Introduction: LED UV (365nm/395nm) vs. Mercury Lamps: A Comparison

For manufacturers, engineers, and process specialists, choosing the right UV curing lamp—whether LED UV (365nm/395nm) or traditional mercury lamps—impacts productivity, quality, safety, and costs. As UV curing technology evolves, it’s vital to understand the nuanced strengths and trade-offs of each option. This comparison examines LED UV and mercury lamps across wavelength, energy efficiency, operational costs, environmental impact, curing performance, and real-world applications in 2026. Whether you’re upgrading production lines, developing adhesives for new materials, or weighing eco-compliance, this article delivers practical insights for informed decision-making.

Understanding UV Curing: Basics and Beyond

UV curing is a process that uses ultraviolet light to quickly harden adhesives, coatings, and inks on a range of surfaces. This method offers speed, precision, and reliability—delivering robust bonds and seamless finishes in industries from electronics to automotive. Both LED UV and mercury lamps serve as sources of UV energy, each with unique operating wavelengths and system requirements.

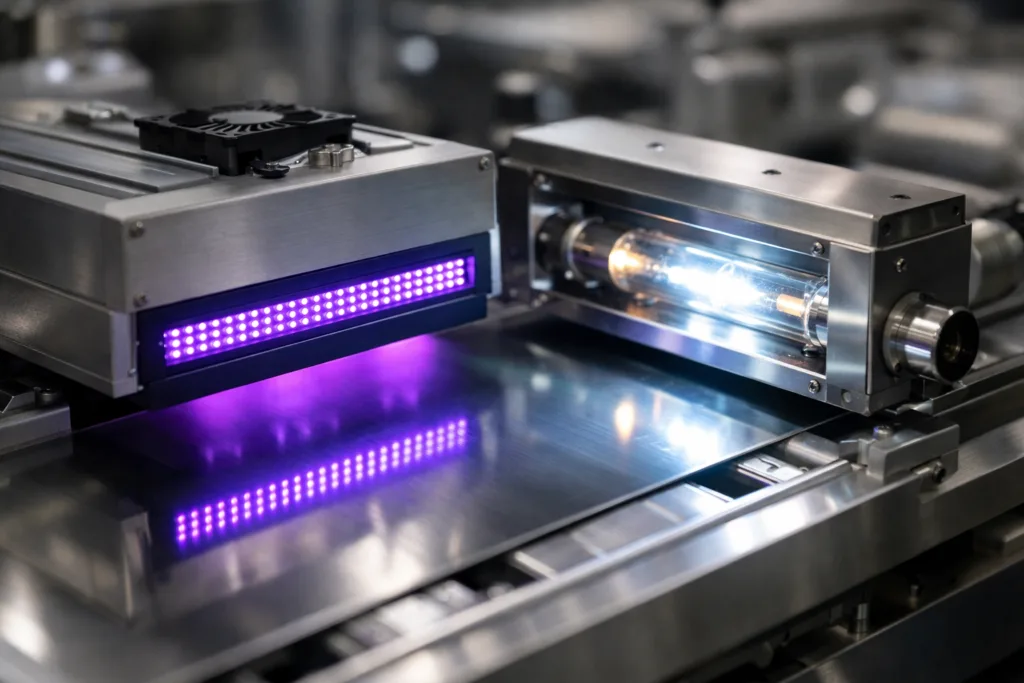

What Are LED UV (365nm/395nm) Curing Lamps?

LED UV curing lamps emit focused ultraviolet radiation at specific wavelengths, most commonly 365nm (closer to traditional mercury) and 395nm (well-suited for newer photo-initiator chemistries). LEDs convert electrical energy directly into UV light, offering instant on/off control and high consistency. They are increasingly common in industrial adhesive applications, especially where process stability and energy efficiency matter.

Understanding Traditional Mercury UV Lamps

Mercury lamps, sometimes called arc lamps, generate broad-spectrum UV by initiating an arc through vaporized mercury inside a quartz envelope. With strong emissions around 365nm (and additional peaks at 254nm, 405nm, etc.), they’ve been the industry standard for decades, widely used in curing and surface finishing.

