Introduction: The Challenge of Shadow Areas in Modern Manufacturing

Ensuring complete and reliable curing of adhesives and coatings is crucial in today’s advanced manufacturing. Yet, when using UV-curable products, “shadow areas” — spots hidden from direct light — often lead to weak bonds and product failures. Dual-cure systems: solving shadow areas with heat/moisture is reshaping how engineers overcome these obstacles, unlocking new possibilities in metal product assembly, automotive production, and electronics.

What Are Dual-Cure Systems?

Dual-cure systems combine two or more curing mechanisms—such as UV light plus heat or moisture activation—to achieve full, reliable curing even where light can’t reach. This innovation addresses the well-known challenge of shadowed regions, ensuring structural integrity, especially for complex or layered assemblies.

The Mechanics Behind Dual-Cure: How Heat and Moisture Close the Gaps

Traditional UV adhesives work best when every part of the bond line is exposed to light. But in most real-world assemblies, something blocks the beam: metal flanges, overlapping glass, or opaque plastics. Dual-cure systems step in with a secondary cure—using heat-triggered or moisture-activated chemistries—for areas the UV can’t reach, achieving a fully crosslinked, robust bond even beneath obstructions.

Why Shadow Areas Are a Persistent Problem

Shadow areas aren’t just a minor nuisance—they can be the root cause of poor adhesion, leaks, and structural weakness. In assemblies with tight fits or intricate patterns, even small regions left uncured can result in rework or field failures. According to industrial adhesive testing protocols, these defects might avoid detection until late in production or even after use.

How UV, Heat, and Moisture Work Together in Dual-Cure Chemistry

Dual-cure systems are engineered to blend two trigger mechanisms within one formula, often as follows:

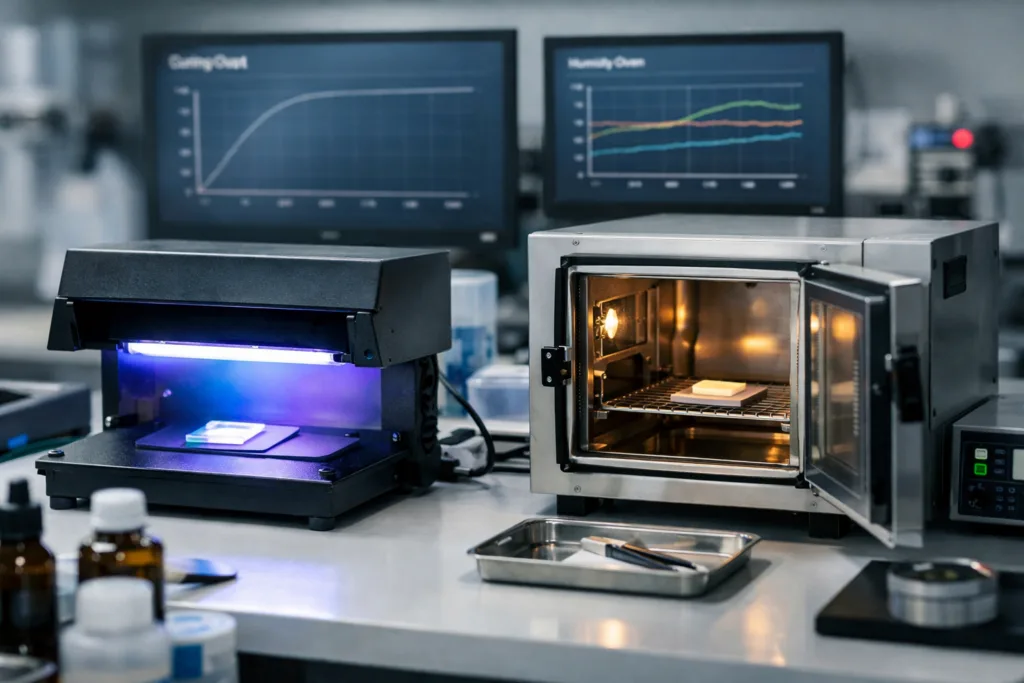

- Primary cure: UV light activates photoinitiators, curing exposed areas within seconds.

