In the high-stakes world of automotive manufacturing, speed, reliability, and performance are non-negotiable. As vehicle designs evolve to include lightweight plastics, composites, and mixed materials, the demand for fast-curing, strong adhesives has grown exponentially. Enter cyanoacrylate adhesive, a powerful bonding solution renowned for its rapid strength and versatility.

ZDS™ is a trusted adhesive manufacturer providing innovative bonding solutions across automotive, aerospace, and industrial sectors. With cutting-edge formulations and a deep understanding of material science, ZDS™ ensures that manufacturers meet performance, efficiency, and sustainability goals.

Why Cyanoacrylate Adhesives Excel in Automotive Assembly

Fast Curing for High-Speed Production

In automotive assembly lines, every second matters. Cyanoacrylate adhesives (commonly known as “super glue”) cure within seconds upon contact with moisture. This fast setting eliminates long clamping times and keeps production lines moving at peak efficiency.

Key benefits:

- No need for heat or external curing equipment

- Reduces cycle times in automated systems

- Ideal for bonding small components or fixtures quickly

Exceptional Bond Strength on Diverse Substrates

Cyanoacrylates offer high shear and tensile strength, bonding metals, plastics, rubber, and composites seamlessly. This makes them especially valuable as a plastic bonding glue in hybrid assemblies that combine different materials for weight reduction and improved fuel efficiency.

Materials commonly bonded:

- ABS, PVC, polycarbonate, and other automotive-grade plastics

- Aluminum, steel, and magnesium alloys

- Rubber seals and vibration dampeners

Engineering with High-Performance CA: What Sets It Apart?

Thermal and Chemical Resistance

Modern high-performance CA formulations provide resistance to automotive fluids, oils, and high-temperature environments—key for under-the-hood applications and interior assemblies exposed to heat cycles.