Key Differences: LED UV (365nm/395nm) vs. Mercury Lamps

The table below summarizes the major distinctions between these two UV curing technologies:

| Feature | LED UV (365nm/395nm) | Mercury Lamps |

|---|---|---|

| Emission Wavelength | Narrow (typically 365nm or 395nm) | Broad (multiple peaks, incl. 365nm) |

| Startup Time | Instant | Few minutes (warm-up required) |

| Energy Efficiency | High (focused output) | Lower (lots of heat produced) |

| Operational Costs | Lower (longer life, less upkeep) | Higher (lamp changes, cooling, shielding) |

| Heat Emission | Minimal | Considerable |

| Environmental Impact | No toxic mercury | Mercury is hazardous |

| Curing Speed/Depth | Dependent on chemistry, excellent with matched adhesives | Excellent with wide photoinitiator range |

Wavelengths Explained: 365nm vs. 395nm

Wavelength selection affects curing depth, speed, and compatibility with adhesives. 365nm closely matches traditional mercury lamp output, ensuring reliable curing with older photoinitiators. 395nm, slightly longer, is tailored for advanced, efficient photoinitiators that excel with LED energy while emitting less heat. When updating existing lines or evaluating new adhesives, always check manufacturer recommendations for optimal wavelength. For in-depth analysis on adhesive performance at different wavelengths, see 12 Must-Know Benefits of UV Curing Adhesives for Electronics Assembly.

Energy Efficiency and Operational Costs Compared

LED UV systems are widely praised for energy efficiency. They emit targeted wavelengths with minimal wasted energy, translating into lower power bills and reduced HVAC load. Longer operational lifetimes mean fewer lamp replacements—a major time and cost saver. In contrast, mercury lamps convert a large portion of energy into heat instead of usable UV, increasing both energy use and air conditioning demands. Downtime for lamp warm-up, cooling, and scheduled replacement also adds hidden costs.

Maintenance and Lifespan: What to Expect

On average, LED UV lamps last 10,000–20,000 hours—far outpacing the 1,000–2,000 hours typical for mercury lamps. Fewer maintenance shutdowns, fewer part replacements, and reduced technician hours make LEDs increasingly attractive for high-volume, just-in-time manufacturing.

Environmental Impact: The Mercury-Free Advantage

The move to LED UV curing reduces hazardous waste. Mercury lamps, once spent, require careful disposal due to their toxic content. Accidental breakage introduces workplace and environmental hazards. LED UV systems contain no mercury, align better with RoHS/REACH goals, and help facilities aiming for sustainable manufacturing certifications. For industries prioritizing green chemistry, this distinction is often non-negotiable.

Curing Performance: Depth, Speed, and Consistency

Mercury lamps excel at curing adhesives, inks, and coatings that demand a broad UV spectrum. Their high peak intensity drives deep and rapid cures across a wide range of materials. By comparison, LED UV’s narrow peak can limit curing with traditional chemistries but is highly consistent and effective with modern, well-matched photo-initiators—including those found in industrial adhesives engineered expressly for LED systems. Proper pairing of adhesive, lamp, and process unlocks rapid, repeatable cures with minimal process variability.

Heat Management: Process Stability and Sensitive Substrates

LED UV lamps run cool, emitting a fraction of the radiant and convective heat of mercury systems. This opens new application windows for heat-sensitive plastics, electronics, and composite assemblies, reducing risk of warping or thermal stress. Mercury lamps, conversely, can limit part selection and sometimes require chilling systems or heat shields—adding system complexity. Learn how temperature control impacts adhesive processes in Thermal Management Mastery: 13 Proven Methods for Controlling Exothermic Reaction in Large Epoxy Castings.

Material Compatibility: What Can You Cure?

Mercury lamps support a broader photochemical range, curing everything from deep-layer epoxies to thick pigmented inks, thanks to their multi-peak emission. LED UV, when adhesives are formulated for 365nm or 395nm, delivers crisp cures for clear, thin coatings and transparent substrates. As adhesive formulation evolves, most major resin types (acrylic, epoxy, silicone, polyurethane) now have LED-optimized versions for most production needs.

