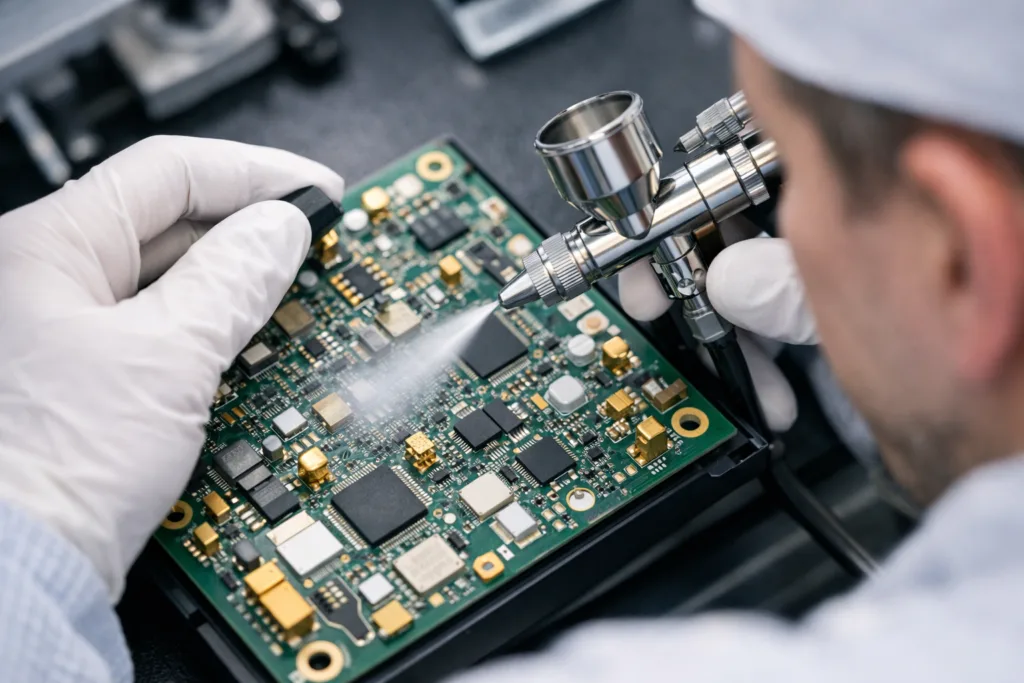

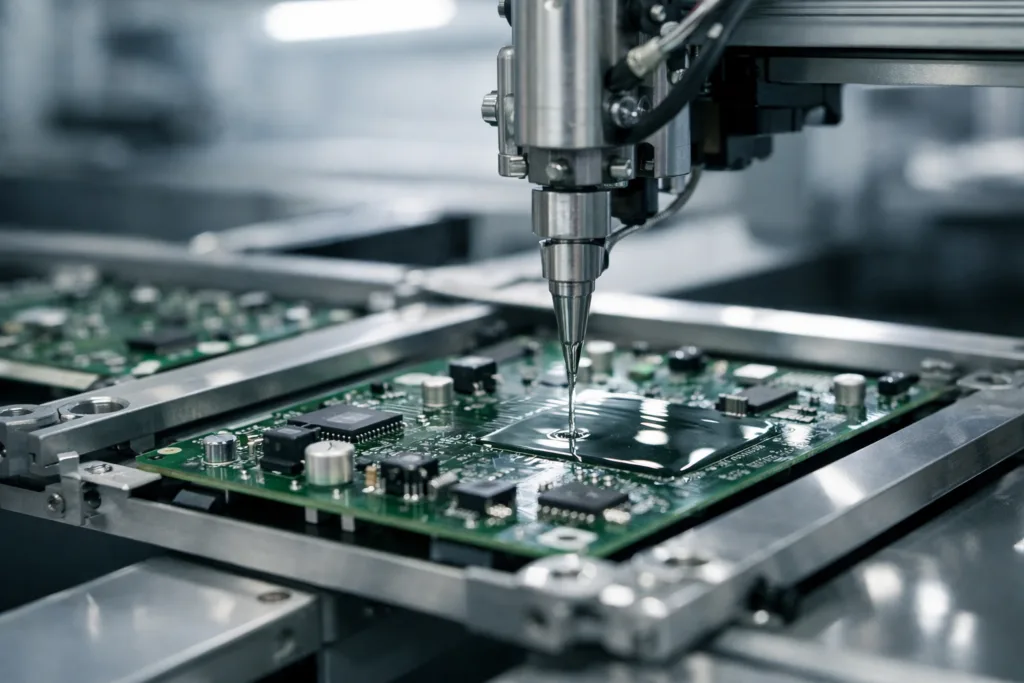

Critical Applications in Metal Product Manufacturing

Industries such as automotive, electronics, and appliance manufacturing rely on these UV curing systems for:

