Introduction: Why Coating Methods Matter for PCB Surface Finishing

Protecting printed circuit boards (PCBs) isn’t just about the quality of materials—it’s about matching the right coating method to your project needs. In 2026, engineers and manufacturers have three primary choices: dip, brush, or spray. Each approach offers unique benefits and drawbacks when it comes to ease of application, surface finishing, coverage uniformity, and compatibility with demanding environments. Whether you’re safeguarding electronics from moisture, dust, or chemical hazards, understanding how to choose the ideal coating method is the foundation for reliable PCB performance.

Comparing Coating Methods: Dip, Brush, or Spray?

Let’s dig into the three main ways to apply protective coatings to PCBs and other electronic assemblies.

| Method | Application Ease | Coverage Efficiency | Material Compatibility |

|---|---|---|---|

| Dip Coating | High (batch processing) | Excellent (all sides coated) | Works with most resins |

| Brush Coating | Moderate (manual) | Varies (requires skill) | Suitable for thick or tacky materials |

| Spray Coating | High (automated or manual) | Good (depends on setup) | Best for low-viscosity coatings |

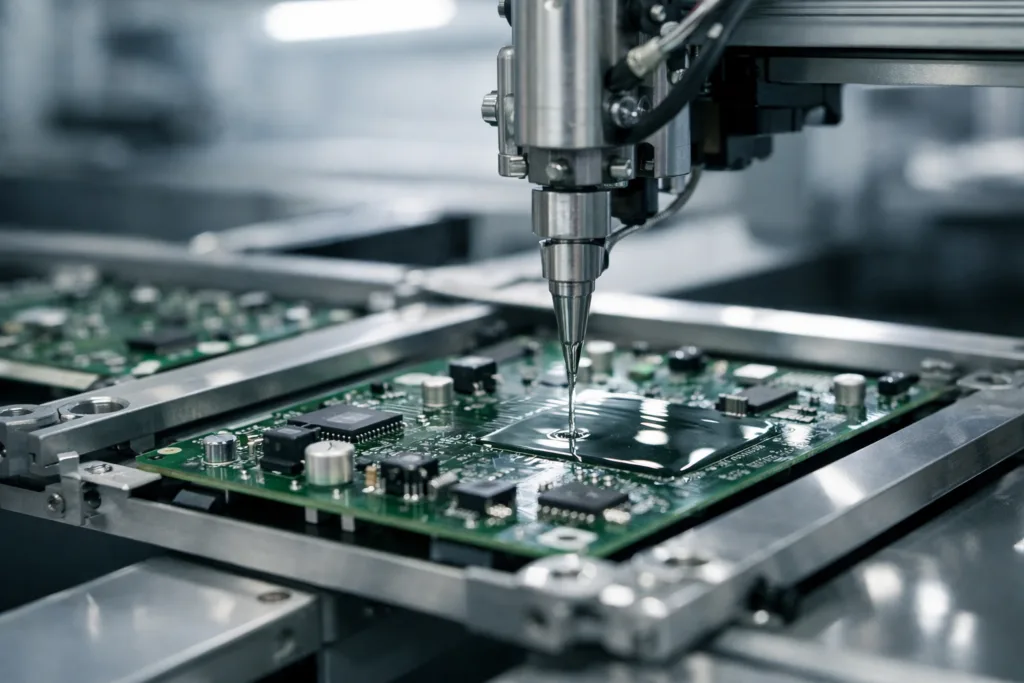

Dip Coating: Key Principles and Best Uses

Dip coating involves submerging the PCB or assembly in a bath of protective resin. This method is preferred for mass production, thanks to its speed and consistency. It works best with conformal coatings like polyurethane, silicone, and acrylic, offering full coverage—even around edges and under components. However, it’s less suitable for large boards or assemblies with complex geometries. For projects requiring rapid throughput or uniform protection, dip coating is a top choice.

