Reworkable Underfill for Smartphone Mainboard Repair: 11 Key Advantages for Technicians

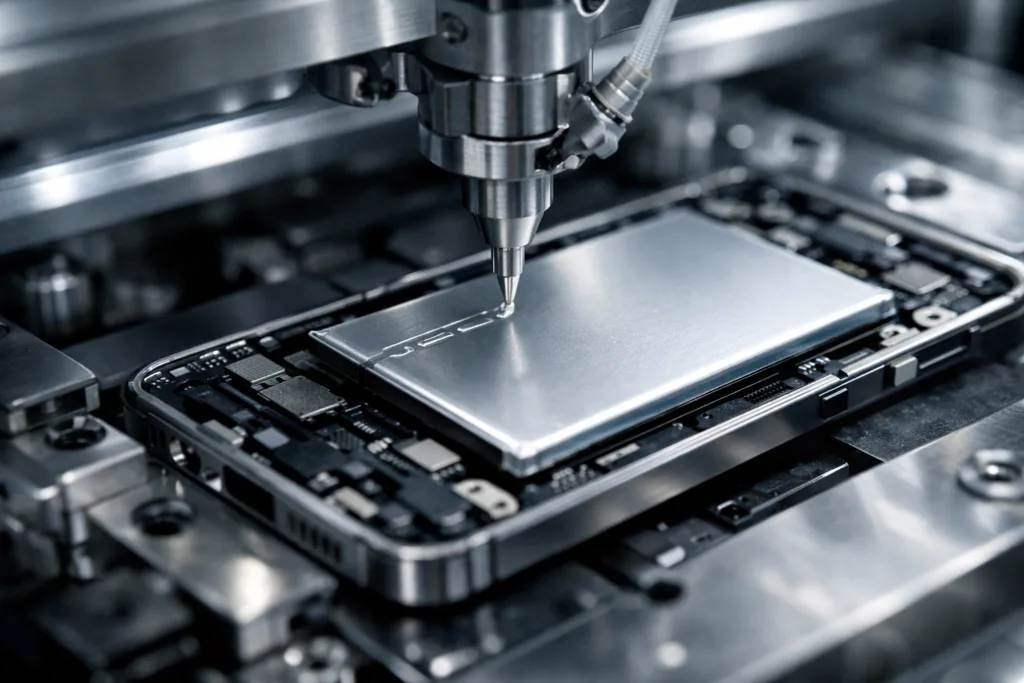

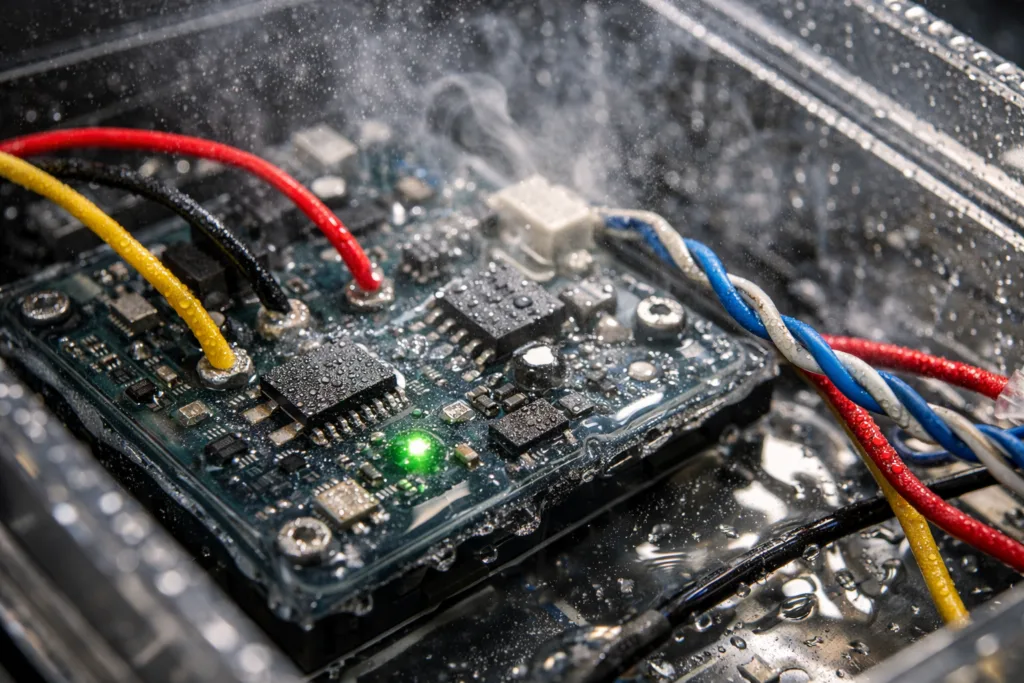

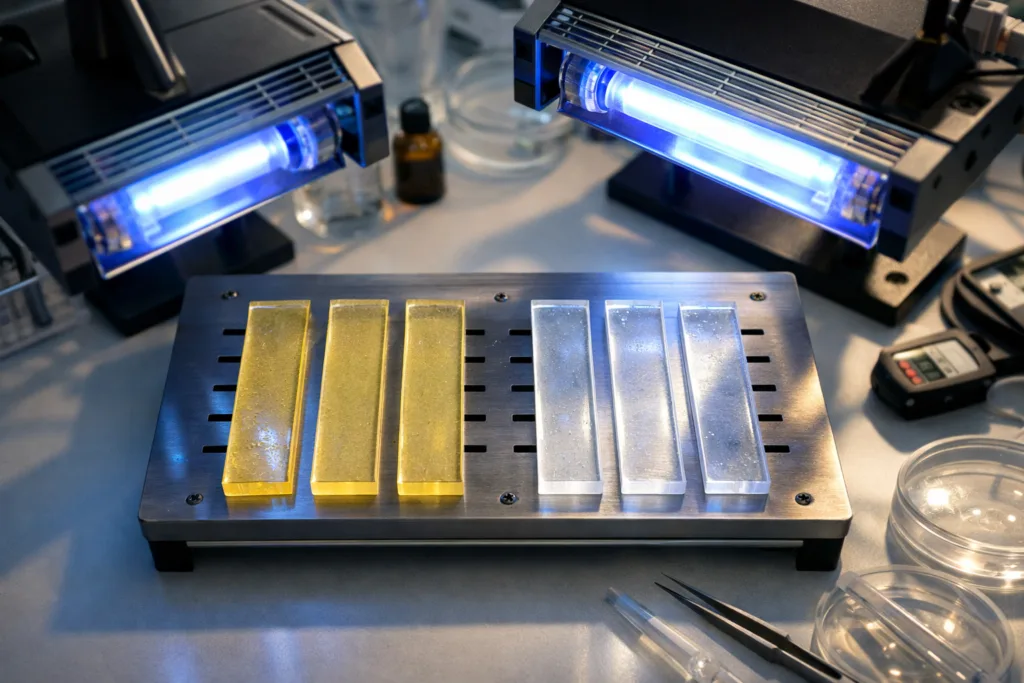

Introduction to Reworkable Underfill for Smartphone Mainboard Repair With smartphone circuit complexity soaring in 2026, the demand for reliable, service-friendly assembly processes has never been greater. Enter reworkable underfill materials—a new generation of structural adhesives specifically engineered for smartphone mainboard repairs. These advanced underfills address the pressing need for both secure adhesion and easy repairability, […]

Reworkable Underfill for Smartphone Mainboard Repair: 11 Key Advantages for Technicians Read More »