- Protective clear coats on steel and aluminum parts

- Adhesive assembly of sensors, housings, or trim parts

- Decorative finishes (mirror-like coatings, color effects)

- Rapid “snap” fixturing in multi-step assemblies

For specialty assembly needs, many turn to modern industrial adhesives; the metal glue manufacturers section is a useful resource to see the range of solutions available for challenging substrates.

Coating Properties: Finish, Durability, and Performance

How do these mechanisms affect final product quality?

- Free radical-cured coatings: offer high gloss, abrasion resistance, and rigidity

- Cationic-cured coatings: bring superior chemical resistance, flexibility, and improved weathering performance

The right choice depends on whether you need a tough, glossy exterior or a flexible, corrosion-resistant underlayer. In fact, some advanced product lines blend both resin types to balance benefits, delivering tailored performance for consumer electronics, automotive trim, or appliance housings.

Adhesive Performance: Bond Strength and Longevity

Testing—such as lap shear and peel assessments—shows clear trends:

- Free radical adhesives generally excel in tensile and lap shear strength, crucial for stiff assemblies

- Cationic adhesives maintain superior performance under temperature changes and humidity cycling, ideal for exterior and demanding environments

If your production faces repeated thermal or chemical exposure, you’ll want to study options among epoxy adhesives that utilize cationic mechanisms for maximum reliability.

Choosing Photoinitiators for UV Curing

The photoinitiator must match the resin and target UV spectrum:

- For free radical chemistry (e.g., acrylates): typically, benzoin ethers, alpha-hydroxy ketones, or phosphine oxides

- For cationic chemistry (e.g., epoxies): diaryliodonium or triarylsulfonium salts

Getting the match right ensures full-depth cure, reduces tackiness, and maximizes production line yields.

UV Curing Equipment: What Matters?

The speed and quality of cure hinge on:

- Light wavelength and intensity—directly affects curing speed

- Conveyor/batch curing design—improves repeatability for large metal parts

- Cooling and shielding options—to protect heat-sensitive assemblies

Many factories have shifted to LED-based UV systems for energy savings, greater control, and enhanced process stability. UV-LED technology is compatible with both curing chemistries but demands careful matching of photoinitiators.

Common Challenges in UV Curing of Metals

- Shadowed areas may not cure; line-of-sight exposure matters

- Thick sections require dual-cure (UV and thermal/chemical) solutions

- Surface contaminants (oil, oxide layers) can interfere with adhesion

Using appropriate surface preparation techniques—in line with best practices outlined in guides on improving adhesive strength—is crucial for robust, repeatable results.

Industry Examples: Automotive, Electronics, and Beyond

In automotive trim manufacturing, fast UV-curing adhesives minimize fixture time, enabling high-throughput production and durable aesthetic finishes. Electronics manufacturers benefit from the precise application and instant cure to bond sensitive components without heat damage. Appliance makers depend on UV-cured coatings for scratch resistance and vibrant, long-lasting colors.

It’s also common for factories to specify both free radical (for speed and clarity) and cationic (for chemical resistance and flexibility) curing adhesives in different steps of the same assembly process.

Hybrid Systems: Getting the Best of Both Worlds

Modern innovations allow chemists to blend free radical and cationic systems in one formulation—these hybrids cure quickly and offer balanced performance. Hybrid UV adhesives are especially valuable in metal bonding, where complex assemblies require a mix of high strength, fast throughput, and resistance to heat, chemicals, or cyclic load.

Future Trends in UV Curing for Metal Products

Expect rising adoption of dual-cure resins (combining UV with moisture or thermal curing), advanced photoinitiators for lower-energy LED lamps, and surface treatments that improve adhesion to hard-to-bond metals. Sustainability is also in focus, with increased use of low-VOC, low-energy-curing chemistries in all major manufacturing hubs.

