Understanding Industrial Adhesives for Plastic (PP, PE, ABS, PVC)

Industrial adhesives for plastic bonding play a key role in modern manufacturing. Materials like polypropylene (PP), polyethylene (PE), acrylonitrile butadiene styrene (ABS), and polyvinyl chloride (PVC) each offer distinct properties, but they pose challenges for reliable joining. Low surface energy makes many plastics—especially PP and PE—very tough to bond without the right preparation or adhesives. Knowing how to choose, prep, and apply industrial plastic adhesive ensures strong, repeatable results and durable assemblies.

The Challenge of Low Surface Energy Plastics

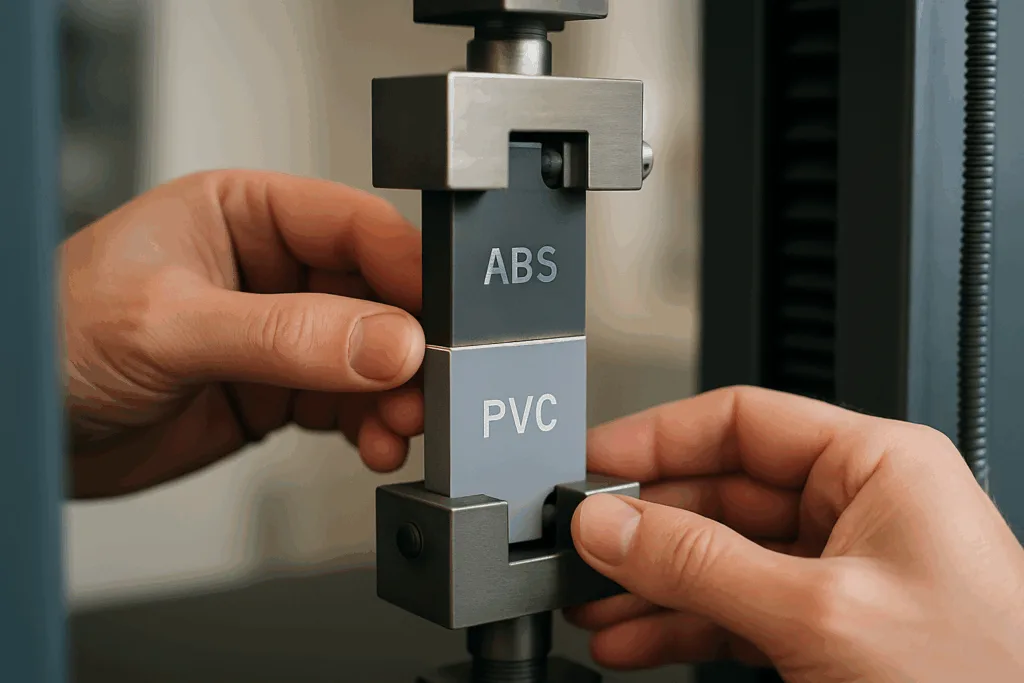

Bonding plastics such as PP and PE is notoriously difficult. These materials have low surface energy, meaning adhesives tend to “bead up” rather than spread and penetrate. Without surface activation, many standard adhesives simply peel away. By contrast, ABS and PVC have higher surface energy and offer more options for secure bonding but still require tailored adhesive selection for stress, flexibility, and chemical resistance needs. Engineers must address these challenges head-on to achieve high strength and long life in plastic assemblies.

Key Properties of Target Plastics

- PP (Polypropylene): Low density, chemical resistance, slick surface, hard to bond.

- PE (Polyethylene): Similar to PP, low friction and high impact properties, very low energy surface.

- ABS: Higher energy, rigid, easy to process, good impact performance, moderate chemical resistance.

- PVC: Available rigid or flexible, good adhesion, widely used for pipes, fittings, sheets, and cable sheaths.

Plastic Bonding Performance Metrics

Performance of industrial plastic adhesive depends on a few key factors:

- Lap Shear Strength: Measures adhesive strength between overlapped parts (ASTM D1002).

- T-Peel Strength: Evaluates how easily bonded strips can be pulled apart (ASTM D1876).

- Temperature/UV/Chemical Resistance: Adhesive must withstand actual service conditions—heat, solvents, outdoor exposure, cleaning cycles.

- Elongation and Flexibility: Especially important for plastics that flex or vibrate in use.