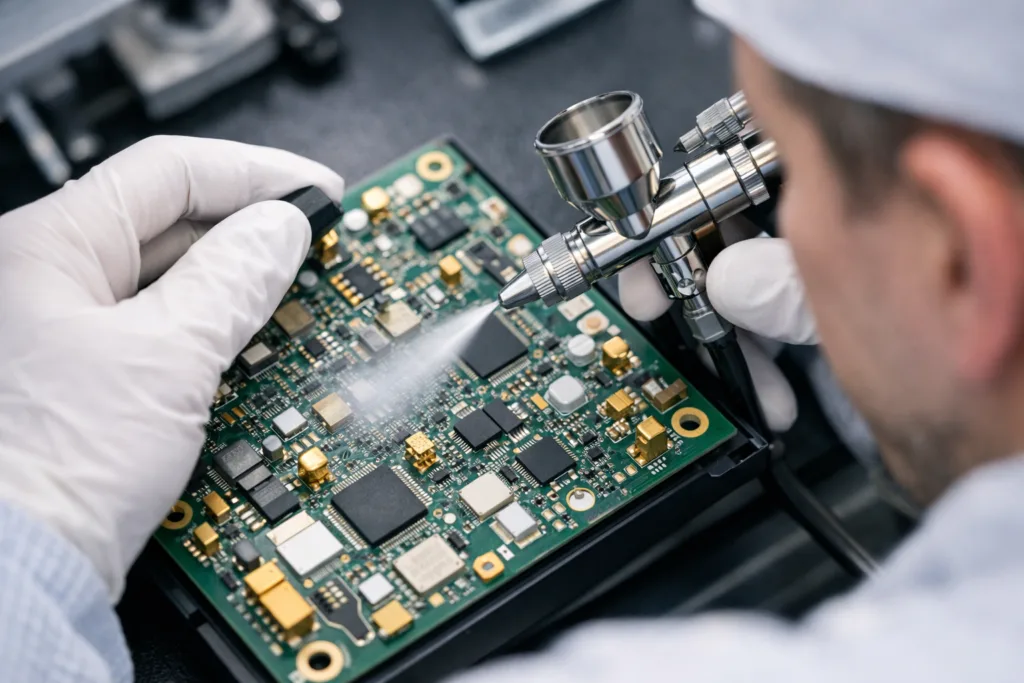

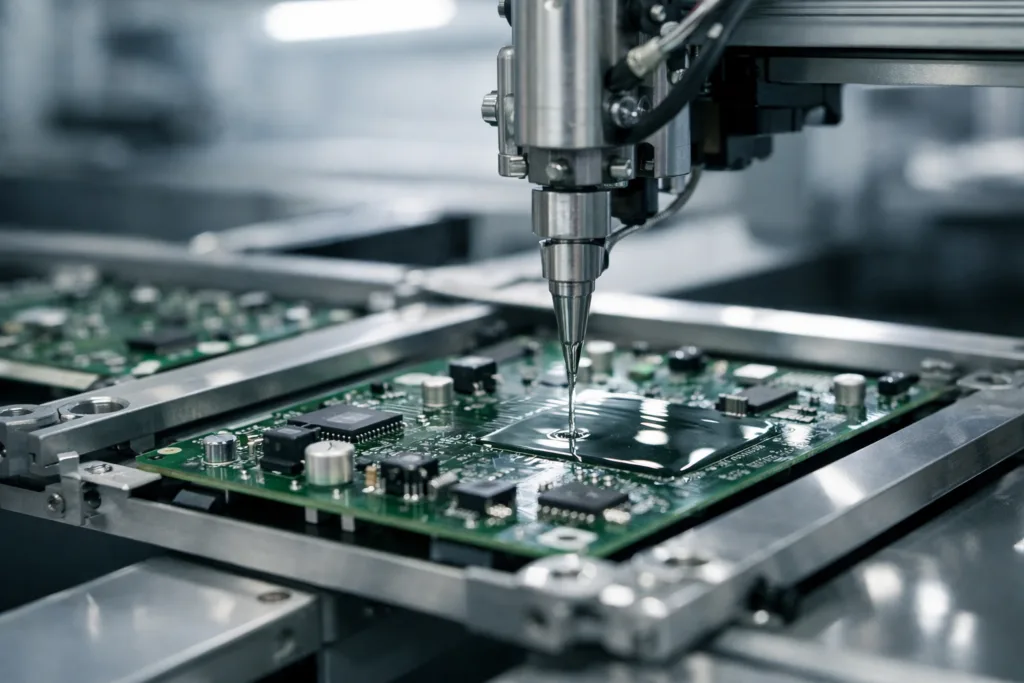

Precision Application

Thanks to their low viscosity and pinpoint dispensing, cyanoacrylates are ideal for automated micro-dosing and robotic application. This is essential in electronics, sensor assemblies, and trim installations where control and cleanliness are critical.

Automotive Applications of Cyanoacrylate Adhesives

Interior Assemblies

Used extensively to affix dashboard components, electronic modules, and decorative trim, cyanoacrylate adhesives provide an aesthetic, seamless finish without screws or mechanical fasteners.

Exterior and Under-the-Hood Use

In these high-stress areas, automotive adhesives must resist vibration, moisture, and high temperatures. Specialty CAs formulated with toughened polymers provide the resilience required.

Sensors and Electronics

With the rise of autonomous vehicles and embedded electronics, the need for low-outgassing, fast-setting adhesives is paramount. Cyanoacrylates meet these needs with unmatched speed and minimal residue.

Advantages Over Traditional Adhesive Systems

| Feature | Cyanoacrylate Adhesives | Epoxy/Polyurethane |

| Cure Time | Seconds | Minutes to hours |

| Equipment Needed | Minimal | Often requires mixing/curing |

| Substrate Versatility | High | Moderate |

| Heat Resistance | Moderate to High | High (depending on formulation) |

Frequently Asked Questions

What is the main difference between cyanoacrylate and other automotive adhesives?

Cyanoacrylate adhesives cure rapidly without heat or mixing and provide strong bonds on both plastics and metals—ideal for high-speed production.

Can cyanoacrylates replace mechanical fasteners in cars?

In many non-load-bearing applications, yes. CAs provide a cleaner finish and eliminate the need for screws or clips in interior trim and electronics.

Are cyanoacrylate adhesives suitable for plastic bonding?

Absolutely. They are among the most effective plastic bonding glues available, especially for difficult-to-bond surfaces like polyethylene or polypropylene when used with primers.

Accelerate Your Automotive Innovation with ZDS™

ZDS™ leads the way in adhesive science, offering automotive manufacturers a robust portfolio of high-performance CA solutions. Whether you’re enhancing vehicle interiors, integrating smart electronics, or optimizing assembly workflows, our adhesives are engineered for speed and strength.

Ready to elevate your automotive assembly line with precision bonding? Partner with ZDS™ for adhesive innovation that drives performance.

Related reading