Expert Decision Guide: Selecting the Right Curing System

When choosing between free radical and cationic systems for your metal application, consider:

- Required cure speed (free radical for ultra-fast; cationic for flex-cure)

- Surface conditions and sensitivity to oxygen

- Desired coating/adhesive properties (rigidity, flexibility, resistance types)

- Operating temperature and environmental exposures

- Regulatory and sustainability requirements

For custom bonding or sealing tasks, consult specialist UV-curing solutions that address unique process or performance needs, such as selective area protection during metal finishing.

Pitfalls and Process Failures – Lessons from the Line

Skipping proper surface prep, using the wrong photoinitiator, or applying adhesive too thick can lead to poor cure or bond failure. Consistent process controls—such as regular light intensity checks, substrate cleaning, and trial sample testing—help avoid common pitfalls and maintain repeatable, trusted manufacturing results.

Regulatory and Environmental Considerations

UV curing’s energy efficiency and low emissions profile support compliance with modern VOC and worker safety regulations. Cationic systems also often avoid amines and other ingredients that trigger air quality concerns. Factories pursuing green certifications now routinely adopt UV curing technologies as part of sustainability and workplace safety strategies.

Case Study: Bonding Aluminum Connectors in New Energy Systems

For electric vehicle (EV) charging equipment, manufacturers require adhesives that bond aluminum, resist weathering, and maintain conductive connections for years. Cationic-cured UV adhesives have become a standard, matching strict industry standards for reliability. The combination of UV speed, ongoing “dark cure,” and excellent corrosion resistance makes these adhesives well suited for harsh service environments.

Expert Insights from ZDS Adhesive, an Industrial Adhesive Manufacturer

From an application engineering perspective at ZDS Adhesive, consistent bond quality on metals is best achieved when the following rules are followed:

- Match cure system to substrate and environmental requirements

- Control adhesive bondline thickness for reliable fixture and final strength

- Use lap shear and humidity aging tests to verify design standards

- Add plasma or corona treatment for low-energy metals if required

Making the right call reduces rework, downtime, and long-term failures in the field—all critical for competitive manufacturing in 2026 and beyond.

Free Radical vs. Cationic Curing: UV Mechanisms Explained

Both free radical and cationic UV curing mechanisms have revolutionized how metal assemblies are bonded, sealed, or coated. Each approach offers unique strengths—rapid production for free radical systems, robust environmental protection for cationic formulations. By matching the process to your product requirements, you unlock maximum durability, reliability, and efficiency on the assembly line. Forward-thinking facilities blend knowledge, careful design, and proven test methods to choose the right solution for their next-generation metal products.

Frequently Asked Questions

What is the biggest difference between free radical and cationic UV curing?

Free radical systems polymerize acrylate resins quickly after UV exposure but can be inhibited by oxygen, while cationic systems use UV-generated acids to cure epoxy or vinyl ether resins and are not affected by oxygen, providing a more consistent finish.

Which UV curing method is better for outdoor metal products?

Cationic curing adhesives and coatings generally perform better outdoors as they resist humidity, heat cycling, and chemical exposure; free radical systems are best for indoor, high-gloss, or decorative finishes.

Why do some UV-cured adhesives remain tacky?

This is often caused by oxygen inhibition at the surface during free radical curing or incorrect photoinitiator selection. Cationic systems are less likely to have tacky surfaces after UV exposure.

Can UV curing be used on thick or shadowed metal parts?

Standard UV curing is line-of-sight and may not fully process thick or shaded areas. Dual-cure chemistries or multi-step processes (UV plus heat/moisture) are often necessary for complex shapes or deep cavities.

Are there UV adhesive options specifically for aluminum bonding?

Yes, both free radical and cationic UV adhesives are formulated for metals, but cationic-cured epoxies tend to provide superior corrosion resistance and durability for aluminum assemblies.

How do manufacturers ensure reliable bonding to oily or oxidized metal surfaces?

Surface preparation is crucial—cleaning, degreasing, and possibly plasma/corona treatment are used to ensure strong, consistent bonds, regardless of the curing chemistry selected.