Surface Treatment Methods for Reliable Plastic Bonding

Proper surface treatment transforms difficult-to-bond plastics into receptive substrates for adhesives. For PP and PE, the right preparation makes all the difference. Below are the most effective methods for industrial applications:

- Chemical Primers: Special adhesion promoters or primers react with the plastic surface, making it more “wettable” for adhesives. Popular for both PP and PE.

- Corona Treatment: High-voltage discharge roughens and oxidizes the plastic surface at a molecular level. Ideal for sheet, film, and extrusion operations. This method is fast but may lose effectiveness over time if bonding is not done soon after treatment.

- Plasma Treatment: Uses ionized gas to bombard the surface, dramatically boosting bond strength, especially for medical, automotive, and electronic plastics.

- Abrasion: Mechanical roughening (sanding, grit-blasting) increases surface area and creates micro-anchoring points—works best on rigid plastics like ABS or PVC.

- Degreasing: Always clean the surface with isopropanol or recommended solvents. Oils and mold release agents can prevent adhesive for plastic bonding from working as intended.

Expert Tip: Always combine mechanical and chemical surface prep where maximum bond strength is critical. Quick test: a wetted adhesive bead should spread and not “ball up”—a good sign of activated surface.

Overview: Adhesive Chemistries for Plastic Bonding

Each class of industrial plastic adhesive has benefits and trade-offs. The best choice depends on cost, process, and end-use requirements. The table below compares major adhesive types across these plastics.

| Adhesive Chemistry | Plastics Suited | Cure Method | Best Properties | Best Use Cases |

|---|---|---|---|---|

| Epoxy (1K/2K) | ABS, PVC, (with primer: PP, PE) | Room temp, heat, UV | High strength, chemical/heat resistance | Automotive, electronics, appliances |

| Polyurethane (PU) | ABS, PVC, PP, PE (with primer) | RT/moisture | Flexibility, weather resistance | Assembly, panels, outdoor |

| Acrylic (MMA) | ABS, PVC, PP, PE (no/low prep) | RT/UV | Gap fill, impact resistance | Signage, displays |

| Cyanoacrylate (CA) | ABS, PVC, some PP/PE (with primer) | RT instant | Speed, clear bond | Small parts, field repair |

| Silicone/Hybrid MS | PVC, some ABS, PP/PE (with primer) | RT/moisture | Flexibility, tough environments | Sealing, vibration, thermal cycling |

| Pressure-Sensitive Tape | All (with tailored adhesives) | N/A | Clean, fast, reworkable | Electronics, trims, temporary fixturing |

Best Adhesives for PP and PE Bonding

Polypropylene (PP) and polyethylene (PE) are among the toughest plastics to bond. Their waxy, non-polar surfaces resist most common adhesives. However, advances in formulation and surface prep open up new options for industrial plastic adhesive applications.

Two-Part Acrylics (MMA)

Modern methyl methacrylate (MMA) adhesives can bond PP and PE with little or no surface treatment. These adhesives tolerate oily surfaces and offer high lap-shear strength (often 6–14 MPa on PP or PE, ASTM D1002). Pot life ranges from 2 to 12 minutes, with functional cures within the hour. Their high elongation & impact resistance suit automotive fascias, bumpers, and industrial panels.

Polyurethane Adhesives

Flexible polyurethane adhesives excel in bonding low-energy plastics, especially after primer or plasma treatment. They offer resilience for assemblies exposed to vibration or movement. Shore A hardness values can be tuned for soft or firm flexible bonds.

Hot-Melt and Reactive Hot-Melt Adhesives

For mass production (packaging, automotive interiors), hot-melts and reactive PUR hot-melts bond PE/PP quickly. Modern grades offer set times under 10 seconds, high production throughput, and strong resistance to water and chemicals.

Adhesion Promoters and Surface Primers

When using epoxies, cyanoacrylates, or even tapes, specialty primers can often double or triple bond strength. Proper compatibility testing is essential—always check spray or brush-on primer is matched to adhesive chemistry and substrate.

Best Adhesives for ABS and PVC Bonding

ABS and PVC are more forgiving when bonding thanks to higher surface energy. But process and end-use conditions still dictate the best industrial adhesive.

Epoxy Adhesives

1K and 2K epoxies are popular for ABS and rigid PVC, providing high load-bearing strength, chemical durability, and bonds that resist creep. For applications with higher temperature requirements (up to 120°C service), toughened or filled epoxies are preferred. Mix ratios and working times vary by product—common pot lives range 5–30 minutes; full cure by 24 hours at room temperature.

