Introduction: Why Replacing Welding with Structural Adhesives in Aluminum Car Bodies Is Reshaping Automotive Manufacturing

Structural adhesives are rapidly transforming how aluminum car bodies are assembled. Compared to traditional welding, adhesives offer flexibility, lighter joints, and improved durability. Manufacturers worldwide are exploring alternatives to welding, seeking safer, more efficient ways to join lightweight metals. In this article, we’ll examine the impressive advantages and crucial challenges of replacing welding with structural adhesives in aluminum car bodies, provide practical examples from global carmakers, and offer expert insights into what this shift means for the automotive industry in 2026 and beyond.

Understanding Aluminum Car Body Construction

Aluminum is increasingly used for car bodies thanks to its high strength-to-weight ratio and corrosion resistance. However, aluminum’s thermal and mechanical properties make it difficult for traditional welding methods. Adhesive bonding offers solutions to these technical constraints.

The Composition and Benefits of Aluminum in Autos

Automakers choose aluminum to reduce vehicle weight, boost fuel efficiency, and enhance crash performance. Its unique composition and surface characteristics present specific joining challenges.

Traditional Welding Methods for Aluminum Car Bodies

Aluminum welding involves MIG, TIG, or resistance spot techniques. These methods require precise control and special treatments, often leading to heat distortion and weakened metallurgical properties.

What Are Structural Adhesives?

Structural adhesives are specially formulated polymers designed to create deep, permanent bonds between substrates under high load and stress. Common types include epoxy, polyurethane, acrylic, and cyanoacrylate.

Types of Structural Adhesives Used in Automotive Assembly

- Epoxy adhesives: High strength, excellent for aluminum bonding.

- Polyurethane adhesives: Flexibility under dynamic stress.

- Acrylic adhesives: Fast curing, moderate strength.

For product performance characteristics, visit epoxy adhesives used by industrial manufacturers.

Comparing Welding vs. Structural Adhesives in Aluminum Car Bodies

| Feature | Welding | Structural Adhesives |

|---|---|---|

| Weight Impact | Creates heavy seams, adds mass | Lightweight joints, reduces weight |

| Thermal Effects | Heat distortion, loss of strength | No thermal distortion |

| Corrosion Resistance | Risk at weld sites | Improved sealing, less corrosion |

| Assembly Speed | Slower, skilled labor required | Faster, easy automation |

| Durability | Prone to fatigue | Distributes stress, resists fatigue |

The Advantages of Structural Adhesive Bonding Over Welding

Enhanced Lightweighting and Fuel Efficiency

Adhesives create thin, lightweight joints, contributing to lower overall vehicle mass. This translates into better fuel efficiency and reduced CO2 emissions—major goals for modern automakers.

Superior Stress Distribution and Crash Safety

Unlike welds, adhesives spread loads over wider areas, minimizing localized stress and improving impact resistance. Crash tests repeatedly show that adhesive-bonded aluminum frames maintain integrity even under severe collisions.

Corrosion Prevention and Improved Car Longevity

Structural adhesives form a tight seal between aluminum sheets, blocking moisture intrusion and corrosive attack. This extends the lifespan of car bodies, especially in humid and coastal environments.

Process Efficiency and Automation Capability

Robotic application of adhesives enables high-speed, repeatable production. The ease of automating adhesive dispensing and curing supports just-in-time manufacturing and flexible assembly layouts.

Explore more on automotive adhesive manufacturing solutions for flexible production lines.

Challenges in Replacing Welding with Structural Adhesives

Surface Preparation Requirements

Aluminum’s oxide layer can inhibit adhesion. Proper cleaning, pretreatment, and primer usage are essential for strong bonds.

Reviewed in-depth at surface preparation techniques for adhesive strength.

Fixture Time and Curing Complexity

Structural adhesives require controlled curing—by time, temperature, or UV—before bonded parts reach load-bearing strength. This can create delays if processes aren’t optimized.

Inspection and Quality Assurance Differences

Evaluating welds is visual, but adhesive joints need peel, shear, and fatigue testing for assurance. New inspection tools are necessary for non-destructive quality checks.

Training and Process Adaptation

Shifting from welding to adhesives involves re-training technicians and redesigning assembly procedures.

