Introduction: Why Low Halogen Epoxies Matter for Green Electronics

As electronics grow more essential and ubiquitous in everyday life, manufacturers face increasing pressure to create products that are safer for both humans and the planet. Low halogen epoxies for green electronics represent a critical innovation, enabling cleaner manufacturing and minimizing toxic risks. In this article, we explore how these specialty materials transform eco-performance, health safety, and industrial reliability, underscoring their importance in the global push toward sustainable technology.

The Need for Low Halogen Materials in Electronics

Electronic devices have traditionally relied on compounds containing halogens—chlorine, bromine, and fluorine—for flame resistance and durability. However, these substances can release highly toxic byproducts when burned or decomposed. With regulatory bodies restricting hazardous materials (like RoHS and REACH), the industry is shifting toward low halogen formulations for safer, eco-friendly devices.

Halogens in Epoxy: Benefits and Risks

Halogenated epoxies offer excellent fire protection and insulation, but they pose environmental and health risks. When halogen-rich electronics are disposed of or incinerated, they can generate toxic dioxins and furans, polluting air, soil, and water. These hazards drive demand for epoxy adhesive solutions that minimize or eliminate halogen content.

Low Halogen Epoxy Chemistry: What’s Different?

The chemistry behind low halogen epoxies centers on excluding or strictly limiting bromine and chlorine in each batch. Manufacturers use alternative flame-retardants, such as inorganic materials (aluminum hydroxide, phosphorus). This preserves thermal stability and electrical insulation, while drastically reducing environmental hazards.

Fulfilling Safety and Compliance in Green Electronics

Meeting standards like IEC 61249-2-21 (which restricts halogen content to <900 ppm bromine and <900 ppm chlorine) is essential. Low halogen epoxies help device makers comply with RoHS, REACH, and future green standards—enabling safe recycling and reducing end-of-life poisoning risks.

Key Advantages of Low Halogen Epoxies

- Reduced environmental toxicity

- Improved workplace health safety

- Enhanced sustainability and recyclability

- Stable flame-retardant performance without harmful outputs

Practical Applications: Where Low Halogen Epoxies Excel

Low halogen epoxies are now standard in industries that prioritize green credentials:

- Smartphones and tablets (PCB assembly, micro-potting)

- Wearable devices (water-resistant bonding, sweat resistance)

- Medical electronics (skin safety, electrical insulation)

- EV battery potting and thermal management

- Consumer IoT devices (conformal coating, potting compounds)

For example, recent smartphone mainboards use reworkable underfills with strict halogen caps to protect repair technicians and end users.

Environmental Impact: Lowering the Burden

Low halogen epoxies eliminate most dangerous halogen emissions in the disposal and recycling stages. Unlike halogen-heavy counterparts, these materials don’t release persistent organic pollutants (POPs), making electronics recycling safer and more sustainable. Manufacturers increasingly favor these solutions, reflected in product line certifications in 2026.

Worker Health and Safety: Minimizing Risks

For operators and assembly-line workers, cutting halogen content means fewer toxic fumes during solder rework, thermal curing, or accidental fires. ZDS Adhesive, an industrial adhesive manufacturer, recommends routine air monitoring in high-volume facilities to track improvements in workplace safety after switching to low halogen compounds.

Low Halogen Epoxies for Green Electronics: Current Standards and Market Expectations

Global brands now demand documented compliance on all new electronics. Certifications, such as UL94 V-0 (flame retardancy without toxic outputs), drive procurement. The epoxy adhesive market is responding with transparent supply chains and rapid analytics.

Comparing Low Halogen vs. Traditional Epoxies

| Feature | Traditional Epoxy | Low Halogen Epoxy |

|---|---|---|

| Halogen Content | High | <900 ppm Cl/Br |

| Flame Retardancy | Very good | Excellent, less toxic |

| Environmental Impact | Toxic outputs, POPs | Low toxicity, recyclable |

| Workplace Safety | Risk of fumes | Minimized risk |

| Compliance | RoHS partial | Full RoHS, IEC 61249-2-21 |

Innovations in Epoxy Formulation for Green Devices

Recent breakthroughs in low halogen epoxy formulations involve nano-additives, improved cross-linking, and next-gen flame retardant synergies. These advancements boost performance at lower ecological impact, a trend embraced by electronics designers in 2026.

