What Are Industrial Adhesives?

Industrial adhesives are specialized bonding agents used to join, seal, or assemble parts in manufacturing and construction. Unlike consumer glues, they deliver precision, strength, and durability under demanding conditions. Industrial adhesives enable invisible joints, lightweight assembly, and efficient automation—key drivers for industries like automotive, electronics, construction, and more.

Main Types of Industrial Adhesives

Industrial adhesives come in a range of chemistries, each offering unique properties for different needs. Selecting the right adhesive means understanding its base chemistry and how it behaves during processing and in use.

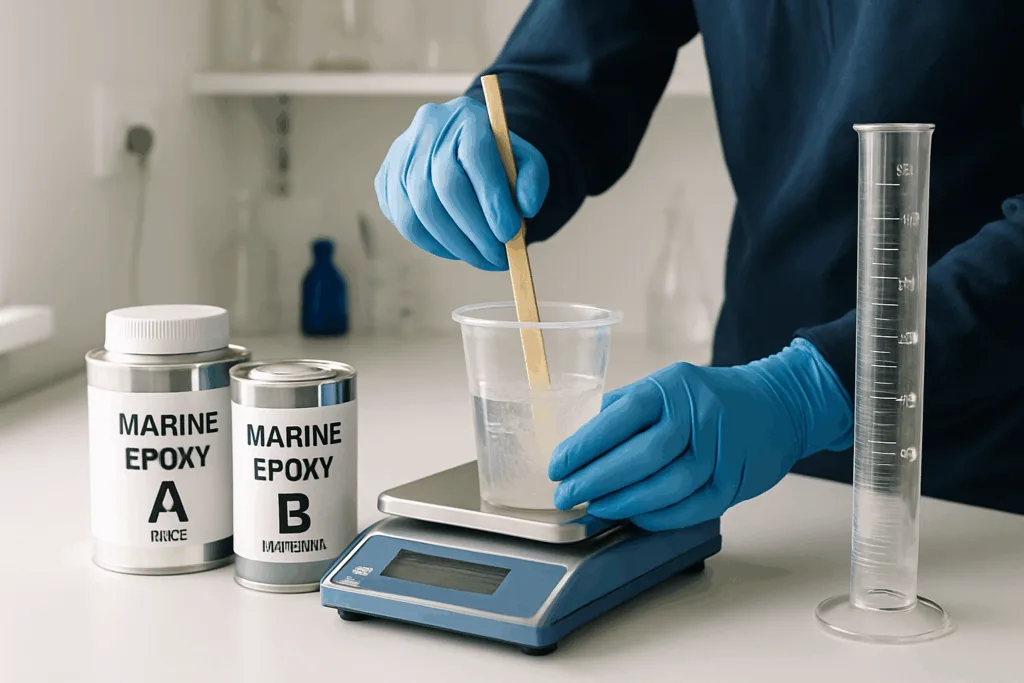

Epoxy Adhesives

Epoxy adhesives offer high strength and excellent chemical resistance. They cure through a reaction between resin and hardener—either one-part (1K) or two-part (2K) systems. Epoxies bond metals, composites, glass, and ceramics. Typical lap shear values reach 20–40 MPa. Open times range from minutes to hours, depending on formulation.

Polyurethane (PU) Adhesives

Polyurethane adhesives provide tough, flexible bonds. They tolerate movement and impact, making them ideal for automotive and construction. PU chemistries often cure with moisture. They work well on plastics, wood, and painted surfaces, with elongation up to 400% and shore hardness varying widely.

Acrylic Adhesives

Acrylic adhesives cure quickly and bond diverse substrates, including metals and plastics. They resist oils, solvents, and weather. Some systems activate with a primer, while others mix two parts. Typical uses include structural automotive components and signage.

Silicone Adhesives

Silicone adhesives withstand extreme temperatures and remain flexible after curing. Their elasticity makes them perfect for sealing, gasketing, and electronics. They bond glass, metals, and plastics, curing via moisture or heat.

Cyanoacrylate (CA) Adhesives

Also known as instant adhesives, cyanoacrylates cure in seconds on polar surfaces like plastics and metals. Their fast set enables rapid assembly lines, but bonding gaps must be very tight for best results.

Hybrid MS Polymer Adhesives

Hybrid MS (modified silane) adhesives combine durability and flexibility. They bond a wide array of substrates, including stone and flooring. These industrial adhesives maintain excellent performance in harsh environments.

