The Future of Marine Adhesive Technology in 2025 and Beyond

Marine adhesive innovation is set to redefine bonding solutions for vessels and offshore structures in 2025 and beyond. Fresh technologies, stricter environmental standards, and shifting regulations challenge manufacturers to create safer, stronger, and more sustainable adhesives. From lightweight composites to evolving green chemistry, this field continues to push boundaries that benefit shipbuilders, repair yards, and marine equipment makers.

Emerging Marine Adhesive Innovations

Advanced Epoxy Formulations

Epoxy adhesives remain central in marine bonding for their toughness and resistance. In 2025, manufacturers tune formulations for faster cure times, lower exotherm (heat released during curing), and higher glass transition temperatures (Tg). This means adhesives perform better in hot climates, tolerate temperature swings, and bond a wider range of substrates, including steel, aluminum, composites, and engineered plastics like ABS (Acrylonitrile Butadiene Styrene).

Next-Generation Polyurethane Systems

Polyurethanes (often called “PU adhesives”) offer flexibility and shock absorption for hull seams and deck joints. Today’s research delivers one-component (1K) and two-component (2K) PU adhesives with improved moisture resistance. Their pot life and open time fit industrial assembly while maintaining strong bonds even after repeated salt spray exposure (tested per ASTM B117).

Hybrid MS Polymer Technology

MS (Modified Silane) hybrids combine the strength of polyurethane with silicone’s weather resilience. Adhesive brands now release MS polymers with enhanced UV stability, minimal shrinkage, and compliance with low-VOC (volatile organic compound) requirements. These innovations bring fast tack, wet surface bonding, and primer-free application to shipyards aiming to speed up production timelines.

Structural Acrylics and Fast-Cure Cyanoacrylates

Acrylic adhesives work well for joining metals found in superstructure or hardware. For rapid assembly, cyanoacrylates (often called “CA adhesives”) offer instant bonding for emergency repairs. Manufacturers adjust cure kinetics and viscosity (measured in centipoise, cP) for syringe, bead, and spray application across smooth and porous surfaces.

Marine Adhesive Trends Shaping Tomorrow

Sustainability and Bio-Based Adhesives

Shipbuilders and marine equipment firms increasingly consider sustainability. In 2025, the market grows for adhesives from renewable sources—plant oils, bio-polymers, and recycled feedstock. These formulations cut the carbon footprint and ease compliance with new global standards like REACH and RoHS.

Low-Emission and VOC-Free Systems

Low-emission adhesives minimize volatile organic compounds (VOCs). This improves air quality in enclosed spaces such as ship cabins and reduces environmental impact during manufacturing and application. ZDS leads development of tape and film-based marine adhesives that meet strict VOC limits, offering safe indoor installation and reliable, long-lasting bonds.

Eco-Friendly Packaging and Process Automation

Innovators now design bulk packaging that cuts waste and limits solvent exposure onsite. With precision dispensing—bead, slot-die, and roll-coat—marine assembly lines automate adhesive application to ensure consistent bond lines and reduce operator risk.

Regulatory Changes Affecting Marine Adhesives

Tighter Rules on Emissions and Chemical Safety

Global marine markets are subject to new health and safety regulations targeting hazardous substances. Standards including ISO 9001 for quality management and SDS (Safety Data Sheets) ensure factories track every adhesive batch, document hazards, and meet maritime compliance. Shipbuilders must select adhesives certified for below-deck fire and smoke performance.

Sustainability Certifications and Life-Cycle Analysis

Adhesive suppliers are now requested to provide environmental product declarations (EPDs) and undergo life-cycle analysis (LCA). This ensures that adhesive systems remain transparent about raw materials, waste treatment, and environmental impacts throughout the vessel’s lifespan.

