3D Printer Resin

We make the nice UV resin for the 3D printer, since you are in the 3D printer industry, i think our UV resin will fit your needs. These include DLP/LCD 385-405nm, 395-405nm, SLA405nm, SLA355nm.

High-Temperature 3d Printer Resin, is specially formulated to withstand extreme temperatures, making it ideal for various industrial applications that require durability and reliability.

Whether you need to create heat-resistant prototypes, parts for high-temperature environments, or intricate designs that demand top-notch performance, our High Temp 3d Printer Resin Online is the perfect solution. With its exceptional thermal stability and precision, you can confidently bring your innovative ideas to life.

Jewelry Castable UV resin

For reliable casting with clean burnout and zero ash content. It is designed for both jewelry and dental casting。 Low shrinkage, high precision, Low Odor.

ABS-like 3D Printer Resin

Low Shrinkage & High Precision,Low Viscosity & Low Odor,Moderate toughness, high hardness

Ultra-High Temp 200°C Resin

With extremely high thermal resistance, high mechanical strength, and with a certain toughness.

Water-Washable Dental Model 3D Printer Resin

Water-Washable Dental Model Resin is specifically developed to rapidly produce highly accurate dental models. High Accuracy,Remove Residue with Ease,Low Shrinkage & High Precision,Low Viscosity,Low Odor

Flexible UV 3d printing resin

Strong memory retention,Semi-flexible,Superior chemical resistance,Translucent appearance,Easy to use and finish

Water-Washable 3D Printer Resin

For creating 3D printed figures, miniatures, as well as product prototypes. Remove Residue with Ease,Low Viscosity,Low Odor,Not Fragile,Environmental friendly

Water-Washable 3D Printer Resin

For creating 3D printed figures, miniatures, as well as product prototypes. Remove Residue with Ease,Low Viscosity,Low Odor,Not Fragile,Environmental friendly

Dental 3d printing resin solutions

Crown, gingival, bridge, implant model, removable model, transparent orthodontic appliance. Waterable dental mold resin, transparent surgical guide, high permeability and yellowing resistance surgical guide, soft gum resin, gum mask, tray resin, temporary crown resin (biocompatibility), Dental prosthesis casting resin, We can provide complete dental solutions.

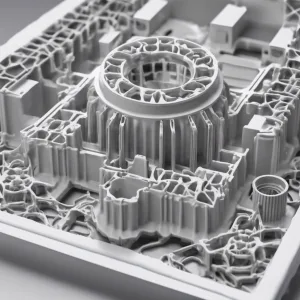

8K 3d printing Resin

8K creates high-quality & extremely intricate 3D models with 8K resolution. Low Shrinkage & High Precision,Low Viscosity & Low Odor,Wide Application