Tape and Film Adhesives

Pressure-sensitive tapes and films offer clean, fast bonding for lightweight parts, electronics, and vehicles. They can be die-cut and laminated for high rates of automation. Their properties depend on carrier, adhesive chemistry, and thickness.

| Adhesive Type | Substrates | Cure Method | Key Properties | Best Uses |

|---|---|---|---|---|

| Epoxy | Metal, composite, glass, ceramics | 2K (mix), heat/RT cure | High strength, chemical resistance | Structural, automotive, electrical |

| Polyurethane | Plastic, wood, painted metals | Moisture, 1K/2K | Flexibility, impact resistance | Automotive, construction |

| Acrylic | Metal, plastic | Primer, 2K | Fast curing, weather resistance | Signage, transport |

| Silicone | Glass, metal, plastic | Moisture/heat | High temp, flexibility | Electronics, sealing |

| Cyanoacrylate | Plastic, metal, rubber | RT, moisture | Fast cure, high initial strength | Assembly, repair |

| Hybrid MS | Stone, flooring, metal | Moisture | Durability, flexibility | Construction, marine |

| Tape/Film | Plastic, metal, glass | Pressure-sensitive | Clean, fast, automation-friendly | Electronics, automotive |

Performance and Characteristics of Industrial Adhesives

Performance metrics define how well an industrial adhesive meets the job demand. These may include lap-shear strength, peel resistance, tensile strength, and elongation. Long-term durability depends on the cured state’s hardness—measured as Shore A or D—and glass transition temperature (Tg), which affects temperature resistance.

Strength and Flexibility

Some applications need maximum strength, such as bonding vehicle frames or electronics casings. Others benefit from flexibility to absorb movement—common in flooring or glass panels.

Resistance to Chemicals and Temperature

Chemical resistance matters for adhesives exposed to fuels, oils, or harsh cleaners. Temperature resistance is critical for components facing heat cycles, like engine parts or oven doors. Silicone and epoxy adhesives lead in extreme temperature resilience.

Moisture and UV Protection

Moisture and ultraviolet (UV) light can break down many industrial adhesives. Acrylics and silicones stand out for weather resistance, making them popular for exterior panels and solar installations.

Curing Process and Application Methods

Proper curing—setting into an irreversible state—turns adhesive liquid to solid. Some systems cure at room temperature, others need heat, UV light, or moisture. Pot life (time before mixing starts curing) and open time (window to apply and assemble parts) are vital for production planning.

- Beading: For joining lines with a controlled adhesive bead

- Slot-die or roll-coating: Spreads adhesive for laminating sheets

- Spraying: Applies thin films for wide surface coverage

- Notched-trowel: Spreads thicker adhesives for flooring or stone

- Static mixers: Ensures proper component blending in 2K epoxy and PU

Automation-ready adhesives can be dispensed by robots and conveyors for high-volume assembly.

Industrial Adhesive Applications Across Sectors

Industrial adhesives shape products in nearly every manufacturing field. Their use simplifies assembly, reduces weight, and opens new design choices.

Automotive Manufacturing

Adhesives bond car frames, panels, windshields, and electronic components. High-strength epoxies and PUs make vehicles lighter and safer. Hybrid systems seal seams and underbody areas against corrosion.

Electronics

Epoxy, acrylic, and tape adhesives assemble circuit boards and screens. Their precision and clean bonding allow for complex miniaturized designs. Silicone adhesives provide electrical insulation and flexible encapsulation solutions.

Construction and Building

From stone flooring to glass windows, adhesives speed installation and enhance durability. Hybrid MS polymers and acrylics deliver weather-resistant seals. Epoxy grouts anchor fixtures and tie materials together beneath the surface.

Stone and Flooring

Specialized adhesives bond stone, ceramic, and laminates to subfloors and walls. High strength and long open times allow onsite adjustment and leveling.

General Industrial Assembly

Machinery, appliances, and tools rely on adhesives for panels, surfaces, and handles. Automated dispensing ensures consistency and reduces waste.

Maintenance and Repair

Fast-setting adhesives enable quick fixes in plants and workshops. Tapes and cyanoacrylates handle urgent bonding of rubber, plastic, and metal parts.

- Reduce mechanical fastener use

- Improve vibration damping

- Protect against corrosion and moisture

- Enable automation with robotic lines

- Support flexible and lightweight product designs

For validated reliability, manufacturers like ZDS perform aging, salt spray (ASTM B117), thermal cycling, and chemical soak tests. Documentation for REACH, RoHS, and VOC compliance supports global supply chains.

