Saltwater Resistance Testing for Marine Adhesives Explained

Saltwater environments present severe challenges to adhesive bonds, from relentless corrosion to aggressive chemical attack. Ensuring that marine adhesives resist degradation and maintain high durability under saltwater exposure is critical for shipbuilding, offshore wind, recreational boats, marine electronics, and harsh coastal applications. This article details the comprehensive saltwater resistance testing regimes used to qualify and validate marine adhesives—and how ZDS sets a benchmark for quality and reliability.

The Importance of Saltwater Resistant Marine Adhesive

Marine Adhesive Durability: Beyond Basic Water Resistance

Ordinary adhesives often fail in the presence of saltwater due to accelerated hydrolysis, metal ion migration, and substrate corrosion. Marine adhesives engineered for saltwater resistance incorporate advanced chemistries such as specialized epoxies, polyurethanes, acrylics, silicones, and hybrid systems. Their durability stems from molecular design, cross-link density, and robust interaction with marine substrates, all tested and verified using stringent laboratory procedures.

Target Applications for Saltwater Resistant Adhesives

- Boat hull and deck bonding (fiberglass, aluminum, composite)

- Marine hardware mounting (rails, cleats, hatches, fittings)

- Underwater electronics encapsulation and potting

- Dock, pier, and buoy assemblies

- Stone and tile installations on seawalls and coastal structures

Why Saltwater Resistance Testing Matters for Marine Adhesives

Saltwater Effects on Adhesive Bonding

Saltwater contains sodium chloride and trace minerals, introducing galvanic corrosion and osmotic stress to adhesive joints over time. These can lead to reduced lap-shear strength, loss of elasticity, surface pitting, and ultimate bond failure. Rigorous testing ensures adhesives meet required performance levels under prolonged exposure.

International Standards: ASTM B117 and ISO Compliance

The gold standard for saltwater exposure is the ASTM B117 salt spray (fog) test (ASTM D1002, ASTM B117), simulating continuous marine conditions for up to thousands of hours. ZDS marine adhesives are also validated to ISO 9001 protocols, with records traceable for regulatory and warranty requirements.

ZDS Saltwater Resistance Testing Workflow

Step 1: Substrate Preparation and Conditioning

- Degrease and abrade metal (aluminum, stainless steel), composite, or stone substrates using grit-blasting (recommended grit: 80–120).

- Apply adhesion promoters or primers (especially for engineered plastics: ABS, PC, PA, PP, using plasma/corona for surface energy boost).

- Condition substrates to controlled humidity (40–60% RH) before adhesive application.

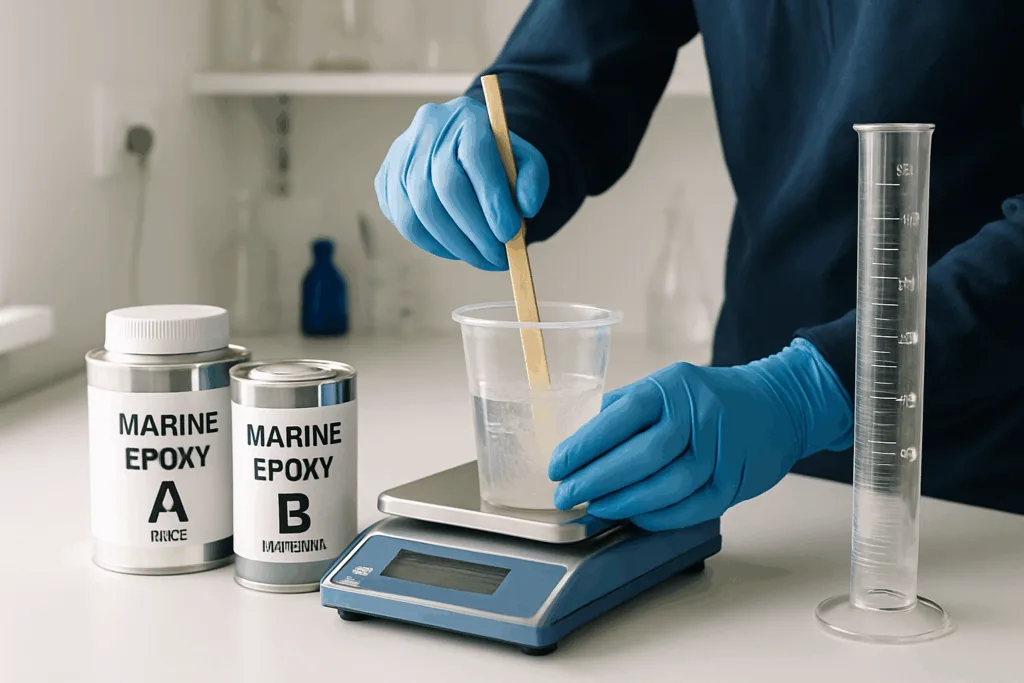

Step 2: Precision Adhesive Mixing and Application

- Mix 2K adhesives using static mixers or automated dispensing equipment. Typical mix ratios for marine epoxies: 100:40 resin to hardener (by weight).

