Introduction: Demystifying Nano-Coatings for IPX7 Waterproofing of Electronics

As electronics become ever more essential to our daily lives, the demand for durability and reliability is at an all-time high. One standout solution that’s reshaping device protection is nano-coating technology, especially in the context of achieving the rigorous IPX7 waterproofing standard. In this guide, we’ll break down what makes nano-coatings unique, how they’re applied, and why they’re a game changer for manufacturers and consumers alike. From chemistry to assembly-line insights and real product case studies, explore the whole landscape of nano-coatings for IPX7 waterproofing of electronics.

What Is IPX7 Waterproofing in Electronics?

IPX7 describes a water ingress protection level where an electronic device can withstand immersion in water up to 1 meter for 30 minutes. This rating is strictly tested and commonly seen in wearables, audio gear, and smart devices. IPX7 is a threshold indicating not just splash resistance, but real waterproof performance. Traditional sealing can add bulk or restrict heat transfer, so manufacturers seek advanced alternatives. Nano-coatings emerge as an elegant, lightweight way to achieve robust water protection.

The Evolution of Waterproofing: From Gaskets to Nano-Coatings

Previously, waterproofing mainly relied on mechanical gaskets, O-rings, and adhesives, but these can complicate assembly and still fail under stress, vibration, or miniaturization. Nano-coatings herald a shift—applying invisibly thin, chemistry-driven layers directly onto circuits and surfaces, forming hydrophobic “shields” that repel water on contact without altering part fit or heat dissipation. This is transformative for designers obsessed with compactness and multi-functionality.

The Science of Nano-Coating Technology

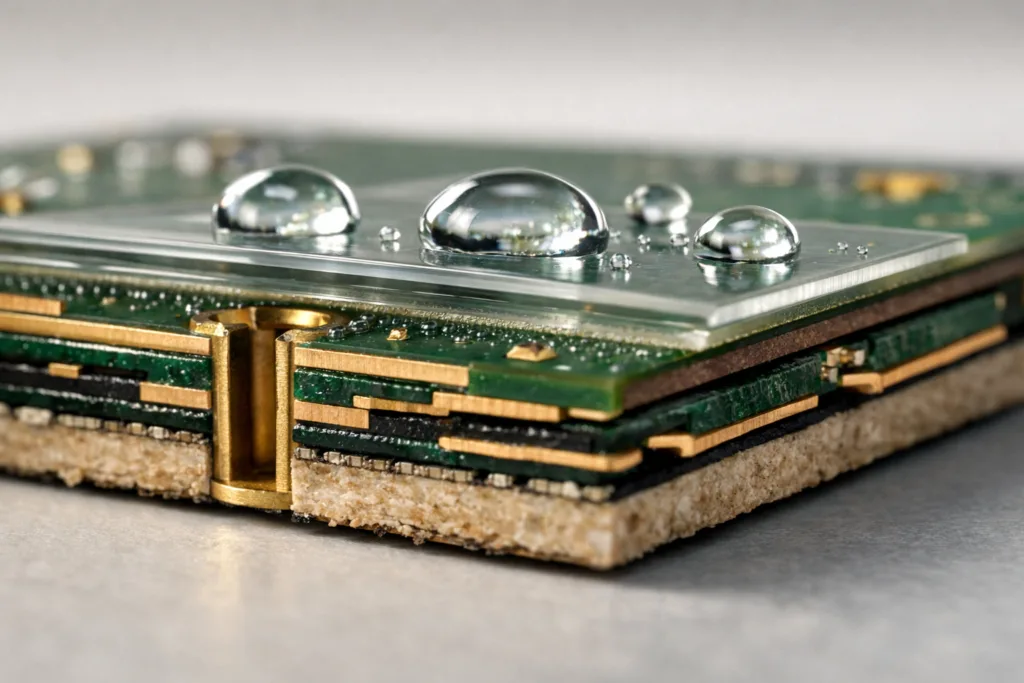

Nano-coatings are ultra-thin films, often less than 100 nanometers thick, engineered at the molecular level. Common chemistries include fluoropolymers, parylene, silicon dioxide (SiO2) derivatives, and even hybrid organic-inorganic systems. These coatings bond at the atomic scale, creating low surface energy barriers that water simply cannot penetrate. The result: fluids bead up and roll off, defying gravity and surface tension, keeping vital electronics dry and functional.

How Nano-Coatings Achieve IPX7 Waterproofing

The secret lies in uniformity and adherence. If a nano-coating forms a seamless, pinhole-free layer over every nook and cranny—connectors, solder joints, and microchips included—it can resist liquid ingress even under moderate pressure. The thinness ensures signals pass unimpeded, essential for RF and sensitive electronics. Manufacturers test waterproofed products with immersion tanks, verifying IPX7 performance through visual inspection, continuity checks, and sometimes even high-voltage isolation probing.