Industrial Adhesives: Types, Applications, and Selection Guide

Choosing the right industrial adhesive requires matching type, substrate, performance needs, and process method. Each application should consider substrate compatibility, environment, and production speed. Below is a stepwise guide.

Step 1: Define Substrate and Surface Preparation

Adhesive success starts with clean, well-prepared surfaces. Degrease metals, abrade plastics, or grit-blast composites. Some plastics (PP, PE, PA) need corona or plasma treatment or primers for reliable bonding.

Step 2: Match Chemistry to Substrate and Stress

- Metals: Epoxy, acrylic, and PU for structural strength

- Plastics: Acrylic, cyanoacrylate, or tape/film—choose based on flexibility and cure

- Stone/Flooring: Hybrid MS and PU for durability and weather resistance

- Electronics: Silicone and epoxy for insulation/protection

Step 3: Consider Cure Time and Production Flow

Fast cures enable racing lines, while slower cures allow positioning and adjustment. Static mixers and dispensing systems automate the process in large plants.

Step 4: Test and Validate Performance

Run lap-shear (ASTM D1002), T-peel (ASTM D1876), and tensile tests. Check resistance to chemicals, temperature, and humidity using controlled chambers and salt spray.

Step 5: Meet Regulatory and Documentation Needs

Document all adhesive selections, batch numbers, and test results. Request Safety Data Sheets (SDS), traceability, and certificates of compliance to ensure safety and regulatory alignment. ZDS provides complete technical support and compliance documentation.

Expert take: “The best adhesive is the one you can trust every time. Proper selection, prep, and testing pay off in longer-lasting products and fewer failures.”

How to Find a Reliable Industrial Adhesive Manufacturer

A quality manufacturer provides more than just product. Look for technical expertise, process support, and compliance history. ZDS offers a broad catalog of structural, non-structural, and specialty adhesives with industry certifications—helping buyers optimize bonding, assembly, and automation.

- Request test data and sample kits

- Review past project references

- Check for ISO 9001 and global compliance

- Ensure support for process integration and automation

- Verify availability for tailored solutions

Quality Control and Industrial Adhesive Testing Standards

Quality assurance in adhesives depends on standard testing methods and strict manufacturing controls. Adhesive QC teams conduct salt spray, thermal cycling, peel, and tensile tests in labs. Documentation follows ISO 9001 guidelines and covers REACH, RoHS, and VOCs for global compliance.

Lot Traceability and Storage

Every production lot should be recorded for traceability. Adhesives require controlled storage—temperature, humidity, and shelf life—ensuring batch consistency.

Reliable Shipping and Handling

Adhesives ship in drums, cartridges, or rolls. Proper labeling and safety documentation reduce risks during transit and use.

Recent Innovations in Industrial Adhesives

Adhesive science advances each year. New hybrid chemistries combine the best of flexibility, durability, and safe handling. Low-VOC formulas address health and environmental concerns. Automation-ready adhesives support robotics and high-speed lines. UV-curing and ms polymer systems improve cycle time and reduce energy costs.

Smart Adhesives and Sensing Capabilities

Some recent adhesives contain micro-sensors for tracking performance and wear in real time. These are game-changers for critical industries.

Sustainable and Green Formulations

Eco-friendly adhesives, such as those based on renewable sources or with reduced emission profiles, have growing demand in automotive and consumer goods manufacturing.

Frequently Asked Questions

What defines an industrial adhesive?

An industrial adhesive is a high-performance bonding agent designed for manufacturing environments, giving strong, durable, and reliable joints across a range of materials.

Which industrial adhesive type is best for metal bonding?

Epoxy and acrylic adhesives offer excellent strength and chemical resistance for bonding metals in structural applications.

How do I prepare surfaces for industrial adhesive application?

Clean, degrease, and abrade surfaces; use primer or plasma treatment for difficult plastics; proper prep ensures long-lasting bonds.

What performance tests should I use for industrial adhesive selection?

Lap-shear, T-peel, tensile strength, aging, salt spray, and chemical soak tests all help validate adhesive performance for your needs.

What certifications should I look for in industrial adhesive manufacturing?

Look for ISO 9001 certification, plus compliance with REACH, RoHS, VOC, and reliable Safety Data Sheets for every product batch.

Can automated dispensing systems use industrial adhesives?

Yes, most industrial adhesives—including epoxies, PUs, and tapes—are available in formats suitable for robotic and automated dispensing systems.