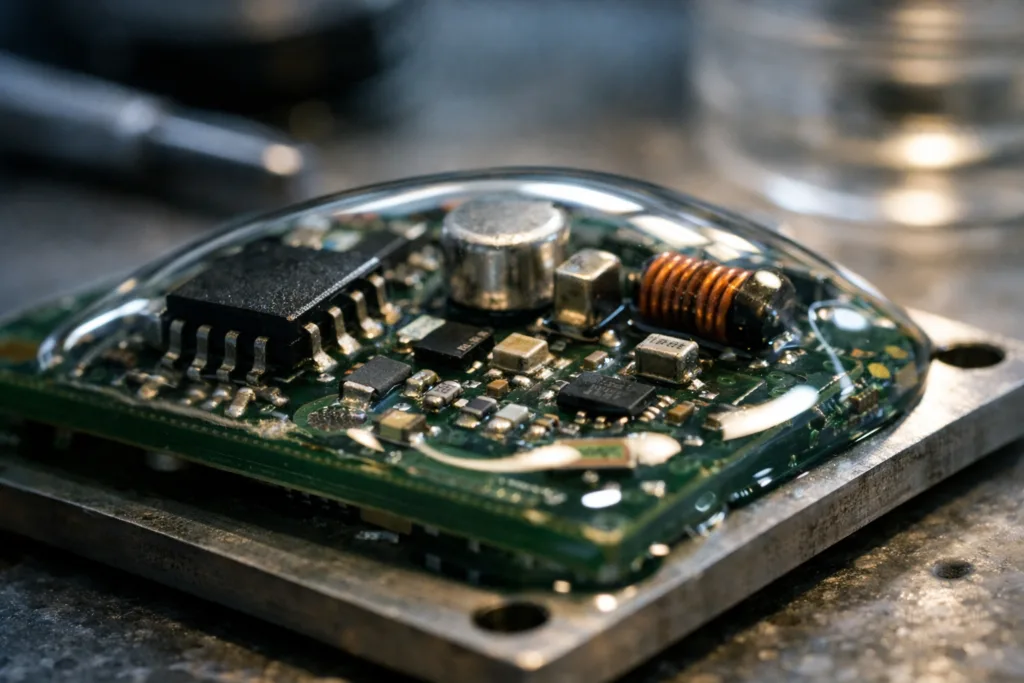

Real-World Case Study: Smart Ring Reliability and Sustainability

One example is the new generation of smart rings, which require micro-potting with low halogen epoxies for reliability, sweat resistance, and skin safety. Devices potting electronics with clean epoxies pass stringent sweat resistance tests, ensuring long-term performance and safe skin contact (micro-potting for smart rings).