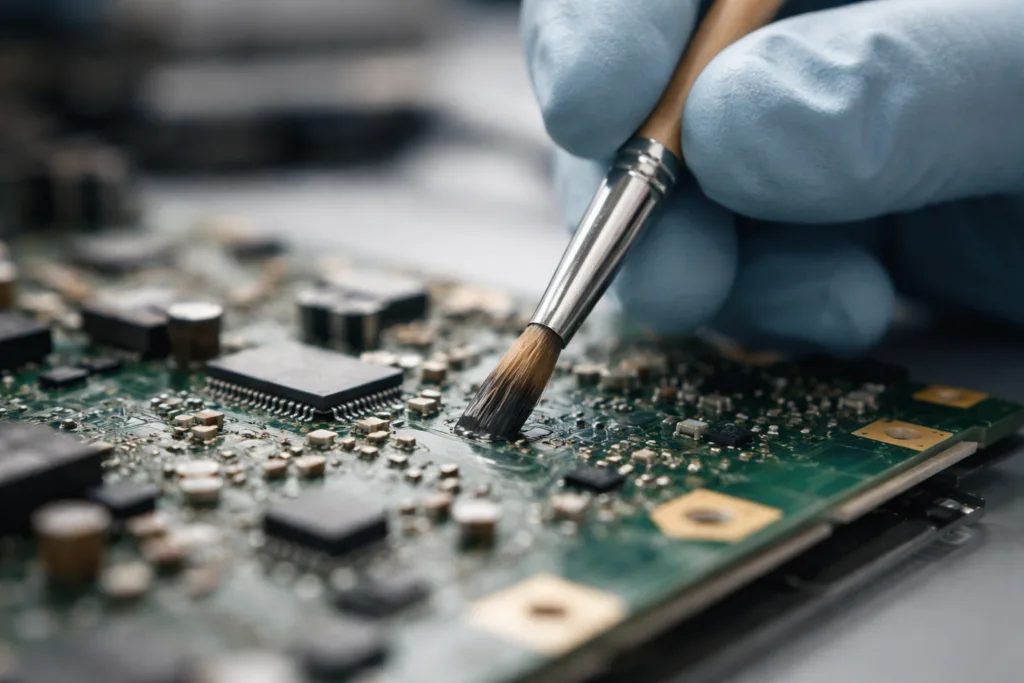

Brush Coating: Precision, Flexibility, and Control

Brush coating relies on skilled technicians to manually apply the resin. Though it’s slower, this method allows precise targeting—perfect for rework, small-batch repairs, or assemblies with sensitive areas that shouldn’t be coated. It’s useful for thicker or highly viscous coatings where spraying would be challenging. However, brush streaks or uneven layers may appear if not done carefully. For detailed PCB protection requiring pinpoint accuracy, brush coating is a reliable solution.

