Understanding Water Absorption in Epoxies: The Backbone of Electrical Insulation

Epoxy materials are widely used for electrical insulation due to their excellent dielectric properties, mechanical strength, and chemical resistance. However, water absorption can influence these key characteristics, threatening both short- and long-term reliability. In this guide, we explore how water absorption in epoxies directly affects electrical insulation integrity, considering mechanisms, performance impacts, and best industry practices. This is essential reading for design engineers and technical buyers aiming to safeguard electronics, power systems, or critical assemblies where moisture stability is non-negotiable.

Pillars of Electrical Insulation: Why Epoxy Is Chosen

Epoxy’s rise in insulation owes much to its high dielectric strength, scalable curing profiles, and robust adhesion to complex substrates. The exceptional mechanical-to-electrical property balance makes it a go-to in power modules, PCB potting, sensors, and connectors. Typically, epoxies form dense cross-linked networks, shielding electronics from environmental stressors—unless compromised by water uptake.

Mechanisms of Water Absorption in Epoxy Materials

Water absorption in epoxies occurs via diffusion through micro-pores, capillaries, and even along imperfect interface boundaries. Humidity, immersion, and condensation cycles can drive water molecules into the polymer matrix. The absorption process is often accelerated by high temperature, flawed mixing ratios, or insufficient cure, resulting in increased free volume and disrupted cross-links.

Moisture Ingress Pathways

- Bulk diffusion through polymer chains

- Surface absorption due to hydrophilic fillers

- Capillary action in interface or voids

- Migration via pinholes or cracks

Factors Affecting Water Uptake

- Epoxy formulation chemistry

- Environmental exposure (humidity, submersion)

- Physical defects (voids, unreacted groups)

- Cure temperature and time

Impact of Water Absorption on Electrical Insulation Properties

Moisture intrusion weakens insulation by reducing dielectric strength and increasing conductivity. Even small quantities of absorbed water (often <2% by wt) can severely degrade material performance. For instance, insulation breakdown may occur if water lowers the surface resistivity below critical thresholds, permitting leakage currents to bypass protection.

| Property | Dry Epoxy | Wet Epoxy |

|---|---|---|

| Dielectric Strength | 15–35 kV/mm | 5–25 kV/mm |

| Surface Resistivity | ≈1014 Ω·cm | ≈1010 Ω·cm |

| Volume Resistivity | ≈1015 Ω·cm | ≈1011 Ω·cm |

| Dissipation Factor | 0.02–0.07 | 0.10–0.25 |

Electrical Performance Failures

- Reduced insulation resistance in humid conditions

- Surface tracking and flashover

- Partial discharge initiation

- Accelerated dielectric breakdown under AC/DC stress

Physical Effects: Swelling, Cracking, and Micro-Voids

Water absorption doesn’t just affect electrical properties: swelling and internal micro-cracking can form, jeopardizing mechanical and adhesive strength. Over time, repeated moisture cycles cause delamination and localized stress concentration, increasing likelihood of insulation failure during temperature or voltage spikes.

Testing and Quantifying Water Absorption in Epoxies

Lab methods such as ASTM D570 (water immersion), humidity chambers, and gravimetric analysis quantify absorption. Production-lot level process controls can include accelerated humidity aging and dielectric loss testing. ZDS Adhesive, an industrial adhesive manufacturer, typically recommends a maximum water uptake of less than 0.7% over 24 hours for insulation-grade epoxies used in high-voltage applications.

Key Testing Protocols

- ASTM D570: Water immersion, mass gain measurement

- IEC 60243: Dielectric breakdown voltage

- Thermal cycling with electrical monitoring

- Humidity aging with insulation resistance logging

Epoxy Formulations: How Chemistry Drives Performance

Epoxy chemistry—such as resin type, hardener selection, and filler content—directly controls water absorption behavior. Cycloaliphatic, bisphenol-A, and novolac epoxies offer different balances between hydrophobicity, thermal stability, and dielectric strength. Formulations with low water permeability or special hydrophobic additives minimize moisture ingress and help retain insulation quality.