Manufacturing Insights From Adhesive Experts

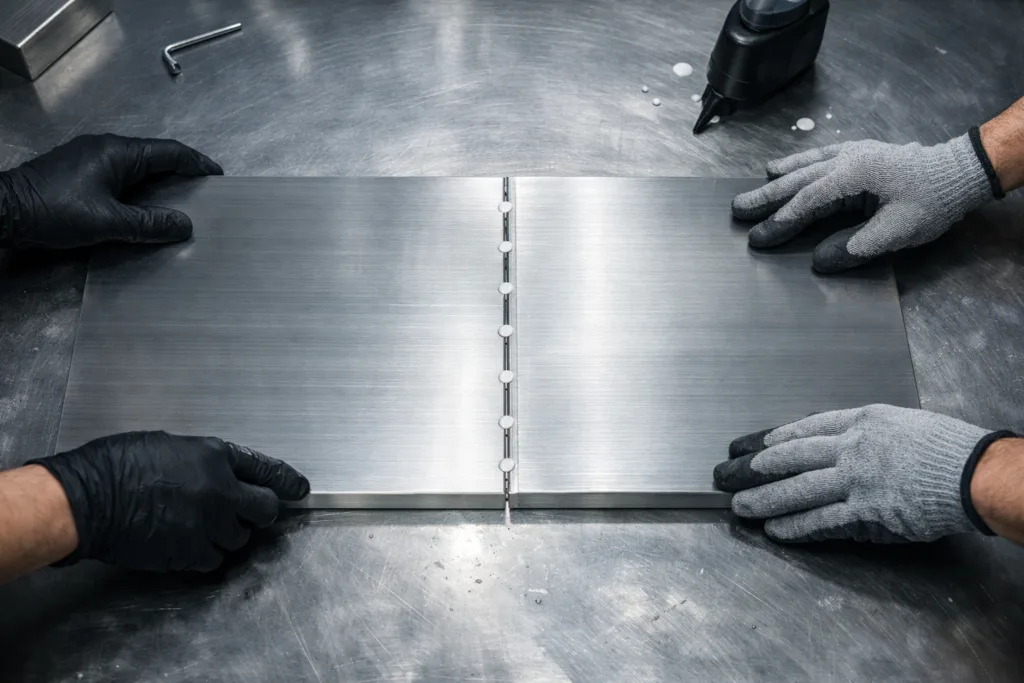

Preparing Marine Substrates for Bonding

Successful marine adhesive bonding starts with proper surface preparation. Metals need to be degreased, abraded, and often grit-blasted to improve adhesion. Composites and plastics such as PC (polycarbonate) or PP (polypropylene) may require corona or plasma treatment and specialized primers. Stone, glass, and ceramics benefit from adhesion promoters to optimize bond strength and durability.

Processing Marine Adhesives

Adhesive application methods—bead, spray, notched trowel, roll-coat—are chosen based on vessel part geometry and material type. Mixing two-component adhesives accurately is critical: manufacturers specify mix ratios, use static mixers, and automate dispensing to prevent cure issues and strength loss.

Testing and Quality Control

Performance validation relies on standardized tests. Lap-shear strength (per ASTM D1002), T-peel (ASTM D1876), and tensile measurements ensure adhesives withstand marine stresses. Aging and thermal cycling simulate years at sea. Adhesives pass salt spray tests and meet documentation for REACH, RoHS, and major maritime standards.

Comparing Marine Adhesive Systems

| Chemistry | Common Substrates | Key Properties | Best Uses |

|---|---|---|---|

| Epoxy | Metal, composite, glass | High shear, chemical resistance, heat tolerance | Hull bonding, structural joints |

| Polyurethane | Composites, plastics, stone | Flexibility, moisture/UV resistance | Deck seams, expansion joints |

| Acrylic | Metal, plastic | Fast cure, impact resistance | Assembly, hardware mounting |

| Silicone | Glass, ceramics, metals | Extreme temp, waterproof | Sealant, weatherproofing |

| Hybrid MS | Multiple, incl. painted surfaces | Low shrinkage, primer-free, VOC safe | Interior/exterior bonding |

| Cyanoacrylate | Plastic, rubber, metal | Instant bond, small repairs | Emergency fixes, equipment |

| Tape/Film | Panels, insulation, electronics | Easy, clean application | Bulkhead, non-structural |

Smart Marine Adhesive Selection Process

Assessing Performance Requirements

Choosing the right adhesive starts by defining joint loads, exposure cycles, and substrate combinations. Consider lap-shear ratings in MPa, temperature range, and salt spray resistance. For structural areas, prioritize adhesives with proven test data and marine certifications.