- Monitor pot life (30–60 min for standard marine-grade epoxies) and open time to minimize premature cure or viscosity spike (cP monitoring).

- Apply adhesive via bead, slot-die, or notched-trowel process—ensure even bond-line thickness (recommended: 0.8–1.2 mm).

- Fixturing/clamping to achieve precise bond alignment during initial cure phase.

Step 3: Controlled Cure and Post-Cure

- Room-temperature cure (RT+24–48h) for most epoxies and MS hybrids; heat-accelerated cure (60–80°C/2–4h) for polyurethanes.

- Ensure full development of mechanical properties (Tg, Shore D hardness) before testing.

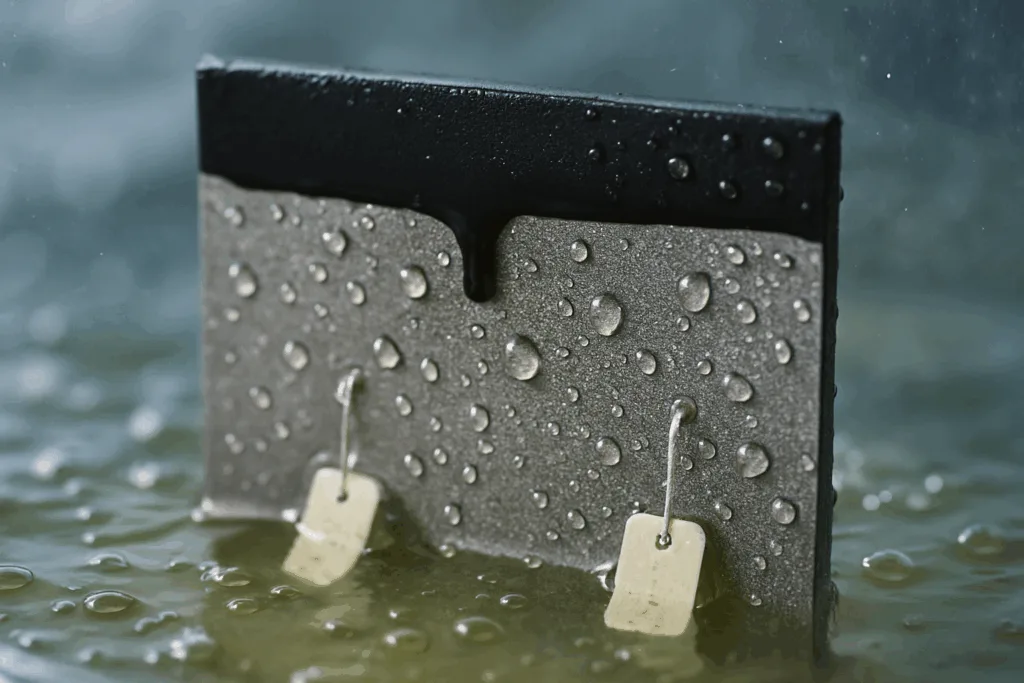

Step 4: Saltwater Exposure Protocols

- Place cured adhesive joints in a salt spray chamber (5% NaCl solution, ASTM B117) for intervals ranging from 500 to 2000 hours.

- Cyclic immersion: alternate between saltwater and atmospheric drying per ISO 16773 for real-world simulation.

- Monitor for white rust, surface blistering, delamination, or bond creep, with periodic mechanical testing.

Step 5: Durability and Failure Analysis

- Measure lap-shear strength (ASTM D1002), T-peel strength (ASTM D1876), and tensile properties post-exposure.

- Use cross-sectional microscopy and Shore A/D hardness testing to evaluate internal degradation.

- Document all results for traceability and QC compliance (REACH, RoHS, VOC).

Key Properties Assessed during Saltwater Resistance Testing

Mechanical Strength

Lap-shear failure thresholds for marine adhesives typically exceed 12 MPa after 1000+ hours salt spray, with minimal loss versus unexposed controls. T-peel retention above 90% of baseline is targeted for resilient adhesives.

Adhesion to Marine Substrates

- Performance on aluminum: strong corrosion and bond retention.

- Fiberglass composite: high shear, low creep, surface compatibility.

- Engineered plastics: require surface prep, primers, or plasma for optimal performance.

- Stone and ceramic: minimal chemical breakdown, high bond stability.

Thermal and Chemical Stability

Adhesives are cycled from -20°C to +80°C during testing, monitoring for exothermic breakdown, softening, or loss of modulus. ZDS solutions are formulated to resist UV, thermal, and chemical stress, ensuring longevity in dynamic marine conditions.

