Introduction: Understanding PCB Protection — Conformal Coating vs. Potting Compound

In electronics manufacturing, protecting printed circuit boards (PCBs) is essential for reliability—especially in harsh environments. Two leading methods stand out: conformal coating and potting compound. Both shield PCBs from moisture, dust, and chemicals, but their performance, process, and field suitability differ. This ultimate comparison dives deep into how each technique works, their crucial differences, and when to use each approach. Real-world examples, expert perspectives, and industry insights will guide you toward the most effective decision for your electronic assemblies.

What Is Conformal Coating?

A conformal coating is a thin, protective film applied over PCB assemblies. It’s designed to ‘conform’ to component shapes, delivering a barrier against moisture, contaminants, and electrical shorts without adding significant weight or bulk. Typical coating materials include acrylics, silicones, polyurethanes, and epoxies—each with specific advantages for temperature performance, chemical resistance, and reworkability.

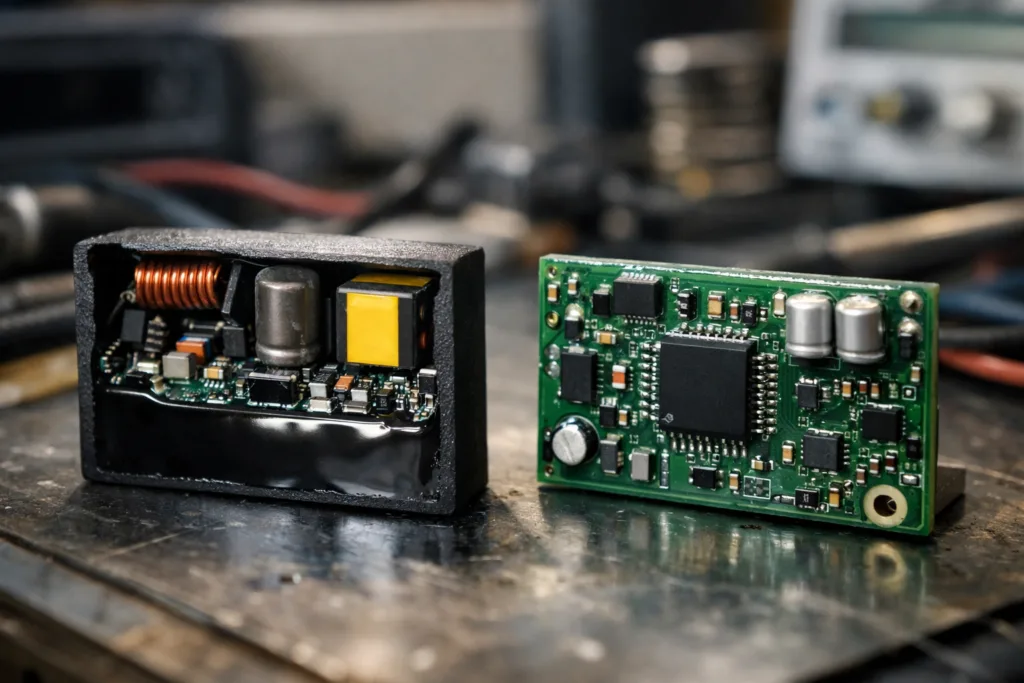

What Is Potting Compound?

Potting compound refers to a process of completely encapsulating PCBs or electronic assemblies within a thick layer of protective resin. Unlike the surface-only protection of conformal coatings, potting forms a solid, robust barrier totally sealing components from their environment. Common potting chemistries include epoxy, polyurethane, and silicone, each tailored for specific mechanical and thermal demands.

Key Differences Between Conformal Coating and Potting

The main contrast lies in the application and physical protection offered:

- Layer thickness: Conformal coatings are ultra-thin (25–250 μm); potting compounds are much thicker (up to several millimeters).

- Circuit accessibility: Coatings can be easily removed and repaired; potted assemblies are generally permanent and harder to access.

- Mechanical strength: Potting offers mechanical reinforcement; coatings only insulate.

- Mass/footprint: Coatings add minimal bulk, ideal for compact electronics; potting increases part size and weight.

Comparison Table: Conformal Coating vs. Potting Compound

| Feature | Conformal Coating | Potting Compound |

|---|---|---|

| Layer Thickness | 25–250 μm | 1–15 mm+ |

| Repairability | Simple (can be reworked) | Difficult (often destructive) |

| Mechanical Protection | Low | High (vibration, impact) |

| Environmental Resistance | Good | Excellent |

| Thermal Management | Limited | Superior |

| Electrical Insulation | Good | Excellent |

| Cost | Lower | Higher |

Applications of Conformal Coating

Conformal coatings are a staple for PCBs in automotive, aerospace, telecommunications, LED lighting, wearable devices, and consumer electronics. They shine where moderate protection is needed without major impact on part dimensions or weight. For instance, automotive electronics exposed to humidity and dust, but not directly submerged, benefit from conformal coatings. Wearable devices—like smartwatches or fitness trackers—use coatings to defend delicate circuitry while keeping enclosures slim and lightweight.