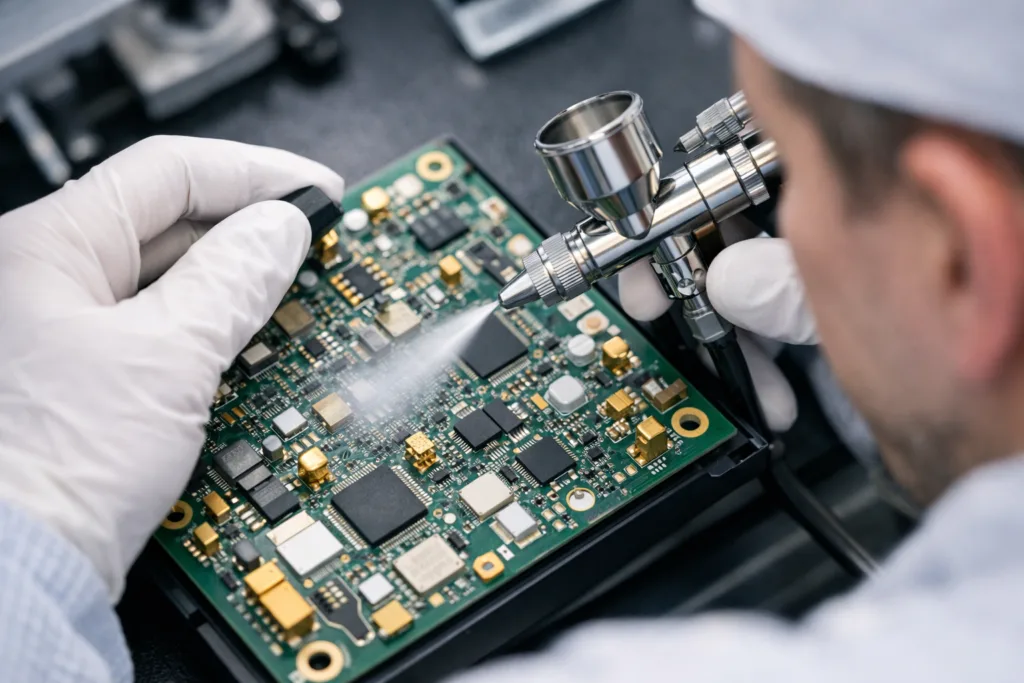

Spray Coating: Speed, Automation, and Uniformity

Spray coating can be carried out by hand or via automated systems, delivering fast application and good coverage. It’s ideal for large-scale production of medium-to-large PCBs, offering consistent thickness and a smooth finish. Low-viscosity coatings such as acrylic or water-based resins work particularly well. In controlled environments, spray methods minimize material waste and support batch processing. However, overspray, masking, and ventilation requirements must be managed to prevent defects like orange peel—see the steps to eliminate orange peel defects in conformal coating for best practices.

Industry Observations: Practical Decision Factors for Coating Method Choice

Choosing a coating method involves more than skill or tradition. Manufacturers weigh several critical factors:

- PCB Size & Complexity: Dipping works well for small, regular boards; spray is better for larger, intricate assemblies.

- Desired Surface Finish: Smoothness, gloss, or matte effects vary by method and coating.

- Operating Environment: Exposure to moisture, chemicals, vibration, or temperature extremes pushes the selection toward specific coatings and processes.

- Production Scale: High-volume runs favor dip or spray coating; prototypes or repairs often rely on brush application.

- Material Compatibility: Some methods require thin, flowable coatings; others handle thick, gap-filling adhesives.

For example, automotive electronics—where reliability under tough conditions is mandatory—may use dip coating with polyurethane structural adhesive (Polyurethane Structural Adhesive) to ensure broad coverage and resilience against moisture and vibration.

Case Study Spotlight: PCB Protection in High-Voltage Battery Packs

In electric vehicle battery modules, spray coating delivers efficient coverage and rapid processing. Yet, for smaller power circuits with deep recesses, dipping is often chosen to ensure every crevice is protected. Brush coating becomes indispensable when spot-repairing high-voltage boards after diagnostics or rework, giving technicians pinpoint control to avoid damaging sensitive areas.

Material Compatibility: Matching Adhesives and Coatings to the Application Method

Different adhesives and conformal coatings respond uniquely to each application technique. Acrylic and silicone coatings, for example, are well-suited to spraying, while polyurethane or epoxy coatings often do best with dip or brush methods. ZDS Adhesive, an industrial adhesive manufacturer, recommends verifying viscosity, cure profile, and substrate compatibility before selecting your process. For best results, conduct preliminary lap shear and peel tests, especially on assemblies subject to thermal cycling or humidity aging.

Common Defects and Troubleshooting by Coating Method

No coating method is immune to errors. Dip coating can lead to excessive buildup, missed gaps, or pooling if bath viscosity isn’t controlled. Brush applications may result in visible ridges or patchy coverage—careful technique and surface preparation are critical. Spray methods, particularly in uncontrolled environments, can produce orange peel defects, pinholes, or overspray. Managing temperature, humidity, and curing profiles is essential. For proven strategies, consult the deep guide to eliminating orange peel defects.