Custom Solutions for Shipbuilders

Modern shipyards often need custom adhesives engineered for complex assemblies. ZDS works with researchers and manufacturers to optimize formulation, packaging, dispensing, and cure profiles to fit production targets and environmental needs.

Optimizing for Compliance

It is vital to choose adhesives documented for regulatory compliance. Shipyards benefit from suppliers that offer traceability, clear SDS, and tested conformity with maritime environmental and safety standards.

Marine Adhesive Innovation Driving Sustainability

Recyclable and Removable Adhesive Solutions

Future marine adhesives are not only strong but also designed for de-bonding. Removable tapes and thermally reversible adhesives support ship refit, repair, and end-of-life recycling.

Robotic and Automated Dispensing Systems

Digital dosing and closed-loop monitoring improve efficiency. Shipbuilders implement automated mix and dispense stations for large structural bonds and electronics potting, guaranteeing precise application and reducing waste.

- Reduced training needs

- Improved consistency

- Lower material loss

Clean Manufacturing for a Greener Marine Industry

From water-based primers to low-solvent adhesives, the marine sector shifts toward clean production. ZDS continues investment in non-flammable, low-odor chemistries that meet shipboard worker safety standards.

Marine Adhesive Trends in Compliance and Documentation

Salt Spray and Aging Tests

Every marine adhesive undergoes accelerated salt spray and aging (using ASTM B117 and climatic chambers) to ensure durability. Shipbuilders receive traceability on lot numbers and access to audited documentation for every delivery batch.

Thermal Cycling and Flexibility Analysis

Critical joints in ships experience repeated heating and cooling. Adhesives are tested for thermal cycling and report hardener (cure speed), exotherm, and stress-crack resistance metrics. Analytical labs measure Shore hardness to rate bond robustness.

Digital Documentation and Global Shipping Traceability

Each adhesive’s SDS and compliance certificates move digital. Shipbuilders use QR codes and secure portals for instant access to technical data, streamlining inspection and audit processes before sailing.

Industry Outlook: Opportunities and Strategies for 2025

Growth in Composite Shipbuilding

Lightweight composites dominate new ship and yacht builds. Adhesives engineered to bond carbon fiber, glass-reinforced plastic (GRP), and sandwich panels replace outdated welding, offering speed and corrosion resistance.

Marine Repairs and Maintenance

Innovative adhesives play a key role in fast repairs—patching hulls, reinforcing deck fixtures, or waterproofing compartments. Emergency CA systems and quick-cure acrylics keep vessels operational with minimal downtime.

Waste Reduction and Recycling in Marine Adhesives

Manufacturers adopt reusable cartridges, recyclable pouches, and solvent-free cleanup practices. Adhesive waste management ties into broader shipyard efforts for energy, water, and environmental footprint reduction.

Expert Insight: Investing in sustainable marine adhesives boosts regulatory compliance, reduces warranty claims, and improves worker safety. The future points toward advanced chemistries, automation, and documentation standards like never before.

Frequently Asked Questions

What is marine adhesive innovation?

Marine adhesive innovation involves developing new chemistries and solutions that provide stronger, safer, and eco-friendly bonding for ships and offshore structures.

How do marine adhesive trends affect shipbuilders?

Emerging trends favor adhesives with faster cures, better durability, and lower environmental impact, helping shipbuilders meet stricter regulations and optimize workflows.

What are the main regulations for marine adhesives in 2025?

Key regulations include VOC limits, ISO 9001, REACH, RoHS, and fire/smoke safety standards for below-deck adhesives used in marine applications.

How does sustainability shape marine adhesives?

Sustainability drives the shift to bio-based, recyclable, and VOC-free adhesives, lowering the environmental footprint of shipbuilding and repair activities.

What substrates can marine adhesives bond?

Marine adhesives bond metals, composites, plastics, glass, ceramics, and stones, often requiring degreasing and surface treatments to maximize adhesion.

Why choose ZDS for marine adhesive solutions?

ZDS offers advanced, compliant marine adhesives for structural and non-structural applications, plus custom support for shipbuilders and maintenance teams.