Footprint and Integration: Upgrading Existing Lines

LED UV lamp modules are compact, lightweight, and easily integrated into modern automated lines. Their low heat output simplifies mounting and enclosure requirements, an advantage when floor space is at a premium. Mercury UV systems are bulkier due to shielding, cooling fans, and lamp ballasts. Upgrading to LED UV may demand photoinitiator reformulations but enables leaner, more flexible cell designs.

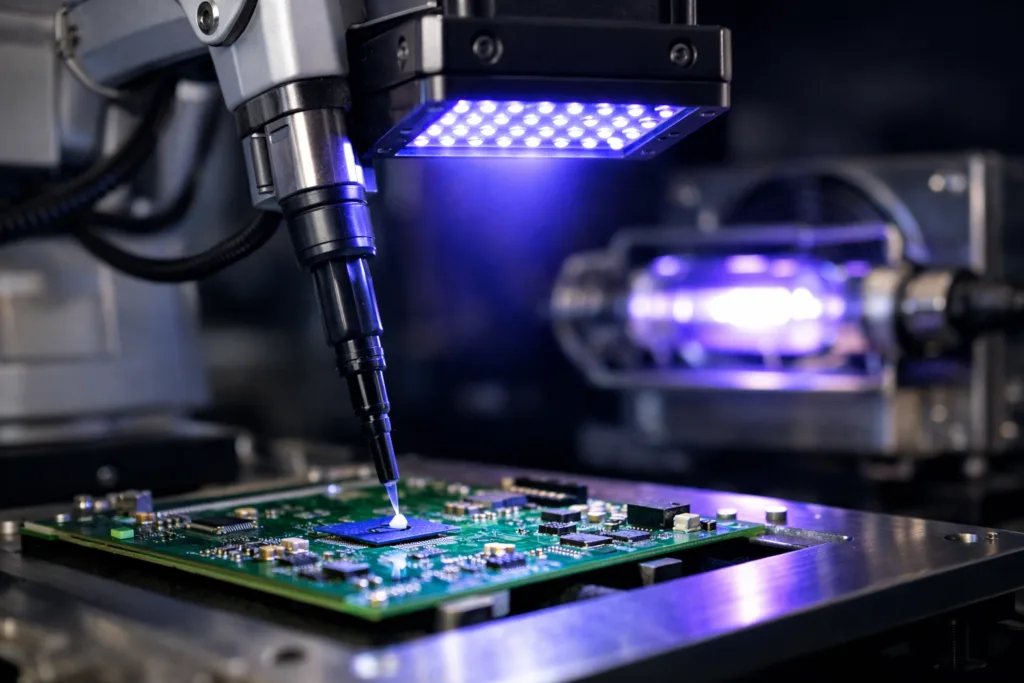

Case Study: Transitioning to LED UV in Electronics Assembly

In 2025, a mid-sized electronics manufacturer switched from mercury arc lamps to 395nm LED UV lamps for circuit board conformal coating. Their goals were shorter cycle times, lower heat, and reduced energy bills. The result: a 40% reduction in energy use, 75% cut in lamp maintenance, and improved first-pass yield, thanks to uniform cure and no lamp downtime. By working closely with their UV-curable maskant supplier, they eliminated shadow cure problems—all while meeting stricter workplace safety targets.