Applications of Potting Compound

Potting compounds feature prominently in high-reliability environments—think industrial sensors exposed to constant vibration, motors, power supplies, high-voltage battery packs, and outdoor LED drivers. Potted assemblies withstand extreme temperature cycles, chemical splashes, and prolonged outdoor exposure. For example, battery modules in electric vehicles often require potting for impact and fire resistance (as detailed in this expert guide comparing silicone and polyurethane potting for battery modules).

Material Types: Chemistry Breakdown

Acrylics

Popular for conformal coatings due to quick drying, clarity, and easy rework.

Polyurethanes

Offer great chemical and moisture resistance; used in both coatings and potting, especially for automotive and industrial applications. Custom polyurethane potting glue solutions are growing in popularity.

Silicones

Resilient in extreme temperatures, making them ideal for power modules and outdoor applications.

Epoxies

Outstanding mechanical strength and permanent bonds, suitable for severe environments and high-voltage insulation (learn more about industrial-grade epoxy adhesives here).

Advantages of Conformal Coating

- Lightweight and minimal space consumption

- Easy inspection and rework

- Cost-effective for high-volume production

- Clear coatings for LED/lens applications

Advantages of Potting Compound

- Superior protection (mechanical, chemical, electrical)

- Excellent for outdoor or submerged applications

- Thermal management with filled compounds

- Anti-tamper and anti-vibration design

Limitations of Conformal Coating

- Does not protect against severe mechanical shock

- Less robust in fully immersed/waterlogged situations

- Limited thermal dissipation

Limitations of Potting Compound

- Increases part size and weight

- Hard or impossible to repair or inspect

- Higher material cost and longer curing

Environmental Suitability: Choosing for Exposure Risks

When selecting between these two methods, consider the exposure level. For moderate humidity or dust, conformal coating suffices. For harsh outdoor, high-vibration, or hazardous chemical exposure, potting is the robust choice.

Thermal Management Considerations

Thermally conductive potting compounds efficiently draw heat away from power components, extending lifespan. Conformal coatings only provide basic protection but do little to manage hotspots. Need more details on thermal interface materials? This engineer’s guide to gap fillers breaks it down further.

Repairability and Field Service

Conformal coatings are usually removable, allowing field repairs and quick rework. Potting immobilizes the assembly, so repairs are costly or impossible without destroying the potted mass. Serviceability is key for products with field upgrades or warranty repair requirements.

