When businesses seek custom adhesive solutions, they often encounter two manufacturing models: OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer). Understanding the difference is critical for product development, brand strategy, and market positioning.

ZDS™ is a trusted adhesive manufacturer providing innovative bonding solutions under both OEM and ODM frameworks. With years of experience in custom adhesive production, ZDS™ partners with businesses to bring their bonding ideas to life—whether they need unique formulations or ready-to-brand solutions.

Understanding the Basics: OEM vs. ODM

What is OEM in Adhesive Manufacturing?

OEM adhesive manufacturing involves creating products based on the buyer’s specific designs, formulas, or requirements. The client provides:

- Proprietary formulations or design specifications

- Detailed performance standards

- Packaging guidelines (if needed)

The OEM manufacturer’s role is to produce the adhesive exactly to those specifications without altering the formulation.

Ideal for: Companies with in-house R&D capabilities or patented adhesive technologies.

What is ODM in Adhesive Manufacturing?

ODM adhesive manufacturing allows businesses to leverage the manufacturer’s existing formulations and designs, with optional customization. Clients often brand the finished product under their own labels.

This model is more flexible for businesses that want:

- Faster time-to-market

- Lower development costs

- Minimal technical input in formulation

Ideal for: Startups or brands seeking private-label adhesives with minimal R&D investment.

Key Differences Between OEM and ODM Adhesive Manufacturing

| Aspect | OEM Adhesive Manufacturing | ODM Adhesive Manufacturing |

|---|---|---|

| Product Ownership | Client owns design/formulation | Manufacturer owns base formulation |

| Customization Level | High – fully customized | Moderate – based on existing designs |

| R&D Requirements | Required from client | Provided by manufacturer |

| Time to Market | Longer (due to custom development) | Shorter (ready-made solutions) |

| Cost Structure | Higher upfront investment | Lower development costs |

Choosing Between OEM and ODM for Adhesives

When to Choose OEM

- You require exclusive adhesives not available elsewhere

- You have internal expertise in chemical formulation

- You want full control over performance and IP

When to Choose ODM

- You need a proven adhesive formula quickly

- You are launching a new private-label brand

- You want to reduce R&D and testing timelines

Industry Use Cases

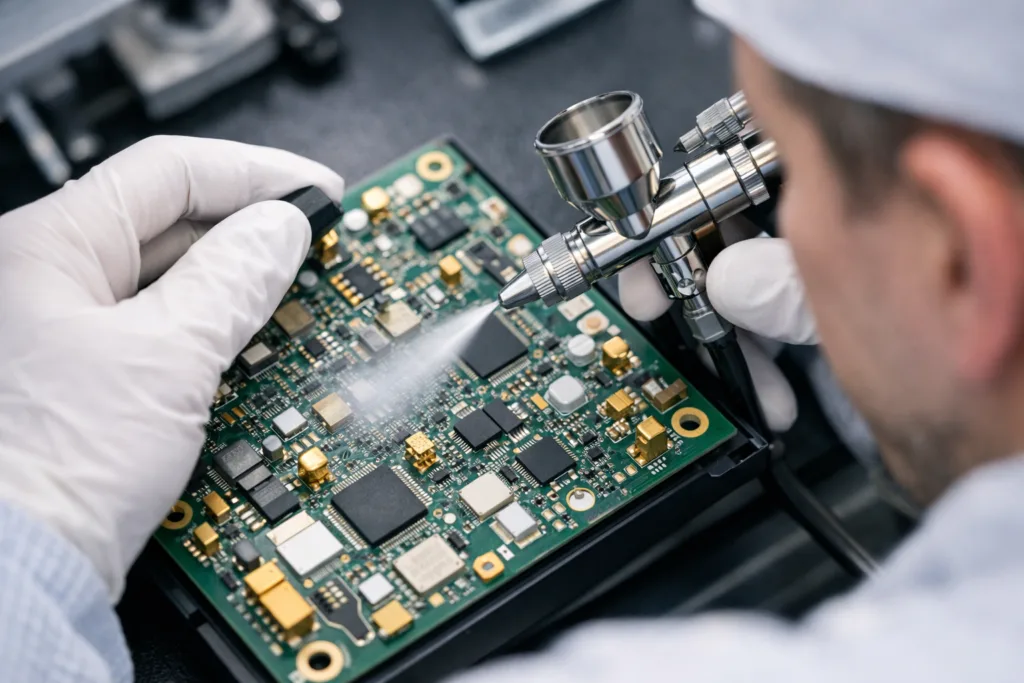

OEM Use Case: Aerospace Adhesives

A client in the aerospace industry worked with ZDS™ to develop an adhesive resistant to high altitude and temperature variations. The adhesive needed to meet rigorous aerospace standards and was entirely formulated in-house and produced under OEM terms.