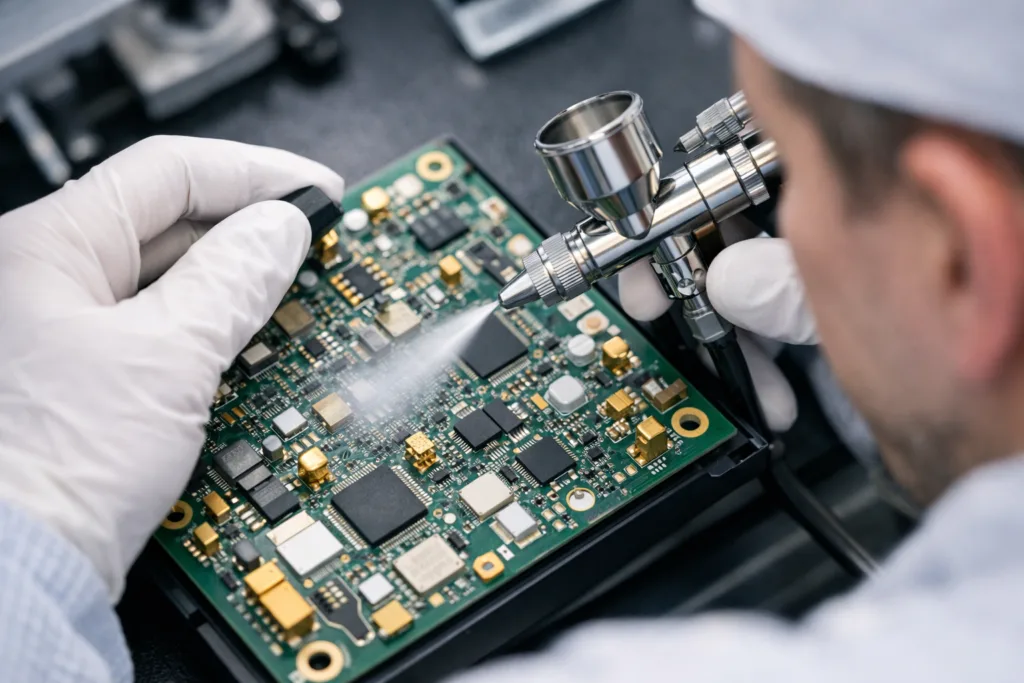

Health and Safety Considerations for Each Lamp Type

Mercury lamps require careful handling, shielding, and ventilation to protect workers from both UV exposure and accidental mercury release. Shattered bulbs are a hazardous-material incident on any line. LED UV systems significantly lower these risks—not only due to their mercury-free design, but also because their instant on/off control reduces accidental exposures during maintenance and cleaning.

Ease of Use: Controls, Monitoring, and Process Feedback

LED UV systems offer precise electronic control, from intensity modulation to strobing. This allows real-time process tuning for variable substrates and fast changeovers. Mercury systems, on the other hand, are more dependent on fixed-output ballasts and analog feedback, making them less flexible in modern digital manufacturing environments.

Economics: Upfront Cost Versus Long-Term ROI

LED UV systems have a higher upfront price tag versus mercury systems. However, over the full operating lifetime—factoring in energy use, maintenance, downtime, and safety/environmental compliance—LED systems routinely deliver lower total cost of ownership. For lines running multi-shift, the savings compound over time.

Regulatory Landscape: Compliance Trends (RoHS/REACH/Local)

Global shifts toward environmental responsibility have led regulators to crack down on mercury use and disposal. From 2025, many industries face stricter limits or outright bans on new mercury lamp installations. LED UV systems help future-proof operations, keeping compliance simple and costs predictable.

Advanced Applications: When Mercury Still Has an Edge

Despite their drawbacks, mercury lamps remain ideal for certain applications requiring deep-layer or highly pigmented cures (like thick black coatings or dense printed inks), especially with legacy lines or unique chemistries. The broad spectral output activates a wide variety of photoinitiators, which may not yet be optimized for LED.