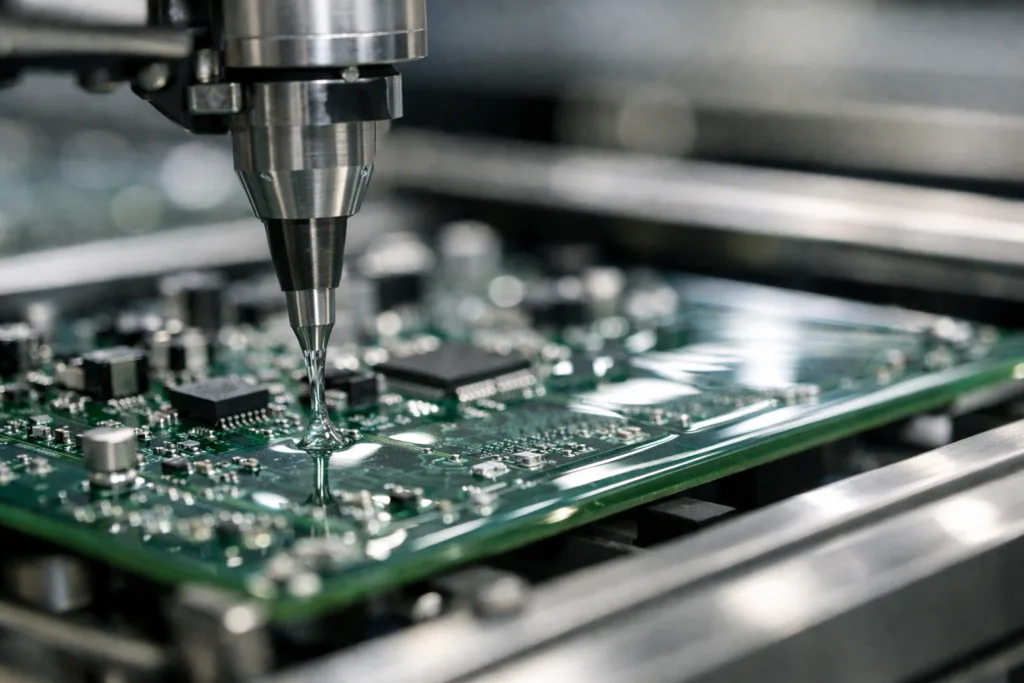

Process, Equipment, and Throughput

Spraying, brushing, or dipping apply conformal coatings for rapid throughput and scalable automation. Potting, however, needs measured dispensing, degassing, and extended cure times, which can affect production schedules and increases cost for high-volume manufacturing.

Cost Analysis: Material and Lifecycle Economics

Upfront, conformal coatings are more cost-effective—lower material and labor inputs. Potting has higher initial costs but may deliver ROI by preventing catastrophic failures in critical environments where board replacement is much more expensive than repair.

Case Studies: Real-World Solutions

Automotive Sensor Modules

Vibration and chemical attack are concerns—here, polyurethane potting compounds outperform coatings by preventing PCB fatigue and corrosion.

Wearable Medical Devices

Space and weight matters, but high moisture resistance is needed. Silicone conformal coatings offer enough intrusion protection, and are serviceable during R&D changes.

Outdoor LED Lighting Drivers

Sustained exposure to rain, UV, and dust—potting compounds ensure longevity, maintain insulation, and survive thermal cycling.

Expert Opinions: Lessons from Application Engineering

From an assembly-line viewpoint at ZDS Adhesive, an industrial adhesive manufacturer, the proper selection comes down to environment severity, need for field repair, and total life-cycle cost. Their engineers recommend a simple flowchart: if mechanical shock risk or full submersion, choose potting; if space, weight, or rework are key, go coating. Substrate compatibility and desired cure speed should also be evaluated during line trials—moisture-cure silicones handle plastics and metals, while UV-cure acrylics fit lean, fast-moving lines.

Which Should You Choose? Checklist for Selection

- Need minimal mass, easy rework? → Conformal coating

- Exposed to vibration/chemicals? → Potting compound

- Thermal hot spots? → Filled potting resin

- High production rate, thin boards? → Conformal coating

- Perimeter sealing required? → Potting compound

Conformal Coating, Potting Compound

These two protective methods—conformal coating and potting compound—address very different challenges. In practical experience, coatings fulfill everyday needs in consumer, telecommunication, and some automotive devices, keeping boards slim and accessible. Potting compounds, however, are the gold standard in hostile environments, where failure is not an option, like power electronics, industrial equipment, or mission-critical automotive modules. Modern manufacturing often even combines both, using selective coating plus localized potting for best-in-class protection.

Conclusion: Making a Smart PCB Protection Choice

Both conformal coating and potting compound are vital to safeguarding electronics, but the right solution hinges on your risk profile, operating environment, and product lifecycle goals. Use coatings for convenience and serviceability, potting for long-term, high-stress durability—and always consult technical experts before finalizing materials. Smart selection secures not just your PCBs, but your reputation for reliability in 2026 and beyond.

Frequently Asked Questions

When should I choose potting over conformal coating?

Potting is best for extreme environments where the PCB requires robust mechanical, chemical, or water protection, or when anti-tamper features are needed.

Can conformal coating be removed for repairs or upgrades?

Yes, most conformal coatings can be removed using special solvents or mechanical abrasion, making them suitable for field repairs or design changes.

What are the main disadvantages of potting compounds?

Potting increases weight and prevents easy inspection or repair. Removal is difficult and sometimes can damage components or boards.

Does potting improve heat management for electronic assemblies?

Thermally conductive potting compounds help dissipate heat away from sensitive components, preventing hot spots and prolonging lifespan.

Which method is more cost-effective for large volume production?

Conformal coatings are more cost-effective due to lower material and labor input, especially for products where moderate protection suffices.

Can I use both conformal coating and potting on the same assembly?

Yes. Many designs combine selective coating with localized potting to balance protection, serviceability, and cost for complex builds.

Related Reading

- How Reworkable Underfill Rescues Smartphone Mainboards and Technicians

- Thermal Shock Resistance: Keeping Electronics Stable During Fast Charging

- Nano-Fillers: The Secret to Superior Thermal Conductivity in Modern Epoxy Resins

- Water Absorption in Epoxies — How Electrical Protection Is Affected in Real Life

- Most Costly Adhesive Failures and How Manufacturers Can Prevent Them