Key Benefits of Nano-Coatings for Electronics Manufacturers

Why are more companies switching to nano-coatings for IPX7 waterproofing? The advantages include:

- Weight and Size Savings: Eliminate mechanical bulk, freeing up design space.

- Process Flexibility: Coating is post-assembly, working with fragile or miniaturized PCBs.

- Thermal Management: Unlike classic potting, doesn’t trap heat within circuits.

- Cost-Effective Scalability: Short cycle times, batch or inline compatibility.

- Improved Yield: Reduces defects linked to human error in gasket application.

For electronics designers, these are powerful levers to deliver robust devices without performance compromise.

Chemistry Behind Modern Nano-Coating Formulations

Most IPX7-focused nano-coatings use perfluorinated compounds or silanes, applied by vapor deposition, plasma-enhancement, or advanced spraying. Hybrid resin systems can be customized for different substrates, including metals, solder masks, and plastics. Epoxy-based coatings are particularly favored for their strong adhesion and durability, but where low dielectric or minimal bulk is critical, parylene or fluoropolymer systems might take precedence.

Process and Application Methods

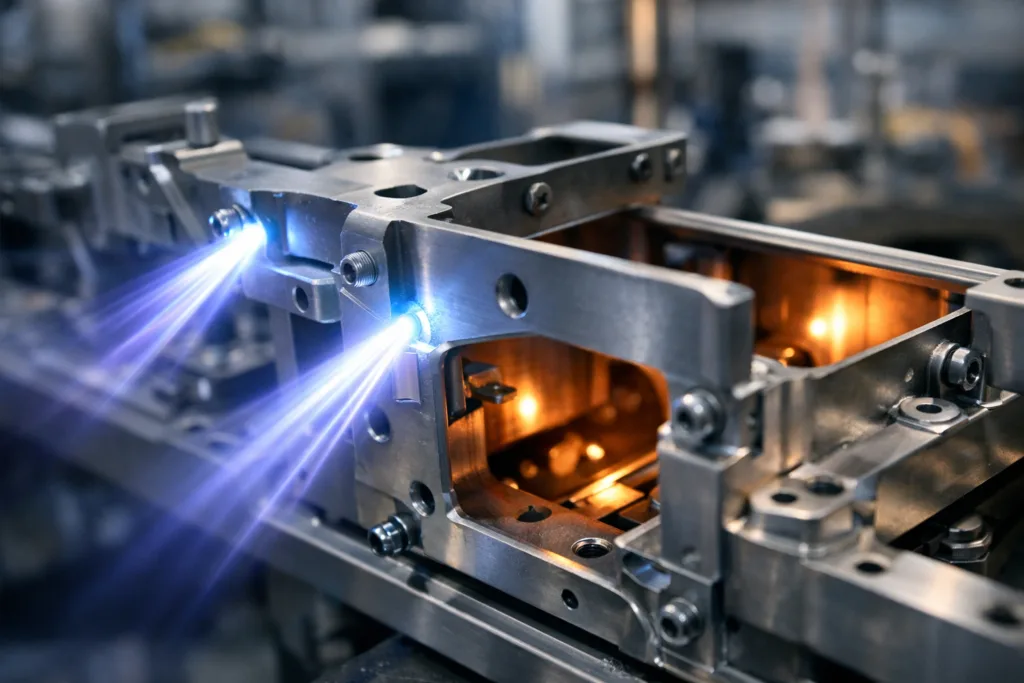

Common nano-coating application processes:

- Spray Coating: Good for large or irregular shapes; efficient for high throughput.

- Dip Coating: Ensures full surface coverage; best for batch jobs or complex assemblies.

- Vapor Deposition: The gold standard for parylene; achieves uniformity even inside tiny gaps.

- Plasma Enhanced Chemical Vapor Deposition (PECVD): Adds cross-linking, boosting chemical resistance and adhesion strength.

For more on application styles, the blog post PCB Coating Showdown: Dip, Brush, or Spray for Reliable Surface Finishing in 2026 details the strengths of each approach. Application decisions depend on the production line configuration, throughput needs, and device complexity.

Nano-Coatings vs. Conformal Coatings: What’s the Difference?

Not all coatings are alike. Standard conformal coatings (like acrylic, polyurethane, or silicone) are thicker—often 5,000 to 100,000 nanometers. They’re better at withstanding mechanical abrasion or corrosive gas environments. Nano-coatings, by contrast, are much thinner and focused on hydrophobicity/oleophobicity; they offer IPX7-level water repellency with less mass, but might not replace conformal coatings in every scenario. The choice depends on environmental risks, device requirements, and process compatibility. See a detailed comparison of PCB protection types here.