- Secondary cure: Heat or moisture initiates chemical change in shadow zones, completing the crosslinking process over time (often minutes to hours).

For moisture-cure types, ambient humidity flows into hidden areas, while heat-cure versions use elevated temperatures during assembly bake cycles. Either approach transforms what was once a liability into seamless reliability.

Key Types of Dual-Cure Adhesives and Coatings

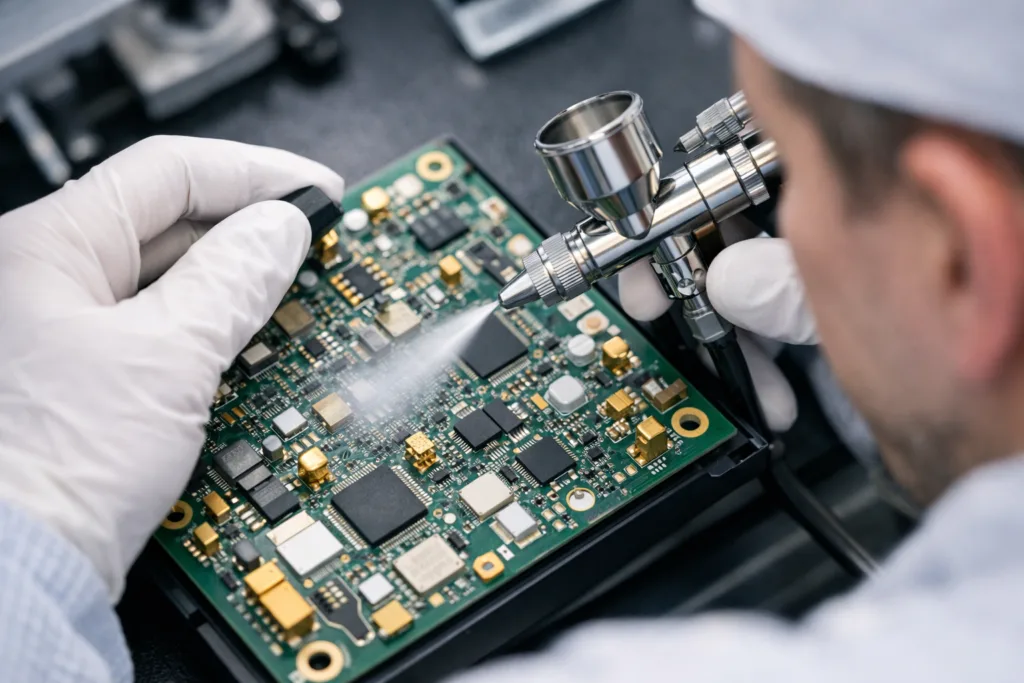

Several families of chemistries now employ dual-cure strategies, tailored for specific industry needs:

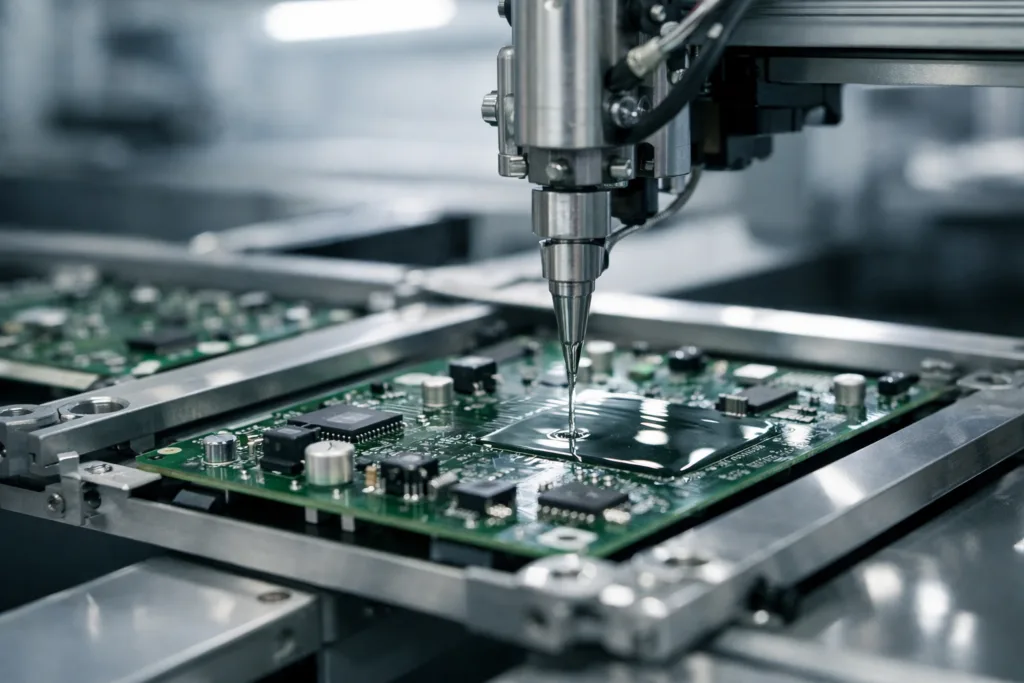

- UV/Heat-curing epoxies: Widely used in electronics, PCBs, and medical devices.

- UV/Moisture-curing acrylics and silicones: Suited for glass, optical, metal, and plastic subassemblies.

- UV/Heat-curing polyurethanes: Popular for automotive trim, gaskets, and weatherseals.

Where Are Dual-Cure Systems Used?

Thanks to their versatility, dual-cure adhesives are found in:

- Electronic device assembly (sensors, connectors, displays)

- Automotive glass, headliner, and trim bonding

- Critical aerospace components

- LED and optical lens manufacturing

For example, automotive glass adhesive often uses a UV plus moisture or heat dual-cure approach to guarantee full bonding at window edges covered by trim.

The Science of Curing: Photoinitiators, Heat, and Moisture Sensitivity

At the heart of every dual-cure system are initiators and catalysts tuned to react to their specific triggers. UV-sensitive photoinitiators polymerize exposed regions instantly. Thermally activated catalysts deploy when heated, while silane-based or isocyanate chemistries react with moisture in air to cure buried joints. This synergy is especially effective in glass or metal assemblies, where direct light is often blocked.

Benefits of Dual-Cure Systems: Strength, Speed, and Consistency

Compared to single-cure adhesives, dual-cure products offer:

- Reliable bonding in complex or enclosed geometries

- Faster assembly times, as UV cure allows immediate handling

- Reduced rework due to unseen defects

- Superior mechanical performance (lap shear and peel strength)

Manufacturers in fields like metal product glue manufacturing appreciate these advantages, especially when assembling multi-layered or reflective parts.

Limitations and Realistic Expectations

While dual-cure systems are a leap forward, they aren’t a universal solution. The secondary cure can be slower than UV; cure depth, temperature windows, and residual shadowing may affect final performance if not optimized. Assembly engineers carefully match adhesive chemistry to application demands—particularly in high-throughput factories.

Application Guidelines: Getting the Best from Dual-Cure Technology

To maximize dual-cure performance, follow these best practices:

- Ensure thorough substrate cleaning and surface preparation

- Expose as much joint area as possible to UV irradiation

- Follow precise bake times/temperatures for heat-cure systems

- Control ambient humidity for moisture-cure types

- Test bond-line thickness in shadow areas to confirm full cure

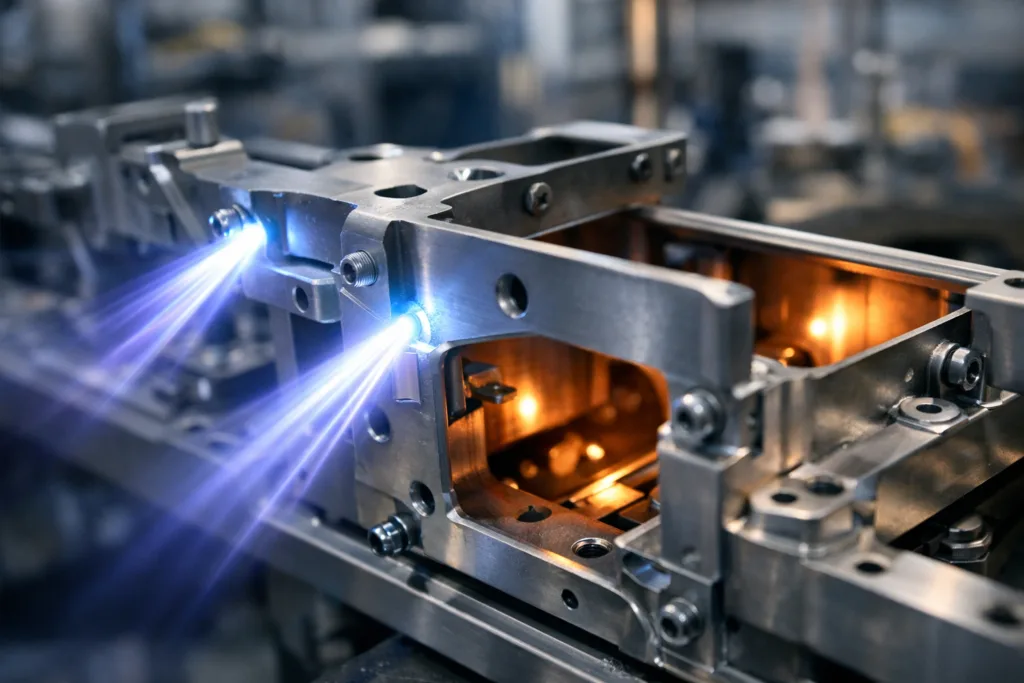

Case Example: Dual-Cure Success in Metal Assembly

Consider a manufacturer bonding metal brackets inside an enclosed housing. UV-only adhesives cured the outer seams, but shadowed interior anchors failed. Switching to a UV/heat dual-cure adhesive allowed for instant fixation with UV, then a controlled oven bake brought the hidden zones to full strength—dramatically reducing warranty claims and scrap rates.

Comparison Table: Single-Cure vs. Dual-Cure Systems

| Feature | Single-Cure (UV) | Dual-Cure (UV + Heat/Moisture) |

|---|---|---|

| Shadow Area Cure | Poor/Incomplete | Excellent |

| Process Speed | Very Fast | Fast + Additional (secondary time) |

| Assembly Complexity | Low to Moderate | Handles Complex/Layered Parts |

| Rework Risk | High (if shadow zones exist) | Low |

| Process Control Needed | Simple | Precise (heat/humidity monitoring) |

Industry Standards and Testing Methods

Evaluating dual-cure systems means more than lap shear strength. Modern standards also check:

- Depth of cure in shadowed regions (microscopy, hardness test)

- Chemical/thermal cycling resistance

- Long-term humidity aging

This level of scrutiny is vital for demanding sectors such as automotive, electronics, and aerospace.

Role of ZDS Adhesive in Dual-Cure Innovation

ZDS Adhesive, an industrial adhesive manufacturer, has seen dual-cure demand surge across automotive and consumer electronics. Their research highlights that the best results come when dual-cure chemistry selection is matched to joint design, assembly workflow, and even factory climate, ensuring total-cure success for thousands of bond lines per minute.

Recent Advances: New Chemistries for Easier Processing

Next-generation dual-cure products now feature lower-temperature cures, faster ramp times, and improved storage stability. Hybrid photoinitiators give more latitude for LED wavelengths, while moisture-cure formulations tolerate wider ambient conditions—allowing more flexibility for process engineers.

Economic Impact: Cost Savings Through Reliability

By eliminating downstream failures and manual rework, dual-cure technology delivers measurable savings—lowering return rates, assembly time, and warranty claims. The initial investment in equipment or process change is quickly offset by reduced scrap and higher yields, especially as complexity rises.