Cyanoacrylate “Super Glue” Adhesives

CA adhesives rapidly bond ABS and PVC in seconds, making them ideal for small parts or quick repairs. They deliver lap-shear strengths up to 7 MPa (on ABS), but may become brittle under shock or vibration. Select specialty formulations with elastomeric modifiers for improved impact performance.

Contact Cements and Solvent Cements

For PVC, solvent-based cements dissolve and fuse surfaces for a true weld. These cements are standard in piping and conduit assembly. Always use in a well-ventilated area as many contain strong solvents.

Pressure-Sensitive Tapes

High-performance double-sided tapes—often acrylic foam or rubber-based—offer fast, uniform bonding for signage, panels, and trim. ZDS provides tape and films engineered for consistently high peel and shear on ABS/PVC, including automotive approved grades.

How to Apply Industrial Plastic Adhesive for Reliable Results

Every successful plastic bonding step counts. Follow these guidelines for optimal bond integrity and process control:

- Surface Preparation: Clean and activate as needed; allow primers to flash off per supplier specs.

- Dispensing: Use static mixers or precision dispensers to ensure correct mix ratios and uniform bead application for 2K systems.

- Fixturing: Clamp or fixture parts to maintain pressure during initial cure; avoid excessive squeeze-out.

- Cure Time: Respect open and working times; do not disturb during initial set. Full mechanical performance may develop over 24–48 hours.

- Quality Control: Test bonds per ASTM D1002 (lap shear) or manufacturer recommendations. ZDS offers guidance on process QC and lot traceability for critical assemblies.

Industrial Adhesives for Plastic (PP, PE, ABS, PVC)

Choosing the right adhesive for plastic bonding is about more than product data. It requires understanding the specific substrate, process, and application needs. ZDS supports customers with a full portfolio: epoxies, polyurethanes, acrylics, silicones, cyanoacrylates, hybrid MS, and engineered tapes. Whether bonding lightweight automotive facias, constructing electronic shells, or sealing industrial enclosures, ZDS’s technical support can guide substrate prep, joint design, and process controls for optimal field durability.

Process Validation, Standards, and Compliance in Plastic Bonding

Industrial bonding must meet strict QC and regulatory standards. Bonded plastic assemblies often undergo salt spray (ASTM B117), thermal cycling, and aging tests to ensure reliability. ZDS adheres to REACH, RoHS, and VOC requirements and provides full SDS and ISO 9001 production traceability. Proper storage (typically 5–25°C, dry, dark) and stock rotation are critical to maintaining adhesive performance.

Trends: Innovations in Plastic Bonding Adhesives

Recent developments include:

- Primerless Bonding: Next-generation acrylics and polyurethanes delivering robust bonds without costly surface treatment—accelerating production lines.

- UV/Light-Cure Systems: High-speed assembly adhesives with instant cure, ideal for electronics and optics.

- Smart Adhesives: Incorporating indicators for complete cure or quality verification.

- Bio-Based Adhesives: Growing interest for eco-friendly assemblies in consumer goods and automotive interiors.

Making the Right Choice: Selecting an Industrial Plastic Adhesive

The optimal adhesive for plastic bonding always depends on your application’s priorities—strength, speed, flexibility, durability, or appearance. Consult adhesive suppliers early in design to validate joint geometry, process compatibility, and compliance with required standards. Consider batch testing and pilot runs before large-scale roll-out for best results.

Frequently Asked Questions

What makes PP and PE difficult to bond?

PP and PE have low surface energy, so most adhesives cannot adhere well without surface treatment or special primers designed for these plastics.

How can I improve adhesive strength on plastics?

Use surface treatments like corona, plasma, abrasion, or primers to increase surface energy and allow adhesives to spread and anchor properly.

Which adhesives work best for ABS?

Epoxies, cyanoacrylates, and some acrylics are well-suited for ABS, providing high strength and compatibility with minimal prep.

Are primerless adhesives available for plastic bonding?

Yes, some new acrylic and polyurethane adhesives can bond low energy plastics like PP or PE without primers, though performance may vary.

Why is surface cleaning important before bonding?

Oils, dust, and release agents prevent good adhesive contact; thorough cleaning removes barriers, allowing for reliable, consistent bonding.

How should adhesive bonds be tested for quality?

Industry standard tests like ASTM D1002 for lap shear and peel tests verify bond strength. Always test under realistic end-use conditions.