Industry Standards for Nano-Coating and IPX7 Certification

Official standards guide both nano-coating performance and waterproofing claims:

- IEC 60529: Definition of IP ratings, including IPX7 water immersion tests

- IPC-CC-830: For conformal, parylene, and hybrid coatings, outlining test and inspection protocols

- UL 94: Flammability ratings (sometimes required for potting/nano products used in batteries)

Manufacturers must integrate both process validation and regular product audits to maintain certification throughout a device’s lifecycle.

Case Studies: Nano-Coatings for Wearables and Audio Devices

Leading brands have successfully rolled out IPX7 devices by leveraging state-of-the-art nano-coatings. For instance, a global smartwatch manufacturer implemented a plasma-applied fluoropolymer coating on both the PCB and internal connectors, passing both immersion and sweat resistance tests. Similarly, premium wireless earbuds now routinely achieve waterproof acoustics using vapor-deposited, pinhole-free nano-films that don’t impact speaker quality or touch sensor function.

Practical Challenges in Nano-Coating Waterproofing of Electronics

No solution is without hurdles. Key challenges engineers face include:

- Uniformity: Achieving consistent coverage, especially on sharp edges or under SMD components

- Reworkability: Many nano-coatings are semi-permanent; repairs can require specialized removal steps

- Material Compatibility: Some chemistries don’t bond well to ultra-low-energy plastics or require priming

- Electrical Testing: Extremely thin films complicate continuity or ICT testing unless mitigated by probing/temporary masks

Common Misconceptions About Nano-Coatings

It’s easy to overestimate or misinterpret nano-coating effects:

- Myth: All nano-coatings guarantee waterproofing—Wrong. Only those properly validated per IEC 60529 can claim IPX7 or higher.

- Myth: Coatings last forever—Incorrect. Wear, UV, or abrasive action can erode films over years of use.

- Myth: Nano-coating makes gaskets obsolete—Reality: For high-pressure or mechanical intrusion, supplemental seals may still be needed.

Balanced product design matches the type of nano-coating with realistic operating conditions.

Latest Innovations: Self-Healing and Multi-Layered Nano-Coatings

Recent research is pushing nano-coatings even further. Self-healing chemistries can close micro-cracks when exposed to water or heat, while multi-layer nano-architectures combine hydrophobic, dielectric, and even antimicrobial functions in a single, seamless package. These advances hint at future IPX8+ rated devices, even for highly complex electronics with moving parts and high throughput assembly needs.

Process Control: Ensuring Consistency in Mass Production

Keeping nano-coating performance stable in high-volume manufacturing is non-trivial. Process engineers rely on in-line thickness gauges, water break tests, and visual or spectroscopic inspection to verify every batch. A single miss can mean catastrophic device failures in the field. This is why rigorous quality management and traceability protocols are essential.

Why ZDS Adhesive Monitors Moisture Pathways in Assembly Lines

From an assembly-line viewpoint at ZDS Adhesive, an industrial adhesive manufacturer, consistent process control for moisture barriers is critical for device reliability. We recommend:

- Pre-cleaning all surfaces (ionic and organic contaminants disrupt bonding)

- Automated thickness verification of nano-coatings post-cure

- Routine humidity cycling and immersion testing to catch rare, random defects

These basic steps, when followed diligently, can increase pass rates and reduce warranty claims.