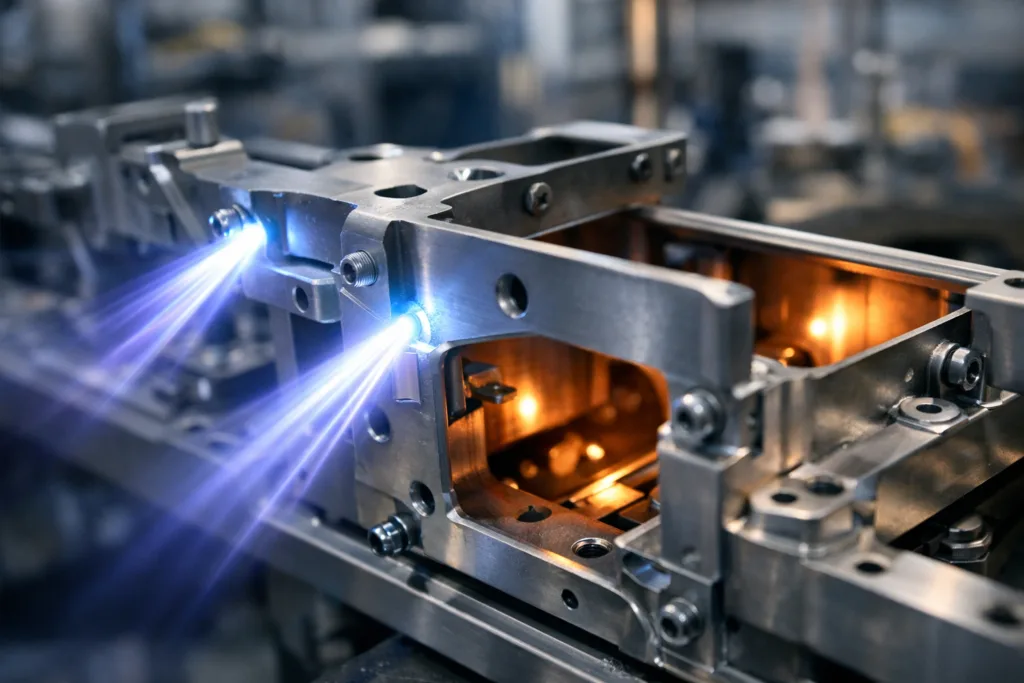

Emerging Trends: The Future of UV Curing Technology

LED UV lamp technology continues to improve in power density, cost-efficiency, and spectral tuning. Hybrid curing systems—combining LED UV with supplementary narrow-band lamps—address demanding or mixed-material applications. With new photoinitiator packages and smarter process controls, expect to see LED adoption accelerate, with mercury phased out except for niche needs.

LED UV (365nm/395nm) vs. Mercury Lamps: A Comparison

Summing up, LED UV (365nm/395nm) and mercury lamps each have their place in today’s manufacturing environment. LEDs excel in energy savings, low maintenance, and safe, sustainable operations—particularly for new lines, green initiatives, or heat-sensitive substrates. Mercury lamps, while dated, can still outperform for legacy chemistries and deep or pigmented cures. The choice ultimately hinges on the chemistry in use, process throughput, regulatory requirements, and long-term operating goals. Carefully review all adhesive and substrate requirements, and consult with engineering teams to maximize line efficiency and future-readiness.

Conclusion and Industry Takeaways

The ongoing shift toward LED UV curing technology isn’t just a trend—it’s a practical leap in sustainability, safety, and operational stability. Manufacturers who embrace LED UV (365nm/395nm) achieve measurable energy reductions, improved uptime, and easier compliance with environmental standards. That said, mercury lamps remain a valid solution for certain legacy and specialty applications. Regularly reviewing your curing and adhesive processes ensures you’re harnessing the best outcomes—for your business, workforce, and the planet.

Frequently Asked Questions

Are LED UV lamps always better than mercury lamps?

Not always. LED UV lamps are generally superior in energy efficiency, lifespan, and safety, but mercury lamps can outperform them for very thick or highly pigmented materials needing broader UV spectra.

Can I simply replace mercury lamps with LED UV on my current line?

Direct replacement is often not possible. Many adhesives and coatings require adjustment for optimal curing at LED wavelengths. Always confirm compatibility with your material suppliers.

What’s the ideal wavelength for curing adhesives: 365nm or 395nm?

It depends on the photo-initiator chemistry of your adhesive. 365nm is closer to mercury output and best for older formulations, while 395nm works well for modern, LED-optimized chemistries.

How do operational costs compare between LED UV and mercury lamps?

LED UV systems have higher upfront costs but save money over time through lower energy use, longer lamp life, and reduced maintenance and disposal costs.

What are the environmental risks associated with mercury lamps?

Mercury lamps pose significant risks due to their toxic mercury content, requiring careful disposal and handling to prevent environmental contamination and workplace exposure.

What industries benefit most from switching to LED UV curing?

Electronics, automotive, medical devices, and printing industries especially value LED UV curing for its speed, low heat, and eco-friendly profile. New lines and retrofits see the biggest gains.