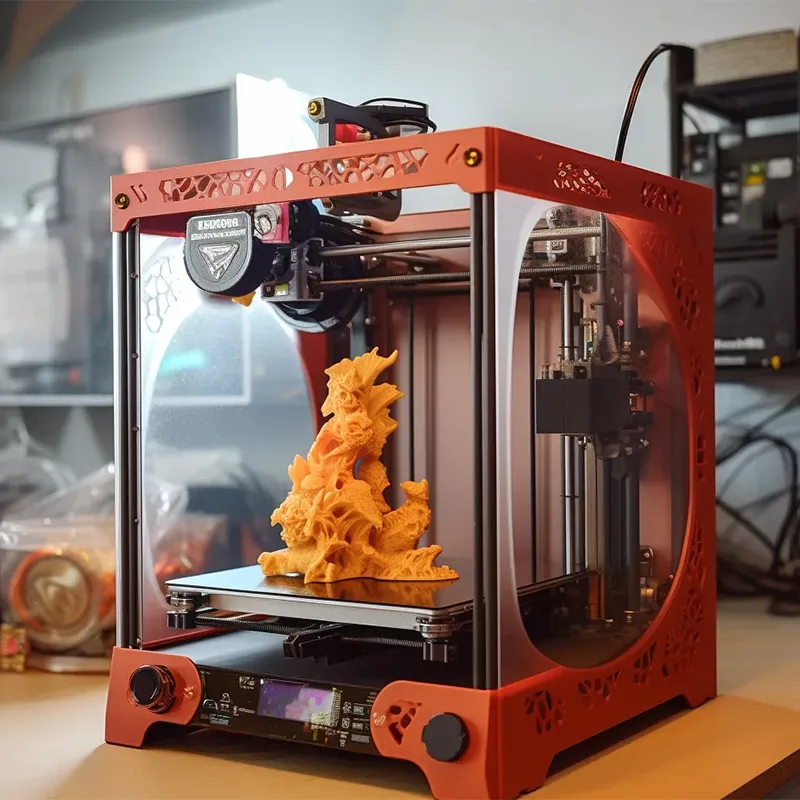

Understanding Stereolithography (SLA)

Stereolithography, commonly referred to as SLA, is a popular 3D printing technology that utilizes liquid resin to create precise and detailed 3D models. The process involves exposing the liquid resin to specific light wavelengths, typically ultraviolet (UV) light, which causes the resin to solidify layer by layer, forming a three-dimensional object.

What is 3D Printer Resin?

3D printer resin refers to the specialized material used in SLA printers. It is a liquid photopolymer resin that becomes solid when exposed to the UV light emitted by the printer. This resin possesses unique properties such as excellent print resolution, smooth surface finish, and the ability to produce intricate details not easily achievable with other printing methods.

Benefits of 3D Printer Resin

- High-Quality Prints: 3D printer resin enables the production of highly accurate and detailed models, making it ideal for prototyping and creating intricate designs.

- Smooth Surface Finish: The liquid nature of resin allows for smoother layers and finer details, resulting in a professional-looking surface finish.

- Versatile Material Options: Resins are available in various types, including clear, flexible, and durable options, allowing for a wide range of applications.

- Rapid Prototyping: With SLA technology and resin, you can quickly iterate and refine your designs, accelerating the prototyping process.

- Cost-Effective: While resin printing may have higher upfront costs, it minimizes material waste compared to traditional subtractive manufacturing methods, making it cost-effective for small-batch production.

Choosing the Best Resin for Your Printer

Different 3D printers have specific requirements for resin compatibility. ZDS Chemical offers a diverse range of high-quality resins suitable for various SLA printers. Our resins are designed to deliver exceptional print quality, accuracy, and reliability. Whether you need standard resins for general purposes or specialized resins for specific applications like jewelry making or engineering prototypes, we have the perfect solution for you.

Unlocking the Potential: How to Get Started with 3D Printer Resin

Getting started with 3D printer resin is an exciting journey that opens up endless possibilities for creativity and innovation. Here’s a brief guide to help you begin:

- Printer Setup: Ensure your SLA printer is properly calibrated and compatible with the specific resin type you plan to use. Follow the manufacturer’s guidelines for optimal performance.

- Resin Selection: Determine the resin type that suits your project requirements, considering factors such as flexibility, transparency, or durability.

- Printing Process: Load the resin into your printer’s tank, initiate the printing process, and let the printer work its magic, solidifying the resin layer by layer to create your desired model.

- Post-Processing: Once the printing is complete, carefully remove the printed model from the printer and follow any necessary post-processing steps, such as cleaning excess resin and curing the model under UV light to achieve its final properties.

With these simple steps, you’ll be well on your way to exploring the incredible potential of 3D printer resin.

Related articles

-

Warning: Undefined array key "tags" in /www/wwwroot/www.zdschemical.com/wp-content/plugins/elementor/core/page-assets/data-managers/font-icon-svg/font-awesome.php on line 45

Warning: Trying to access array offset on value of type null in /www/wwwroot/www.zdschemical.com/wp-content/plugins/elementor/core/page-assets/data-managers/font-icon-svg/font-awesome.php on line 48

Warning: Trying to access array offset on value of type null in /www/wwwroot/www.zdschemical.com/wp-content/plugins/elementor/core/page-assets/data-managers/font-icon-svg/font-awesome.php on line 49

Warning: Trying to access array offset on value of type null in /www/wwwroot/www.zdschemical.com/wp-content/plugins/elementor/core/page-assets/data-managers/font-icon-svg/font-awesome.php on line 50

ZDS

Why Choose ZDS Chemical for Your Resin Needs?