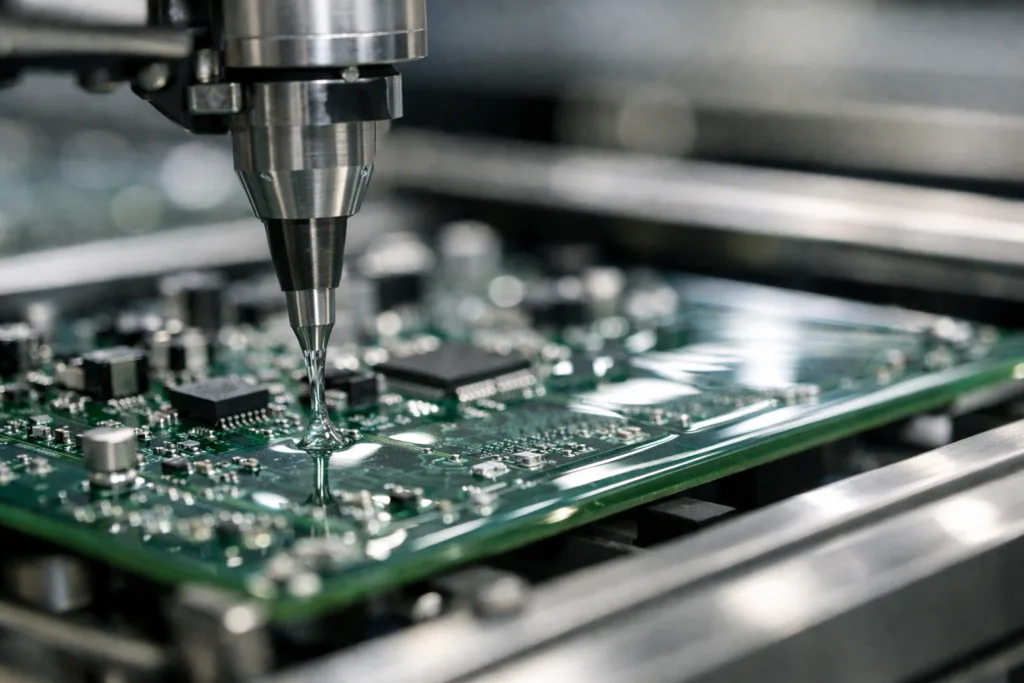

Sourcing and Quality Control in Low Halogen Epoxy Production

Quality control depends on batch testing for halogen content, flammability, and insulation. OEMs partner with trusted suppliers and demand transparent in-house analytics to ensure green labeling is legitimate—especially for mass-produced gadgets.

Challenges in the Transition to Sustainable Electronics

Despite proven benefits, switching to low halogen epoxies in electronic manufacturing can pose hurdles. These include higher upfront costs, reformulation cycles, and compatibility testing. Nevertheless, long-term savings from compliant recycling and reduced health risks justify the shift.

Best Practices for Manufacturers Adopting Low Halogen Epoxies

- Verify supplier certifications and batch analytics

- Specify flame retardant mechanisms to exclude toxic halogens

- Integrate product design with sustainable material selection

- Conduct lifecycle safety testing: electrical, thermal, chemical

Testing and Certification Procedures Explained

Industry-standard tests include IEC 61249-2-21 halogen measurement, UL94 flame rating, and lap shear/peel strength protocols. Manufacturers must document results for process audits and product safety dossiers.

The Role of Potting Compounds and Conformal Coatings

Potting and conformal coatings shield sensitive electronics from moisture and corrosion. Low halogen compounds excel as both—retaining full dielectric strength and robust environmental resistance (PCB protection choices).

Electronics Repair, Reworking, and Recycling Benefits

Low halogen formulations simplify eco-friendly device repair and recycling. They don’t generate toxic residue during rework, and post-lifecycle recycling is safer (especially for mobile devices and IoT modules).

Long-Term Reliability: How Epoxies Influence Product Lifespan

Switching to low halogen materials can mitigate risks of corrosion, electrical failure, and moisture ingress. Manufacturers report higher device reliability scores for green-labeled consumer electronics in durability tests.

Low Halogen Epoxies for Green Electronics: The Future Landscape

Market data forecasts rapid adoption of low halogen compounds across electronics categories. By 2028, nearly all new consumer devices are expected to achieve IEC 61249-2-21 compliance, driven by eco-certification demand.

Summary: Building Safer, Greener Electronics with Low Halogen Epoxies

Adopting low halogen epoxies is more than meeting regulations—it’s a proactive way to ensure product safety, worker health, and environmental protection. As technology advances, these solutions will underpin a new standard for green electronics, making sustainability and reliability inseparable.

Frequently Asked Questions

What is a low halogen epoxy?

Low halogen epoxy contains less than 900 ppm of both bromine and chlorine, meeting strict safety standards while providing flame retardant properties for electronics.

Why are halogens restricted in electronics manufacturing?

Halogens like chlorine and bromine release toxic byproducts when burned or decomposed, impacting health, air quality, and environmental safety.

Do low halogen epoxies perform as well as traditional flame-retardant epoxies?

Yes, thanks to advanced non-halogen flame retardants, low halogen epoxies maintain or exceed performance while minimizing toxic outputs.

How can manufacturers test for halogen content in epoxies?

Testing is done via analytical chemistry methods such as XRF and wet digestion, verifying compliance with standards like IEC 61249-2-21.

Are there industry examples of successful low halogen epoxy adoption?

Yes. Modern smartphones, wearable devices, and smart rings regularly use low halogen epoxies to meet green certifications and improve safety.

Is switching to low halogen epoxies cost-effective for electronics makers?

While initial costs may rise, savings in safety, compliance, and eco-friendly recycling offset expenses, especially in long-term mass production.

Related Reading

- How Sweat-Resistant Adhesives Revolutionize Wearable Electronics Longevity

- Thermal Shock Testing: The Key to Reliable Fast-Charge Adhesives

- Unlocking Storage and Efficiency in B-Stage Epoxies: What Every Manufacturer Should Know

- How Dielectric Strength Extends EV Battery Potting Life

- How Nano-Fillers Supercharge Epoxy Thermal Conductivity for Metals