In today’s advanced automotive engineering, selecting the right automotive adhesive for heat resistance is critical—especially in applications exposed to elevated temperatures, such as engine compartments, exhaust systems, and under-hood components.

ZDS™ is a trusted adhesive manufacturer providing innovative bonding solutions tailored for high-heat and performance-demanding environments. As automotive technologies evolve, so do the expectations placed on adhesives to ensure long-term performance, durability, and safety.

This guide explores key factors, types, and applications of high-temperature automotive adhesives to help you make informed choices.

Why Heat Resistance Matters in Automotive Adhesives

Understanding Thermal Stress in Vehicles

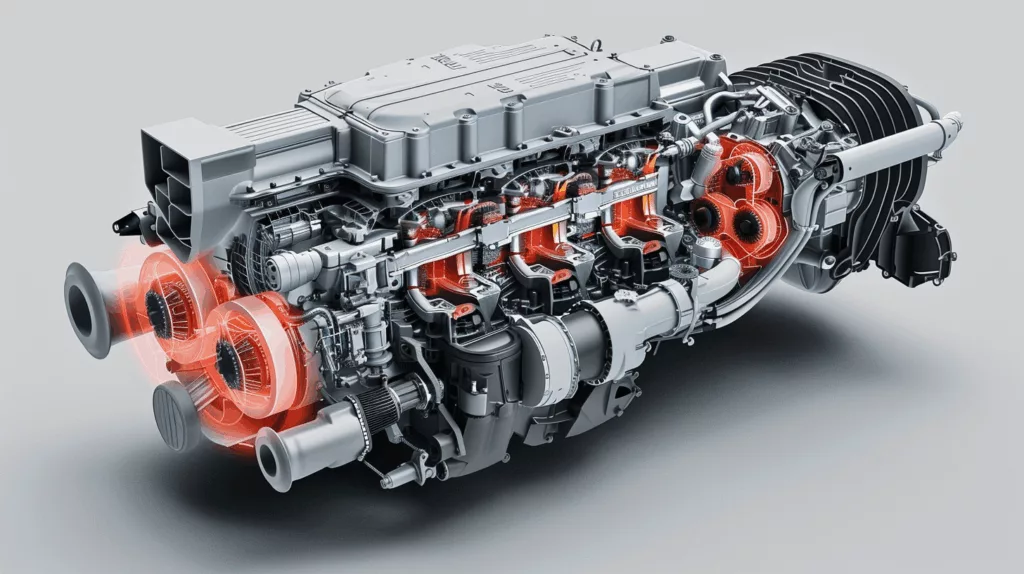

Vehicles are exposed to fluctuating and sometimes extreme temperatures. Components near the engine, brakes, or turbo systems can reach temperatures exceeding 200°C (392°F). This makes thermal stability an essential feature of any adhesive used in these areas.

Effects of Heat on Bond Integrity

High temperatures can:

- Weaken adhesive bonds over time

- Cause expansion and contraction in materials

- Lead to chemical degradation or outgassing

- Compromise safety and performance

Choosing the best adhesive for engine parts ensures structural integrity even under thermal cycling conditions.

Key Factors in Choosing a Heat Resistant Automotive Adhesive

1. Maximum Service Temperature

Check the adhesive’s maximum continuous operating temperature. For engine components, adhesives rated above 150°C to 300°C are recommended.

2. Substrate Compatibility

Not all adhesives bond well with every material. Ensure compatibility with:

- Metals (aluminum, steel, copper)

- Plastics (nylon, ABS, polypropylene)

- Composites and ceramics

3. Chemical and Oil Resistance

Automotive environments often include exposure to:

- Fuel

- Oils and greases

- Coolants and hydraulic fluids

The selected adhesive should resist these substances without degradation.

4. Vibration and Flexibility

Heat isn’t the only challenge. Vibrations and dynamic forces can stress rigid bonds. Choose adhesives with flexible or semi-rigid bonding properties where appropriate.

Types of Heat Resistant Automotive Adhesives

Epoxy Adhesives

- Known for strong bonds and high thermal resistance

- Ideal for metal-to-metal applications

- Cures rigid, can handle structural loads

Silicone Adhesives

- Flexible at high temperatures

- Performs well up to 315°C (600°F)

- Best for plastic or rubber components

Polyurethane Adhesives

- Moderate heat resistance (up to ~120°C)

- More flexible, suitable for interior and trim applications

Acrylic Adhesives

- Fast curing, good for bonding dissimilar materials

- Performs well under thermal cycling

Application Areas for High Temperature Automotive Adhesives

Engine Assembly

Used for bonding covers, sensors, and components exposed to direct engine heat.

Exhaust Systems

Adhesives must endure extreme heat and vibration, often supplemented by mechanical fastening.

Brake Systems

Require adhesives that remain stable under repetitive heating and cooling cycles.

Electrical Components

Adhesives should resist heat and electromagnetic interference while insulating sensitive components.

Testing and Standards to Consider

- OEM Specifications: Follow your vehicle manufacturer’s adhesive guidelines.

- UL 94 and ASTM D1002: Ensure fire resistance and shear strength.

- Thermal Cycling Tests: Evaluate performance over varying temperature extremes.

FAQ

What temperature can high temperature automotive adhesives withstand?

Some adhesives, such as silicones or specialized epoxies, can withstand up to 315°C (600°F) depending on the formulation.

Can I use household adhesives for car engine repairs?

No. Household adhesives are not designed for automotive heat and chemical exposure. Always use purpose-built automotive adhesives.

How do I remove heat resistant adhesives?

Use a heat gun or specialized chemical adhesive remover. Avoid scraping which can damage the substrate.

Final Thoughts: Choose Quality and Reliability

Selecting the right automotive adhesive for heat resistance involves understanding the temperature demands, chemical environment, and mechanical requirements of your application. Partnering with a proven manufacturer like ZDS™ ensures you have access to advanced, reliable bonding solutions specifically engineered for automotive use.

For long-lasting performance under high temperatures, invest in adhesives that have been tested, validated, and trusted by industry professionals.