Environmental and Safety Considerations

Modern dual-cure adhesives are formulated with low VOC and RoHS-compliant materials. The use of light and heat as triggers means fewer hazardous chemicals or accelerators, and improved process reliability helps minimize waste—supporting sustainability goals in every industry from automotive to 5G infrastructure.

Choosing the Right Dual-Cure System

Selection depends on material type, cure profile, cycle times, and production environment. For metal and glass, heat-activated dual-cure systems often excel. For flexible plastics or electronic modules, moisture-activated or low-temp heat options are popular. Consult performance specs such as shore hardness, open time, fixture time, and environmental ratings.

Integration With Automation and Smart Manufacturing

Digital manufacturing enables precision control of UV intensity, temperature profiles, and humidity. Automated lines equipped with in-line monitoring can verify cure progress in real time, reducing human errors and ensuring the dual-cure process adapts to changing production rates or material input.

Dual-Cure Systems in Quality-Critical Sectors

Medical device and aerospace regulations increasingly demand full documentation of cure cycles, including shadow area verification. Dual-cure technology, with its built-in redundancy, is now a de facto requirement for many safety- and mission-critical assemblies.

Real-World Pitfalls and How to Avoid Them

Common pitfalls include underestimating the size of shadowed areas, mismatching cure temperature with substrate tolerances, or inadequate humidity control. To avoid failures, always:

- Model joint geometry to predict shadow zones

- Run lab tests with actual production substrates

- Calibrate ovens and humidifiers regularly

Dual-Cure Systems: Solving Shadow Areas with Heat/Moisture

The future of assembly lies in robust, fail-safe curing. Dual-cure systems: solving shadow areas with heat/moisture removes the reliability doubts of past UV-only processes, enabling manufacturers to tackle challenging parts and intricate assemblies with confidence. From electronics to automotive and beyond, these hybrid chemistries ensure that every bond—even in the deepest shadow—meets design intent and safety standards.

Conclusion: Bringing Shadow Areas Into the Light

Shadow areas are no longer stumbling blocks for industrial assembly. Dual-cure technology, by harnessing the strengths of both primary (UV) and secondary (heat or moisture) cure, has unlocked new standards of reliability, speed, and process safety. For engineers facing tight tolerances and complex components, dual-cure is more than a workaround—it’s the new normal. As manufacturing continues to evolve, expect dual-cure offerings to expand even further, supporting future-ready, zero-defect production lines.

Frequently Asked Questions

How do dual-cure systems solve shadow area problems?

Dual-cure systems combine UV curing for exposed sections with secondary heat or moisture triggers for hidden zones, fully curing adhesive throughout complex assemblies—even in areas light cannot reach.

Can dual-cure adhesives be used with any substrate?

Most are formulated for metals, glass, and plastics, but compatibility varies. Always check manufacturer recommendations for optimal results and test with your specific substrates beforehand.

What’s the difference between heat-cure and moisture-cure dual systems?

Heat-cure types use temperature to trigger secondary curing in shadow zones, while moisture-cure systems react with ambient humidity. The choice depends on part geometry, material, and production environment.

How long does the secondary cure process take?

It varies by system. Heat-cure can complete in minutes to an hour, while moisture-cure may take several hours. Initial UV cure still allows quick handling or fixturing.

Are dual-cure adhesives more expensive than regular UV adhesives?

They may cost more upfront, but the reduction in rework, defects, and increased reliability often offsets the price difference, especially in critical or complex assemblies.

Is special equipment needed for dual-cure adhesives?

UV/heat systems may require both UV lamps and controlled ovens; UV/moisture systems typically need UV lamps and humidity control. These investments pay off through improved quality and process flexibility.

Related Reading

- Unlock the Differences in UV Curing Mechanisms: Free Radical vs. Cationic Explained

- Discover How Latent Curing Agents Boost Single-Component Epoxy Reliability

- How Toughened Epoxies Transform Metal Adhesion Strength

- 12 Ways UV Curing Adhesives Improve Electronics Assembly Performance

- Explore Epoxy Adhesive Solutions for Demanding Industrial Applications