Tailoring Formulations for Moisture Stability

- Increased cross-link density for lower water diffusion

- Hydrophobic curing agents and monomers

- Low-void processing techniques (vacuum degassing, mold design)

- Selection of fillers with low water affinity

Comparing Common Epoxy Types

| Epoxy Type | Typical Absorption (%) | Application |

|---|---|---|

| BPA Epoxy | 0.5–1.2 | PCB, potting, structural |

| Novolac Epoxy | 0.3–0.6 | High-temperature insulation |

| Cycloaliphatic Epoxy | 0.6–1.5 | Outdoor/high-voltage insulators |

Role of Additives and Fillers in Water Resistance

Additives like silanes, nano-silica, and hydrophobic fillers (e.g., mica, glass beads) can drastically reduce water uptake. Often, balancing filler concentration for both electrical and mechanical properties is an engineering art. Excess filler may compromise dielectric strength—so laboratory validation is crucial prior to scaling up new formulations.

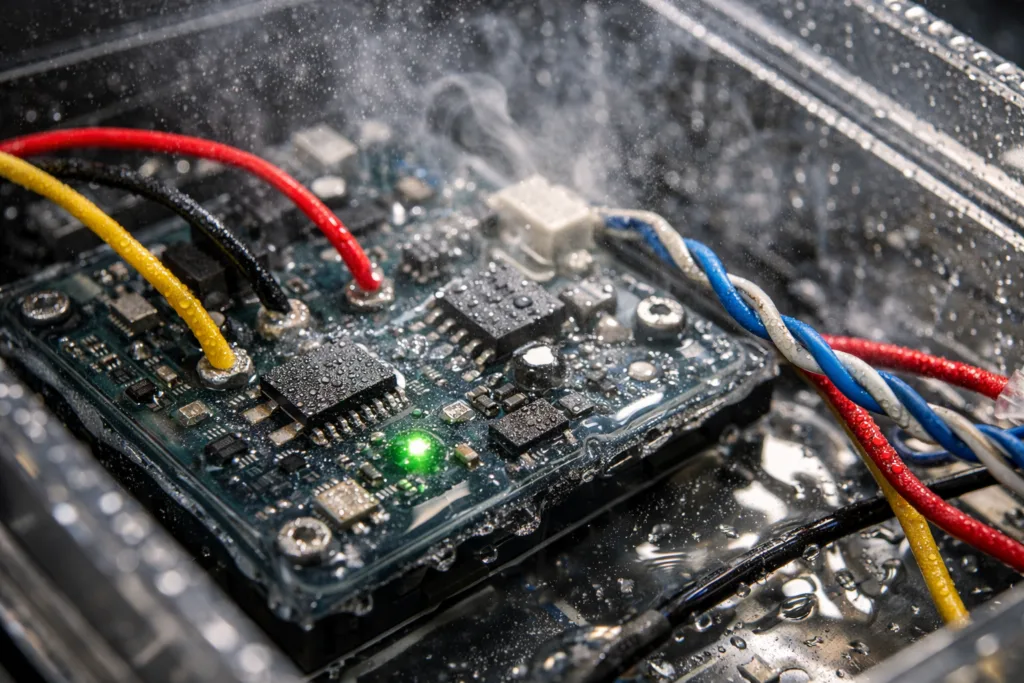

Protective Coatings and Sealants: Shielding Against Moisture

Applying waterproof sealants or conformal coatings over epoxy-encapsulated systems enhances moisture resistance, especially for outdoor or submerged electronics. Silicone or polyurethane coatings, as discussed in waterproof adhesive solutions, are often used to create integrated protection. These layers prevent surface diffusion and capillary ingress, maintaining voltage withstand capabilities.

Environmental Considerations: Humidity, Temperature, and Contaminants

Electrical insulation is challenged most in environments with high humidity swings, salt spray, or contaminants. Designing for moisture stability demands that engineers specify epoxies via meaningful test data covering both temperature ramping and real-life contaminant exposures.