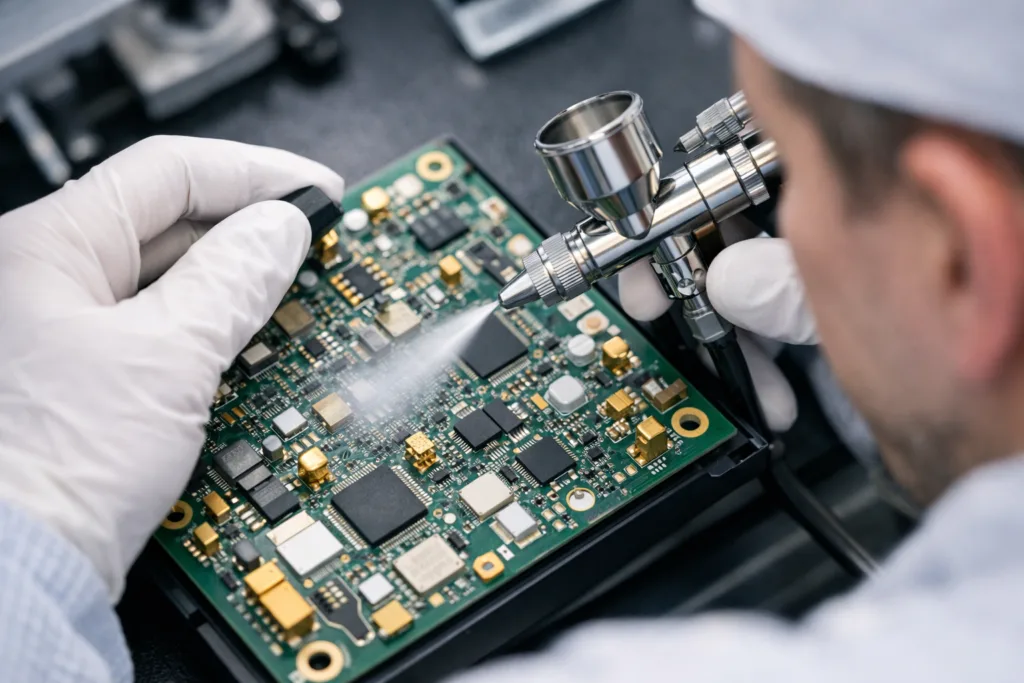

Step-by-Step: The Nano-Coating Application Flow in Practice

Here is a simplified overview of how nano-coating is applied to electronics targeted for IPX7 waterproofing:

- Clean & dry the device (using IPA and controlled air flow)

- Mask areas needing electrical access or shielding

- Apply nano-coating (spray/dip/vapor method, as determined by part shape and line speed)

- Cure or set per chemistry—may involve baking, UV, or simple air dry steps

- Remove masks, perform full function and waterproof test (including immersion and signal checks)

This sequence ensures coverage uniformity and functional integrity.

How to Select the Right Nano-Coating for Your Product

Selection starts by evaluating these factors:

- Device operating temperature, exposure (chlorine, sweat, oil, solvents)

- Permissible coating thickness and effect on mechanical parts

- Adhesion to key substrates (glass, copper, polyamide, plastics)

- Certification requirements (must pass IPX7, UL, etc.)

Consulting with a material scientist or industrial adhesive specialist ensures the correct match of chemistry to your assembly process.

Application Example: Smartwatch PCB with Dual-Layer Nano-Coating

Take a high-end smartwatch with exposed charging pins and an OLED screen. Engineers may use a primary parylene layer (for water/moisture block) topped with a thin fluoropolymer (for oil/fingerprint resistance). This dual system ensures the watch survives both poolside dips and sweaty workouts—meeting IPX7 and cosmetic performance goals in one process.

Nano-Coatings Complement Potting for Mission Critical Applications

Where absolute robustness is required (for example, in automotive or military modules exposed to vapor, vibration, and even harsh chemicals), nano-coating is combined with polyurethane potting compounds to deliver “belt and suspenders” protection: the nano-layer provides fast water repellency on critical circuitry, and potting delivers shock and vibration stability. This dual approach is discussed further in modern manufacturing guides.

Future Outlook: Where Nano-Coating Technology Is Headed

The road ahead is exciting. We expect IPX8+ wearables with proven sweat, chlorine, and seawater resistance. Integration of antimicrobial additives and even energy-harvesting surface chemistries are emerging on device roadmaps. And with more sustainable, lower-VOC formulations under development, nano-coatings are becoming greener while offering ever-better performance in the toughest real-world conditions.

Nano-Coatings for IPX7 Waterproofing of Electronics

Nano-coating technology is no longer reserved for premium devices. It’s quickly becoming the new baseline for mass-market reliability in everything from fitness trackers to industrial sensors. As coverage uniformity, durability, and reworkability continue to improve, IPX7-level waterproof electronics will be as routine as shock- and dust-resistance today. Staying ahead means embracing these innovations, adapting processes, and always aligning materials with end-use environments.

Frequently Asked Questions

What does an IPX7 waterproof rating mean?

An IPX7 rating means an electronic device can withstand immersion in up to 1 meter of water for 30 minutes without damaging performance.

Can nano-coatings completely replace physical gaskets or adhesives?

Nano-coatings offer excellent water and moisture protection, but in high-pressure or complex assemblies, physical seals may still be necessary for full reliability.

How long do nano-coatings last on electronics?

Well-applied nano-coatings can last the device’s lifetime but may degrade if exposed to abrasion, harsh chemicals, or heavy UV over years of use.

Are nano-coatings conductive or do they block signals?

Nano-coatings are electrically insulating but ultra-thin—most do not affect radio frequencies or electrical performance when properly applied.

Can nano-coating be reapplied if damaged?

Yes, but reapplication often requires careful cleaning or stripping of the old layer to ensure new coating adheres without defects.

Are nano-coatings safe for consumer electronics?

Yes, nano-coatings used in electronics manufacturing undergo strict safety and environmental testing to ensure no harm to users or devices.

Related Reading

- 7 Steps to Eliminate ‘Orange Peel’ Defects in Conformal Coating

- How Water Absorption Undermines Epoxy Electrical Protection

- Dual-Cure Systems: Solving Shadow Area Failures in UV Curing

- Boosting Smart Ring Reliability with Micro-Potting Techniques

- 12 Crucial Benefits of UV Curing Adhesives for Electronics