Adhesive Chemistry: Tailoring Bonds for Aluminum Car Bodies

Epoxy Adhesives for High-Strength Applications

Epoxy adhesives excel in bonding aluminum, delivering bond strengths exceeding 25 MPa lap shear. Certain formulas offer long open times, fast fixture times, and resistance to hot/cold cycles.

Polyurethane and Acrylic Adhesives for Flexibility and Fast Curing

When assembly speed or dynamic joint flexibility is vital, polyurethanes and acrylics come into play.

Primers and Surface Modifiers

Primers and plasma treatments raise surface energy, boosting adhesive penetration and strength.

Real-World Case Studies: Automotive Manufacturers Using Structural Adhesives

The Tesla Model S and Model Y Platforms

Tesla’s pioneering use of aluminum panels with adhesives has contributed to class-leading lightweighting, high crash ratings, and streamlined assembly. The company adapted multi-material bonding, combining adhesive joints and spot welds where needed.

Jaguar Land Rover’s Bonded Aluminum Bodies

Jaguar Land Rover implemented strong adhesive bonding for its luxury sedans and SUVs. Their ‘body-in-white’ aluminum shells use adhesives for over 70% of joints, ensuring weight savings and superior noise isolation.

BMW’s Lightweight Bonding Technologies

BMW has adopted adhesives alongside rivets in its i-Series, realizing weight reduction and enhanced structural stability while maintaining crashworthiness.

Expert Opinions: The Future of Adhesive Bonding in Automotive

Assembly-Line Insights from ZDS Adhesive

ZDS Adhesive, an industrial adhesive manufacturer, highlights that the move to adhesives in aluminum car bodies requires strict attention to surface cleanliness, open time, and cure profile—especially in robotic assembly. Their engineers recommend lap shear and humidity cycling tests to validate bond integrity under real-world conditions.

Industry Trends and Material Innovations

Experts see growing demand for adhesives capable of bonding mixed materials—aluminum to steel, composites, and magnesium. Forward-thinking manufacturers focus on rapid-cure, high-peel strength formulas and predictive quality controls.

Processing and Application in Automotive Assembly Lines

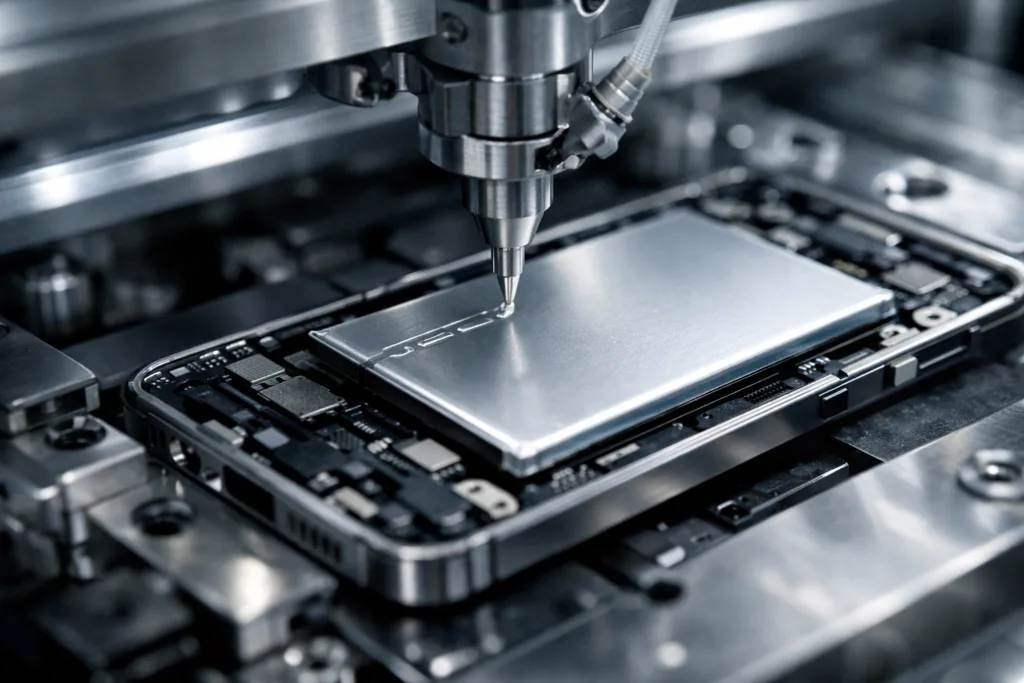

Robotic Dispensing Systems

Modern car plants rely on programmable robots to apply structural adhesives, ensuring consistent bead placement and volume.