Coating Method Selection Checklist: Making Your Choice

- Assess size, shape, and complexity of PCB or assembly

- Identify environmental challenges: moisture, temperature, mechanical stress

- Check material viscosity and cure requirements

- Consider production scale: batch vs. single-unit

- Review finish expectations (gloss, matte, uniformity)

- Evaluate available application and curing equipment

Applying this checklist reduces costly errors and ensures optimal protection.

Dip, Brush, or Spray? Choosing the Right Coating Method Explained

The right coating method hinges on both technical parameters and practical constraints. Dip coating excels in batch uniformity and rapid throughput, brush coating wins for detailed rework or bespoke assemblies, while spray coating balances speed and coverage in medium-to-large scale production. For advanced PCB protection, new technologies—such as UV-cured adhesives and resins—offer rapid curing and enhanced durability. Interested in UV adhesives? Here’s a useful primer on UV curing adhesives for electronics assembly.

Real-World Application Examples

- Consumer wearables (small PCBs): Brush coating for precision and repairability

- Automotive ECUs (high-volume): Dip coating for fast, consistent batch processing

- Industrial controls (varied shapes): Spray coating for flexible automation and uniform finish

- Smart ring electronics: Micro-potting or brush coating chosen for reliability—check out micro-potting for smart ring electronics

Each case demonstrates process-based selection grounded in the specific needs of modern electronics.

Surface Preparation: Essential Steps Before Coating

Regardless of method, surface preparation is vital for strong adhesion and defect prevention. Dust, oils, and residues must be removed through cleaning, degreasing, or plasma/corona treatment. For further improvement in adhesive performance, see surface preparation techniques to improve adhesive strength.

Process Stability: Ensuring Consistency and Reliability

Measurable process stability is key for PCB coating reliability. Monitoring bath viscosity, spray pressure, cure times, and environmental variables is crucial. ZDS Adhesive, an industrial adhesive manufacturer, recommends using test coupons and batch records to trace defects and verify consistency after production. For high-reliability industries, maintaining this discipline preserves long-term product quality.

Optimizing Coating Performance for Modern Electronics

2026 brings new challenges and opportunities for electronic PCB protection. Next-generation adhesives, advanced curing mechanisms, and precision application tools are redefining surface finishing: enhancing moisture resistance, thermal stability, and long-term reliability. Engineers increasingly rely on data-driven choices and field feedback to select the optimal coating method. The result: safer, more robust electronics across automotive, consumer, and industrial markets.

Conclusion: Practical Takeaways for Better Coating Method Selection

Choosing between dip, brush, or spray coating requires a thoughtful blend of technical know-how and practical experience. Key takeaways: match method to PCB scale and complexity, ensure surface preparation, rigorously test for defects, and leverage industry advances for higher performance. As designs advance and demands grow, the right approach ensures ongoing protection and sustaining reliability for all electronic components.

Frequently Asked Questions

What is the most efficient coating method for mass production?

Dip coating is usually the fastest and most efficient method for mass production, offering uniform coverage and rapid batch processing.

Are brush coatings suitable for high-volume PCB manufacturing?

Brush coating is best suited for small batches, repairs, or specialized assemblies—it’s rarely used for high-volume production.

How can I prevent defects like ‘orange peel’ in spray coatings?

Controlling environmental conditions, atomizer pressure, and resin viscosity will minimize orange peel and other spray defects.

Which coatings work best with spray application?

Low-viscosity coatings such as acrylic or water-based resins are ideal for spray methods, allowing even coverage and smooth finishes.

Can dipping damage sensitive PCB areas?

Dipping coats all surfaces evenly; masking or careful fixture design is needed to protect sensitive regions from unwanted exposure.

Do coating methods affect PCB repairability?

Yes—brush and spot-coating facilitate repairability; dip and spray methods may be harder to remove without damaging underlying components.