9 Powerful Reasons to Optimize B-Stage Epoxy: Applications, Storage, and Processing for Modern Manufacturing

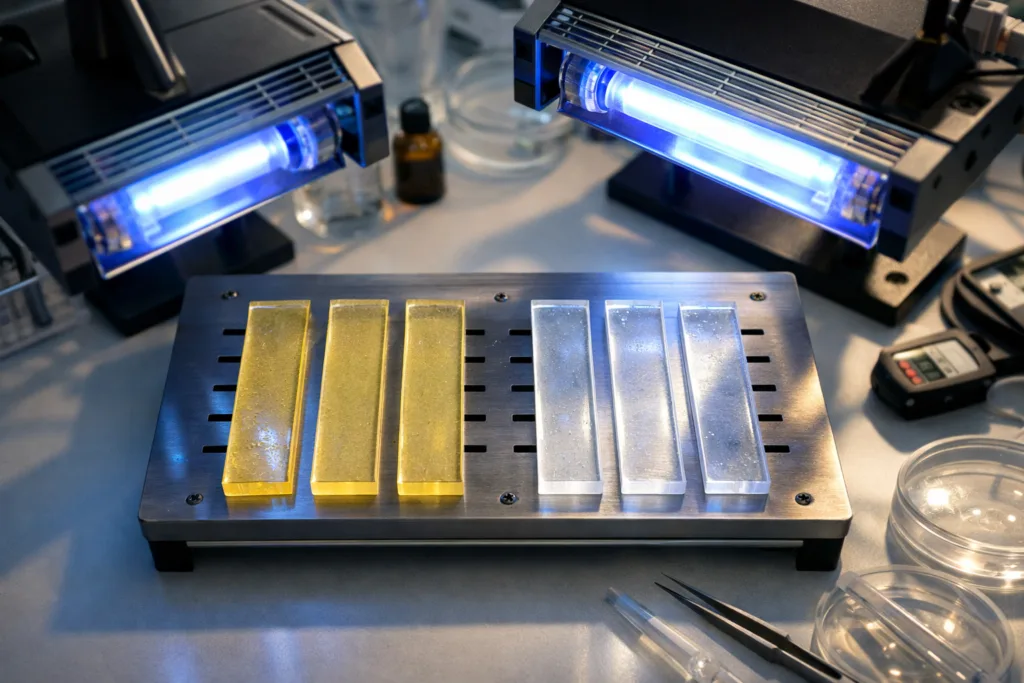

Introduction: Exploring B-Stage Epoxy and Its Industrial Value B-Stage Epoxy: Applications, Storage, and Processing is a cutting-edge topic in materials engineering, with wider relevance for electronics, construction, and automotive sectors in 2026. B-stage epoxy is a partially cured adhesive, offering the flexibility to pause production before final bonding, making it a sought-after solution in assemblies […]