Fixture and Cure Management

After adhesive application, components must be fixtured until cure completes. Temperature control, air flow, and part design all affect cycle time and throughput.

Quality Control and Testing Protocols for Adhesive Bonded Joints

Standard Testing Methods

- Lap shear

- Peel testing

- Thermal cycling

- Humidity aging

Non-Destructive Inspection Tools

Ultrasonic testing and optical systems allow manufacturers to evaluate bond lines without damaging assemblies.

Sustainability Impact and Lifecycle Benefits

Reducing Energy Consumption in Production

Replacing welding with adhesives cuts energy use, as no high-current welding or inert gas shielding is required during body assembly.

Trends in Recyclability and End-of-Life Disassembly

Adhesive choices increasingly consider end-of-life: reversible bonds, low-VOC formulas, and compatibility with recycling streams.

How Adhesives Improve Vehicle Performance and Customer Experience

Noise, Vibration, and Harshness (NVH) Optimization

Adhesive joints dampen vibration and road noise, offering smoother rides and quieter passenger cabins.

Boosting Durability for Extreme Environments

Vehicles exposed to salt, rain, or temperature swings benefit from sealed adhesive joints that ward off corrosion and fatigue.

Common Pitfalls and Solutions in Automotive Bonding

Preventing Adhesive Failure

Failures often stem from poor surface preparation, incorrect mix ratios, or inadequate curing conditions. Structured process controls and regular testing help ensure reliability.

Key Lessons Learned by Leading Manufacturers

Success stories reveal that developing clear assembly guidelines—such as required bond thickness and fixture times—minimizes risk and supports consistent output.

Replacing Welding with Structural Adhesives in Aluminum Car Bodies

The transition to adhesives has transformed automotive manufacturing by reducing mass, improving structural performance, and streamlining assembly. Ongoing innovation is pushing adhesives to operate in more extreme conditions and shorter cycle times—setting the bar for automotive joining in 2026 and beyond.

Conclusion: Practical Takeaways for 2026 and Beyond

Replacing welding with structural adhesives in aluminum car bodies is no longer a niche practice—it’s the new industry standard. For automakers and suppliers, the key is mastering adhesive selection, surface preparation, and process control. Manufacturers who invest in training, testing, and automation technology will realize lighter, stronger vehicles with better corrosion resistance and customer satisfaction. The future is adhesive—especially when reliable, sustainable performance is the end goal.

Frequently Asked Questions

Can structural adhesives fully replace welding in aluminum car bodies?

Structural adhesives can replace many welding joints, especially where stress distribution and corrosion resistance are essential. Some critical areas, like load-bearing chassis joins, may still require hybrid connections using rivets or spot welds for added security.

Do adhesive-bonded aluminum car bodies last longer?

Yes, adhesive bonding reduces corrosion and distributes stress, so vehicles often have longer service lives compared to welded bodies, especially in harsh climates.

Is adhesive bonding more sustainable than welding?

Adhesive-based assembly uses less energy than welding and can support future recycling initiatives, depending on adhesive chemistry and joint design.

What are some disadvantages of using structural adhesives?

Adhesive bonding requires precise surface preparation, curing time, and process control. Inspection methods for adhesive joints are more complex than visual weld checks, demanding advanced quality assurance tools.

Which automakers currently use adhesive bonding in aluminum car bodies?

Tesla, Jaguar Land Rover, and BMW all use structural adhesives in their aluminum car bodies, particularly in electric vehicles and premium models to reduce weight and improve durability.

Can adhesives bond aluminum to other materials?

Yes, modern structural adhesives can reliably bond aluminum to steel, composites, or other substrates, making them ideal for mixed-material automotive designs.

Related Reading

- Inside Automotive Assembly: Modern Adhesives versus Old Welding Methods

- Epoxy vs. Silicone vs. Polyurethane: Which Structurally Bonds Best?

- Avoiding Costly Bonding Failures: Lessons from Factory Floors

- Polyurethane Structural Adhesives for Demanding Automotive Joints

- What Sets ZDS Adhesive Solutions Apart in OEM Partnerships?