Saltwater Resistant Marine Adhesive Comparison Table

| Chemistry | Substrate Compatibility | Saltwater Resistance | Best Uses |

|---|---|---|---|

| Epoxy (2K) | Metals, composites, stone | Excellent (2000+ hr salt spray) | Hull bonding, structural joints |

| Polyurethane | Plastics, glass, metals | Good (1200+ hr exposure) | Deck joints, sealant/flex zones |

| Acrylic | Composites, plastics | Moderate (800–1000 hr) | Fittings, lightweight panels |

| Silicone | Glass, ceramics, plastics | Good (1200+ hr spray) | Electronics, watertight seals |

| Hybrid MS Polymer | Metals, plastic, stone | Very Good (1600+ hr) | Flexible trim, multi-material joints |

Factors Influencing Marine Adhesive Durability

Substrate Surface Preparation

Proper substrate cleaning and preparation (degreasing, abrasion, priming) are critical for maximum saltwater resistance. Insufficient prep leads to interfacial failure, while optimal surface energy and roughness enhance molecular adhesion.

Cure Regimen and Pot Life Controls

ZDS adhesives provide detailed recommendations for mix ratios, pot life, and cure time to ensure full cross-link density and long-term performance. Rapid cure or incomplete mixing can reduce saltwater resistance.

Adhesive Handling Best Practices

- Check viscosity at regular intervals during mixing (dynamic cP measurement)

- Use static or dynamic mixers for consistent blend

- Store unmixed components in humidity-controlled environments (5–25°C)

ZDS Quality Standards in Marine Adhesive Testing

Traceability, Certificates, and Compliance

Every batch of ZDS marine adhesive undergoes traceable QC checks aligned with ASTM and ISO 9001 standards. Safety Data Sheets (SDS), REACH, RoHS, and VOC documentation ensure compliance and global acceptance.

Manufacturing Insights from ZDS

“We rigorously validate marine adhesives in simulated salt spray chambers, mechanical testers, and cross-sectional microscopes to guarantee long-term durability—even after repeated thermal cycles and aggressive salt exposure.” — ZDS Technical Team

Automated Dispensing & Process Control

ZDS offers technical support for automated bead, slot-die, roll-coating, and spray processes—delivering consistent bond-lines with documented lot traceability for large marine projects.

Long-term Monitoring and Field Validation

Accelerated Aging vs. Real-World Feedback

Laboratory salt spray and immersion simulate years of field exposure in months. ZDS also supports field validation programs—sampling bonds from operational vessels, docks, or offshore turbines to confirm real-world performance metrics and continuous improvement.

Regular Maintenance Guidelines

- Inspect bonded joints annually for signs of surface pitting or blistering

- Perform touch-up applications in high stress or frequently submerged zones

- Track lot numbers and installation dates for warranty and insurance claim purposes

Choosing the Right Saltwater Resistant Marine Adhesive

Decision Criteria

- Substrate compatibility (epoxy for metal/stone, silicone for glass/plastic, MS for flexible joints)

- Required mechanical and peel strength (lap-shear target ≥12 MPa)

- Salt spray resistance (ASTM B117 hours rating)

- Cure time and environmental tolerance

- Regulatory and project documentation needs

Where ZDS Stands Out

ZDS assists with technical selection, precise mix ratios, and process setup for optimal saltwater resistant adhesive bonding—backed by documented test results, certificates, and global support.

Frequently Asked Questions

What does saltwater resistance testing involve for marine adhesives?

Saltwater resistance testing exposes bonded samples to controlled salt spray, immersion, and thermal cycling, measuring durability over time using international standards like ASTM B117.

How long do marine adhesives need to withstand saltwater exposure?

Marine adhesives are typically tested to withstand 500 to 2000 hours of continuous salt spray or immersion to simulate real-world marine environments and ensure lasting performance.

What factors influence marine adhesive durability in saltwater?

Key factors include adhesive chemistry, substrate preparation, cure regimen, bond-line thickness, and compliance with quality standards; these all affect resistance to saltwater attack.

Are ZDS marine adhesives certified for saltwater resistance?

Yes, ZDS adhesives are validated to ASTM, ISO 9001, REACH, and RoHS standards, with traceable QC records and certificates to guarantee saltwater resistance and regulatory compliance.

Which chemistry is best for saltwater resistant marine adhesive?

Epoxy-based adhesives provide superior saltwater resistance for metals and composites, while polyurethane and MS polymers excel for flexible or mixed-material marine bonding.

Can saltwater resistance be improved after adhesive application?

Although primary resistance is set during manufacturing and cure, annual inspection, touch-up application, and substrate reconditioning can extend durability of bonded marine joints.