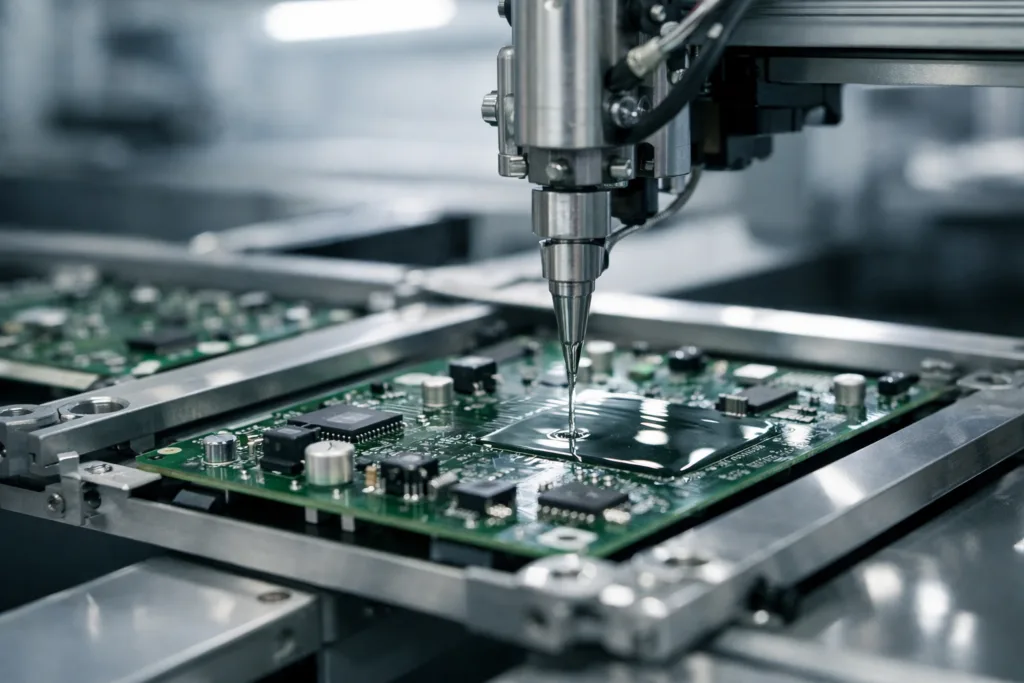

ODM Use Case: Consumer Electronics

A startup needed a reliable pressure-sensitive adhesive for smartphone parts. ZDS™ offered a high-performance ODM formulation, which the client rebranded under their own label, avoiding lengthy R&D processes.

Benefits of Working with a Dual OEM-ODM Partner

Manufacturers like ZDS™ who offer both models provide flexibility as your business evolves. You can start with an ODM product to test the market and later scale into OEM for more tailored solutions.

Advantages include:

- Scalable production capabilities

- In-house R&D for future OEM projects

- Faster prototyping and testing

- Regulatory compliance support

Frequently Asked Questions (FAQs)

1. Can I start with an ODM adhesive and later move to an OEM model?

Yes. Many companies begin with ODM to test demand and later switch to OEM when scaling or differentiating their product line.

2. Are OEM adhesives always more expensive?

Not necessarily. While development costs are higher, OEM adhesives may yield better ROI through performance optimization and brand exclusivity.

3. Is my brand protected in ODM manufacturing?

Yes. Manufacturers like ZDS™ offer private labeling options, ensuring your brand identity is maintained even when using standardized formulations.

Final Thoughts: Which Model Is Right for You?

Your choice between OEM and ODM adhesive manufacturing depends on your business goals, budget, and technical capabilities. If speed and simplicity are your priorities, ODM is a smart path. If control, innovation, and IP ownership matter most, OEM may be the better fit.

Partnering with ZDS™ ensures that whichever model you choose, you’re backed by an industry leader in adhesive innovation and manufacturing excellence.