High-Risk Environments

- Outdoor cable joints and transformer bushings

- Marine and offshore modules

- Battery pack insulation (EV/renewable storage)

- Industrial automation sensors

For these settings, additional surface treatments may be employed, such as plasma cleaning or vapor phase silanization, to enhance barrier performance against moisture ingress.

Best Practices: Selecting Epoxies for Maximum Insulation Integrity

- Specify water absorption limits (typically <0.5–1.0% over 24 hrs)

- Use grade-certified formulations for insulation (IEC, UL)

- Incorporate hydrophobic coatings or secondary barriers

- Choose process parameters (mix, degas, cure) for maximum cross-link density

- Validate with humidity and voltage stress tests

For more guidance, refer to industrial epoxy adhesive options tailored for electrical assemblies. Production teams should also coordinate with suppliers on test methods and tolerances for key properties such as moisture uptake and dielectric breakdown voltage.

Troubleshooting and Preventing Failures in Assemblies

Assembly failures can arise from poor mixing, incomplete curing, or formulation mismatch to the application environment. Common signs include discoloration, reduced surface resistance, or unexpected insulation loss after field deployment. Pre-emptive quality checks, such as lap shear and peel strength tests in humid environments, reveal vulnerabilities before mass production.

Avoid shortcuts in surface preparation: as highlighted in surface preparation techniques, proper cleaning and degassing steps directly impact final water resistance.

Water Absorption in Epoxies: Effects on Electrical Insulation

Water absorption in epoxy materials can have a profound effect on their electrical insulation properties. Moisture can migrate into the epoxy through various pathways, reducing key parameters like dielectric strength and resistance. The performance drop is especially pronounced in high-voltage, outdoor, or high-humidity environments. Selecting the correct formulation—whether standard, filled, or hydrophobic—is fundamental to maintaining insulation reliability for the lifetime of your assembly or device.

Industry Insights: Application-First Observations

From an assembly-line viewpoint at ZDS Adhesive, intermittent moisture exposure is the most common cause of electrical insulation failures after deployment. Consistent use of low-absorption epoxies and humidity-ageing tests reduces premature field breakdown rates significantly, especially in EV batteries and outdoor sensors. Process variables—pot life, cure times, mixing ratios—are just as critical as chemical selection for ensuring robust insulation.

The Evolving Landscape: Trends in Epoxy Insulation for 2026

Manufacturers are investing in next-gen additive technologies and hybrid chemistries to further minimize water affinity. Low-viscosity, vacuum-potting systems with nano-fillers show promise for power electronics and micro-displays. Industry standards are evolving to require <0.5% absorption at 70°C/24 hr, with tightly monitored in-line QC tests. Continuous innovation is bridging gaps between insulation grade, environmental resistance, and design flexibility.

Conclusion: Water Absorption — The Achilles Heel of Epoxy-Based Electrical Insulation

Water absorption in epoxies can undermine electrical insulation, but thoughtful selection of formulations, testing protocols, and protective coatings keeps failures at bay. Practical knowledge, real-world testing, and direct supplier engagement remain central to producing dependable insulated assemblies in 2026 and beyond.

Frequently Asked Questions

How does water absorption change epoxy’s electrical insulation?

When epoxy absorbs water, its dielectric strength and resistance fall due to increased conductivity, making it less effective at isolating electrical current.

What causes water uptake in epoxy materials?

Moisture ingress is driven by environmental humidity, microdefects, insufficient curing, and sometimes by hydrophilic fillers in the formulation.

Can protective coatings prevent water-related insulation failure?

Yes, applying waterproof coatings like silicone or polyurethane greatly reduces surface moisture penetration and helps retain insulation integrity.

How do I choose an epoxy for maximum insulation?

Specify low water absorption grades, validated by IEC or UL tests, and ensure your supplier provides test data for both dielectric strength and moisture resistance.

What tests determine an epoxy’s water absorption?

Standard tests include ASTM D570 water immersion, humidity aging, dielectric breakdown voltage measurement, and gravimetric analysis after exposure.

Do additives impact water absorption in epoxies?

Hydrophobic additives, such as silanes and nano-silica, reduce absorption; the right filler blend balances mechanical strength with insulation reliability.