ZDS Chemical is committed to providing top-quality resin materials for 3D printers. Our extensive range of resins, carefully formulated for SLA printers, ensures outstanding print results and consistent performance. With our wide selection of resin types and exceptional customer service, we strive to meet the diverse needs of our clients and help them unleash their creativity.

Contact us today and unlock the full potential of 3D printer resin with ZDS Chemical’s premium solutions!

Frequently Asked Questions about 3D Printer Resin

Frequently Asked Questions about 3D Printer Resin

3D printer resin is a specialized material used in resin-based 3D printing technologies like SLA (stereolithography) and DLP (digital light processing). The resin used for 3D printing is typically manufactured by chemical companies or resin producers specifically for this purpose. Resin manufacturers formulate and produce the resin using various chemical components and additives to achieve the desired properties such as hardness, flexibility, transparency, or durability.

The manufacturing process of 3D printing resin involves several steps. Here’s a general overview:

- Formulation: Resin manufacturers carefully select and blend different chemical components, monomers, oligomers, polymers, and additives to create the desired resin properties.

- Mixing: The selected components are mixed together under controlled conditions to ensure proper distribution and consistency.

- Reactivity Control: The resin formulation may require photoinitiators or other chemicals to control the reactivity of the resin during the printing process, allowing it to solidify when exposed to specific light wavelengths.

- Quality Assurance: Extensive testing and quality control measures are employed throughout the manufacturing process to ensure the resin meets the desired specifications and performance standards.

Each manufacturer may have specific proprietary methods or variations in their resin production process, but these steps generally outline the overall manufacturing process.

A variety of resins can be used for 3D printing, catering to different applications and requirements. Some common resin types include standard resins, flexible resins, durable resins, transparent resins, and castable resins. Each type has unique properties suited for specific purposes, such as functional prototypes, jewelry making, or producing transparent parts. It is crucial to select a resin that matches your project’s needs and the compatibility requirements of your 3D printer.

The cost of resin for 3D printing can vary depending on several factors, including the brand, resin type, quantity, and supplier. Generally, resins designed for specific applications or with specialized properties may be more expensive than standard resins. Prices typically range from $30 to $150 per liter for consumer-grade resins, while industrial-grade resins can cost significantly higher. It’s advisable to check with different suppliers or retailers to compare prices and find the most suitable option for your budget and project.

The most common resin used for 3D printing depends on the specific application and user preferences. Standard resins are often widely used due to their versatility, affordability, and suitability for a broad range of projects. These resins offer good print quality and are well-suited for general-purpose use. However, it’s important to consider the specific requirements of your project and consult with resin manufacturers or experienced users to determine which resin type will best meet your needs.

The resin you can use in your 3D printer depends on the printer’s compatibility and the recommended resin types provided by the manufacturer. Different printers have specific requirements regarding resin viscosity, curing wavelengths, and other factors. It’s crucial to consult your printer’s documentation or the manufacturer’s website to identify the compatible resin types. Additionally, resin manufacturers or suppliers often provide information about which printers are compatible with their specific resins.

It’s important to note that resin is not an alternative to 3D printing but rather a material used in certain 3D printing technologies. When comparing resin-based 3D printing (such as SLA or DLP) to other 3D printing methods like FDM (Fused Deposition Modeling) that use filament, the cost considerations can vary. The overall cost of resin-based printing includes the price of the printer, the consumables (resin), and post-processing requirements. In some cases, the initial investment and ongoing costs associated with resin-based printing may be higher than those for filament-based printing. However, factors such as print quality, level of detail, and specific project requirements should also be considered when evaluating the suitability and cost-effectiveness of different 3D printing methods.